MMS Blog

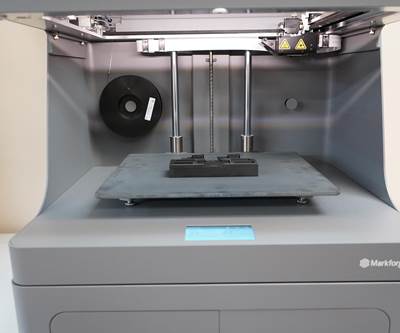

The Case for 3D-Printed Workholding: Collapsing Costs and Lead Times

When Precision Metal Products purchased its first 3D printer last year, the company hoped to collapse both tooling costs and lead times. But the technology’s impact is reaching core business operations, enabling the shop to focus on higher-margin, lower-volume production.

Read MoreAutomating Small NC Programming Tasks Pays Off Big Over Time

What started as a few Java macros the programmer whipped up to make life easier has grown to a shop-wide file management system integrated into other software, such as Vericut.

Read MoreOffline CNC Makes Precision Productive

Relieving the control of its calculation burden helps meet demand for increased volumes, faster deliveries and greater varieties of complex, mirror-finish components machined with diamond tools.

Read MoreUsing Offset Data to Determine Turret Index Position

Determine the optimal index position based on cutting tools’ current geometry offset settings.

Read MoreMachining, Disruption and the Years Ahead

Three major technological advancements have changed modern manufacturing. Pay attention or get left behind.

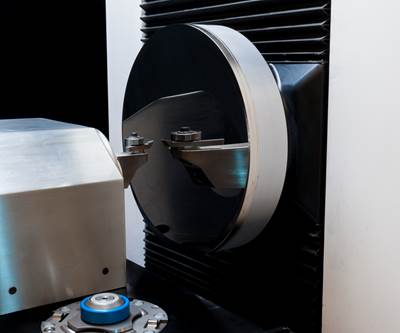

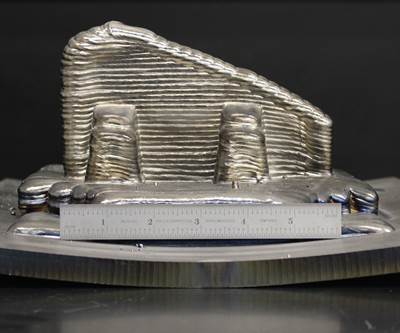

Read MoreAdditive Manufacturing with Wire

This system has the benefits of cheaper cost and easier handling. But there can be some drawbacks as well.

Read MoreFrom-Scratch CNC Post Processor Lets Dual-Toolhead Mill-Turn Shine

A dual-toolhead multitasking machine made coordination of tool paths difficult, if not impossible. A new post processor for use with Mastercam Mill-Turn resulted in smooth programming of tight-tolerance tool paths using both toolheads.

Read MoreHorizontal Machining Plus Automation Prove to Be a Rewarding Investment

After watching a machinist take four hours to set up a part on a VMC, Dan Olsen of Mach Machine knew he had a problem. The solution seemed clear: horizontal machining. The automation system wasn’t expected; but the novelty was well worth it before long.

Read MoreWhich Five-Axis Machining Center is Right for You?

With so many choices in five-axis machining technology, how do you know which is best for your shop? First, consider the parts. Then, look at existing processes and potential five-axis benefits.

Read MoreMeasuring Tools Basics: Faster and Better

In a high-volume production environment, the cost of inspection is related to the speed with which measurements can be made and interpreted.

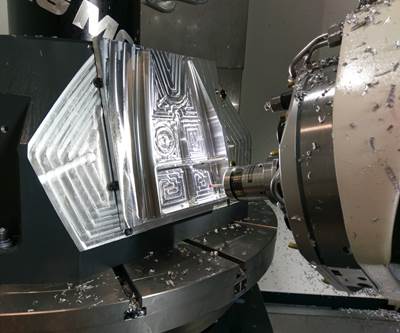

Read MoreMachining Demonstration Shows the Digital-Twin Concept in Action

A demonstration at IMTS 2018 showed that all of the pieces to meet the “Grand Challenge” are now in place, making so-called digital-twin manufacturing feasible for shops looking to streamline production of complex workpieces.

Read MoreVision Systems: One Shop's Competitive Edge for Measurement and Inspection

Even for high-volume machine shops like Alpha Grainger, every part is critical. When the bottleneck to inspect a vast number of parts resulted in lost business, the company built, then invested in, digital vision systems to gain a competitive advantage.

Read More