From-Scratch CNC Post Processor Lets Dual-Toolhead Mill-Turn Shine

A dual-toolhead multitasking machine made coordination of tool paths difficult, if not impossible. A new post processor for use with Mastercam Mill-Turn resulted in smooth programming of tight-tolerance tool paths using both toolheads.

Share

By necessity, Precision Manufacturing Solutions Inc. (PMSI) puts a lot of emphasis on the first part of its name. Since 1962, this contract machine shop has pushed itself to the limits of meticulousness in machining complex medical, aerospace and military parts, among others.

Every part that PMSI produces has extremely tight tolerances—some within 50 millionths of an inch, with true positioning in the thousandths of an inch. These parts are manufactured in a clean, climate-controlled environment. The PMSI team works with a range of materials: exotic aerospace metals; 410, 440, and 416 stainless steel; Inconel; titanium; aluminum and magnesium (a dangerous material that requires special coolant to avoid catching fire).

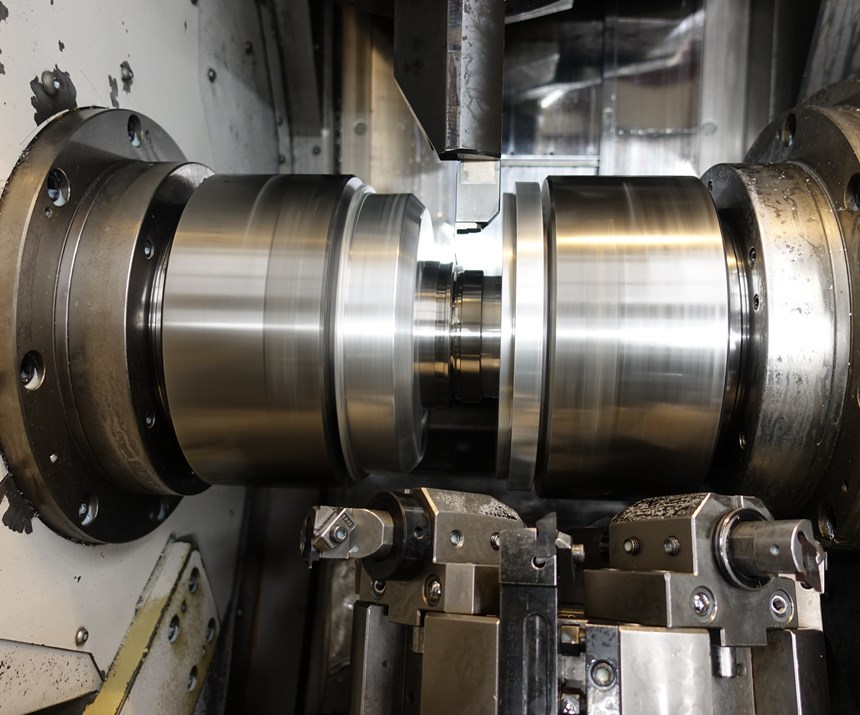

The shop uses its Mazak Integrex 300-IIIST 11-axis milling and contouring machine to machine complex components and prototypes. Developing the machine’s post processor or “post” was challenging, however, due to the machine’s dual toolhead construction. The top and bottom toolheads each required separate tool paths, and coordination between the two to create a post proved impossible: One tool path canceled out the other, creating a CNC post processor that reflected only part of the machining process.

Process Engineer Shaun McAlevey reached out to his Mastercam reseller, Cimquest, and to CNC Software Inc. for help in creating a post processor that would work on the machine. Cimquest’s Mike Slajka and CNC Software’s Pedro Sanchez, Keith Goodrich and Quanwen Du joined forces to see what could be done.

Developing a Post Processor from Scratch

Mr. Sanchez says that there were more than just a few complications inherent in the task. One of the biggest concerns he had before starting was that whatever post processor they created would need to work on all similar machines. He wanted to avoid writing code that only ran on a customized machine or that only worked with how one person ran their machine. “If we go with how the machine needs to run, then it’s generic across the board, and if we give it to another customer, it’ll run,” he says.

Even though everyone involved was dedicated to completing the task at hand, PMSI’s existing contracts had to be delivered on time. “That’s the dual challenge there as well. How can we do the post with the time the shop has available?” Mr. Sanchez says. The assignment took approximately six months to complete.

Mr. Sanchez knew from the beginning that it would not simply be a case of tweaking an old post processor. “We have a new Mastercam Mill-Turn product, so we couldn’t take the old-style post from a new engine and just convert it to a new platform. We really had to develop the whole thing from scratch.” The CNC Software team spearheaded the effort to create a brand new post processor, with Cimquest assisting and Mr. McAlevey testing and correcting their code on the Mazak machine. The crew ran tool paths as they were being formulated to check for errors, and mistakes were fixed until the post ran flawlessly.

The resulting base post processor incorporates both toolheads seamlessly and drastically reduces programming time for PMSI. It can be adjusted to work with any machine on the same platform, even for older controls. CNC Software released the Mazak Mark III post processor at the end of September, and it is currently in high demand, according to the company.

