MMS Blog

External Input for Programmed Values

Parametric programming provides three easy ways to access external data.

Read MoreGenerative Design Generates New Interest in a Range of Manufacturing Options

New developments in generative design can help companies make better decisions about part design by including manufacturability as a key value. CNC milling, for example, not an additive process, might come up as the better choice for making a complex part.

Read MoreHybrid Manufacturing Requires In-Process Measurement

Hybrid manufacturing processes rely on in-process metrology both to verify that enough stock has been printed, as well as to check the final machined surface geometry.

Read MoreThe Starting Point for Machine Tool Monitoring: Data Analysis Is an Emotional Choice

For machine shops, the transformation that data-driven manufacturing promises to bring begins with machine monitoring, and there is a human component to this.

Read MoreSome Thoughts on Conflict Resolution

Understanding conflict and conflict resolution can enable a positive change in your work environment.

Read MoreFixturing for Five-Axis CNCs

For some high-batch-size jobs and/or very complex parts, custom fixtures designed and manufactured in house enable Powill Manufacturing and Engineering to get the most out of its five-axis machining capability.

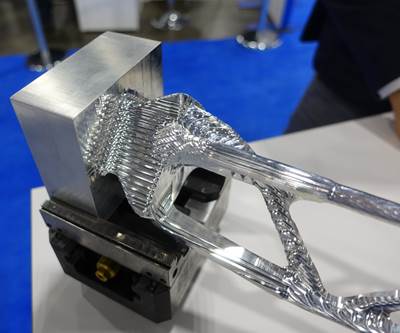

Read MoreWhat This Seat Bracket Says About the Future of Automotive Manufacturing

General Motors created a 3D-printed version of a seat bracket using generative design tools. This technology pairing will influence how cars are brought to market in the future.

Read MoreBuying a Grinder: The Abrasive Process

The prospective buyer of a new grinding machine should be aware of the ins and outs of the abrasive process, how abrasive bonds work and the various forms of wheel dressing.

Read MoreERP System Enables Gearmaker to Achieve Needed Agility

ERP software enabled a New York gearmaker to improve scheduling practices to meet the increasing demands of customers.

Read More5 Ways Automated On-Machine Probing Improves Productivity

Using automated inspection tools in CNC machining provides numerous benefits that improve productivity and reduce scrap.

Read MoreLook at Your Shop’s Progress Over the Long Term

The here and now is not always a good indicator of where you stand as a company and the positive changes you are making.

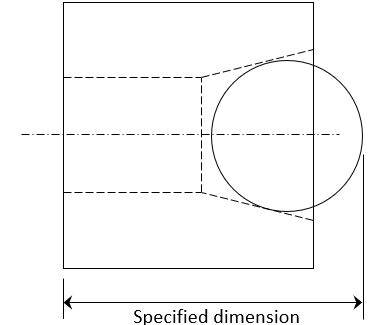

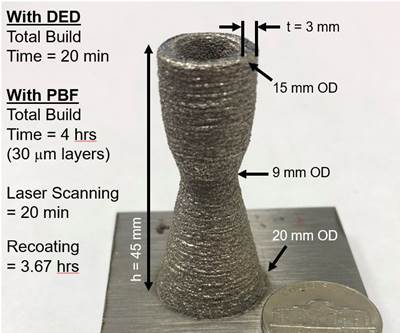

Read MoreWhat Is Directed Energy Deposition?

Analyzing directed energy deposition and powder-bed fusion provides a thorough understanding of the extra machining necessary for a “near net shape” versus a “net shape” manufacturing process.

Read More