MMS Blog

Retrofitting and Updating Keep Milling Machine CNCs on the Cutting Edge

After struggling to achieve higher feed rates and accuracy for complex milling of large compression molds, Century Tool and Gage Co. retrofitted Fidia CNC control systems onto existing machining centers.

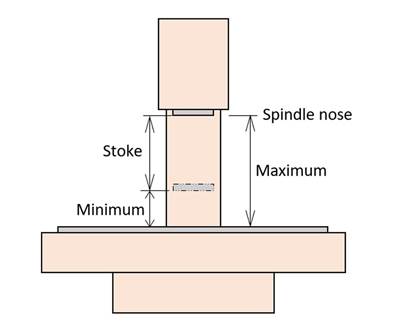

Read MoreChecking Cutting Tool Offset Values

A setup program can be used to test for overtravel issues before a workpiece is run, eliminating program verification delays.

Read MoreBuying a Grinder: Latest Technological and Process Developments

Grinders have advanced in recent years with both technological and process improvements. Here is a rundown of some of those improvements.

Read MoreUnderstanding the Internet of Things

Part of the strangeness is this: There is not much to understand! Cheap sensors, fast connectivity, and data storage and applications in the cloud all come together to simplify certain kinds of automation needs. A band saw in the lab at Georgia Tech illustrates how manufacturers might put this to use.

Read MoreNot Every RFQ Needs Your Attention

This shop discovered the most profitable thing it could do with certain RFQs is to prevent them from ever reaching the quoting team.

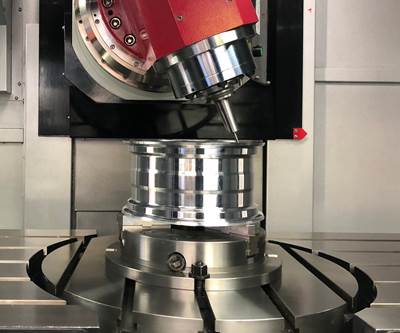

Read MoreEyeing Automotive Machining Applications in Taiwan

I took time to check out machining equipment geared toward components for automobiles—electric vehicles in particular—at the recent TMTS show in Taichung.

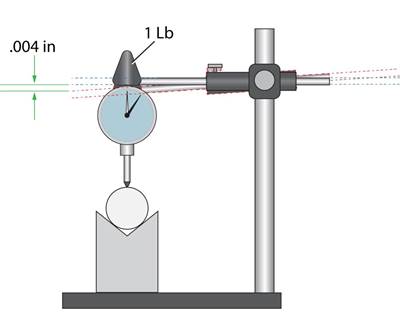

Read MoreWhy QC Inspectors Should Consider Gaging Fixture Spring Rates

All fixtures for part gaging will have some amount of deflection or spring rate that can affect measurement accuracy. A better understanding of spring rate can enable quality control inspectors to detect and eliminate this possible error source.

Read MoreWhen Machining Long Parts, Machine Shop Climate Matters

Machining long titanium tufting needle bars required a milling machine with a super-long X-axis travel. But the real challenge was thermal compensation in the Georgia heat.

Read MoreHow Manufacturers Beyond Machining Are Addressing the Skills Challenge

The need for talent in manufacturing is a challenge extending beyond just machining, and manufacturers in other sectors are finding solutions that machine shops might be able to learn from.

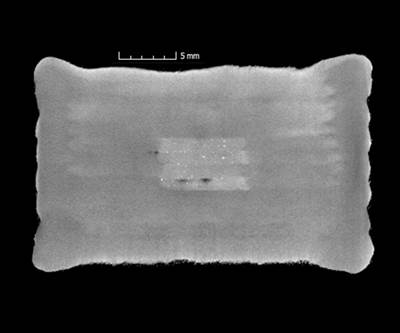

Read MoreThree Cool Uses for Directed Energy Deposition

Most machining professionals don’t like to admit that they ever make mistakes, but every now and then wouldn’t it be nice to have an “eraser” to go back and repair a gouge or fix a nicked edge? Or maybe you took off a bit too much material on that last machining pass and you’d like to add it back? Well, directed energy deposition (DED) enables you to do that and more.

Read MoreFebruary 2019 Product Spotlight: Coolant and Chip Management

This month’s Modern Equipment Review Spotlight focuses on machining coolant and chip management.

Read MoreBuying a Grinder: Applications for Grinding Machines

How are grinding machines used in aerospace, medical, die/mold and other industries? Here is a rundown of some common applications.

Read More