Mr. McAlevey says the machine now runs smoothly with his CAD/CAM software for cutting tough features. Mastercam now enables him to program and simulate the machining process, then get the code exactly how he wants it with minimal effort, he says.

Dynamic Tool Paths Times Two

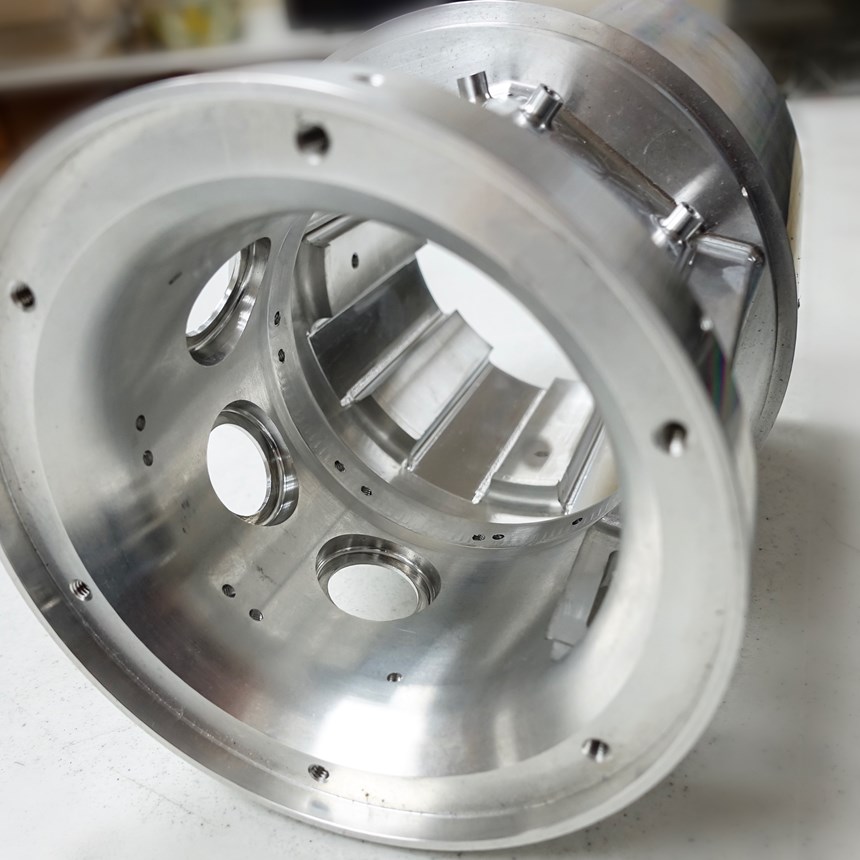

PMSI does optic machining work for the military and was recently contracted to make lens housings with specific, complex geometries. Machining these intricate parts involves tipping the tool about 30 degrees along the Z and B axes and uses a variety of end mills. Because the process strips away layers at an angle, the material undergoes high levels of stress. Parts have deformed and moved under machining in the past, making constraining the parts difficult but essential.

Mr. McAlevey depends on Mastercam’s Dynamic Motion technology to avoid excessive loads on the material while machining at high rates. Dynamic tool paths use algorithms to constantly monitor both the tool and the material. Mr. McAlevey uses mainly Dynamic Turning and Dynamic Contour to keep the chip load constant during very precise cuts where consistency is key. The PMSI team can now use smaller end tools to machine small parts with complex geometries and tight tolerances.

PMSI can feed its nine-axis machine at 300 inches per minute now. At those rates, it is imperative that the tool paths are error-free. Mazak’s Smooth platform and Mastercam’s Verify feature work together to this end. Verify enables the programmer to preview the finished part and check for any mistakes in code before machining begins.

Mr. McAlevey also uses the simulating options in Mill-Turn. Mr. Sanchez explains that Mill-Turn lets users visualize the product and the cutting operation. Using it has allowed the PMSI team to generate code and restructure their machining to better accommodate the two separate toolheads. Now the upper and lower tool paths are programmed side by side.

“I save a day or two when programming jobs just by using Mill-Turn. Working side by side with Quan and Pedro took years off of post development. It literally changed the game,” says Mr. McAlevey, though he claims that it was a team effort. CNC Software and Cimquest visited the shop twice to work alongside Mr. McAlevey while writing the post processor.

Related Content

Multitasking Machines Cut Days From Shop’s Setups

Adopting WFL Millturn machines enabled BWXT to condense operations and setups while also providing a simple way to simulate and secure processes.

Read MoreHow to Meet Aerospace’s Material Challenges and More at IMTS

Succeeding in aerospace manufacturing requires high-performing processes paired with high-performance machine tools. IMTS can help you find both.

Read MoreSwiss-Type Control Uses CNC Data to Improve Efficiency

Advanced controls for Swiss-type CNC lathes uses machine data to prevent tool collisions, saving setup time and scrap costs.

Read MoreTTI Brings Specialty Gear Production In-House with Multiaxis Machining

By investing in a 3+2-axis machine and utilizing simulation software for diagnostic checks, Techtronic Industries turned a four- to ten-week lead time into a one- to two-week lead time.

Read MoreRead Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More