Additive Manufacturing with Wire

This system has the benefits of cheaper cost and easier handling. But there can be some drawbacks as well.

Share

In my previous two columns (found here and here), we have been talking about the advantages of directed energy deposition (DED) processes for additive manufacturing (AM): How it scales well to larger components, how it can be used for repairs as well as fabrication, and how it can additively manufacture components from multiple metallic materials at once.

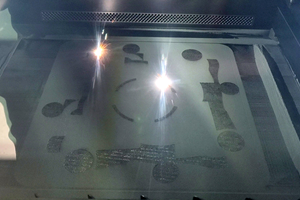

Most of the discussion has focused on powder-feed DED systems wherein powder is fed (blown) into the melt pool through small nozzles. DED systems can also use wire instead of powder for AM, and commercial wire-fed DED systems are available with lasers, electron beam and plasma arc as the thermal energy source for melting the wire.

Why wire for DED? Several reasons spring to mind. First, wire is typically cheaper to buy for DED than powder. Thanks to welding and related industries, wire is more readily available, and the price of wire ranges from 1.5 to 2x barstock versus the 5 to10x multiplier that you might find for powder. It might be even cheaper if you buy enough of it.

Second, companies often have a lot more experience storing and handling wire, which is a lot safer to handle than powder. You do not have to worry about inhalation risks, dealing with small powder particles or pyrophoric hazards common to some powders used for AM.

Material capture rates are much higher with wire-fed systems compared to powder-fed DED systems. If the process is running well, then nearly all of the wire that is fed into the melt pool melts and solidifies onto the part or into a layer within the part. This is much more efficient than the 20 to 80 percent capture rates you might get with powder.

Companies also know how to qualify wire for use in production. This helped Norsk Titanium, for instance, become a qualified Tier 1 supplier for the aerospace industry recently. This has also enabled the company to additively manufacture Federal Aviation Administration (FAA)-certified parts for Boeing. In fact, the company has since worked with SAE International to release a new standard for wire-fed DED for aerospace parts using plasma arc technology. This standard will make it easier for other companies and suppliers to qualify their wire-fed DED processes and certify parts for regulatory agencies like the FAA.

A big benefit of wire-fed DED systems is high deposition rates. When we had our electron beam wire-fed DED system from Sciaky Inc., we could deposit as much as 15 to 20 pounds of titanium per hour during a build. This is orders of magnitude faster than build rates you get on powder-bed fusion systems, which is another reason that DED systems can scale more easily for additively manufacturing large components. In fact, Sciaky’s large-format system can build parts that are as long as 19 feet or ranging to 8 feet in diameter.

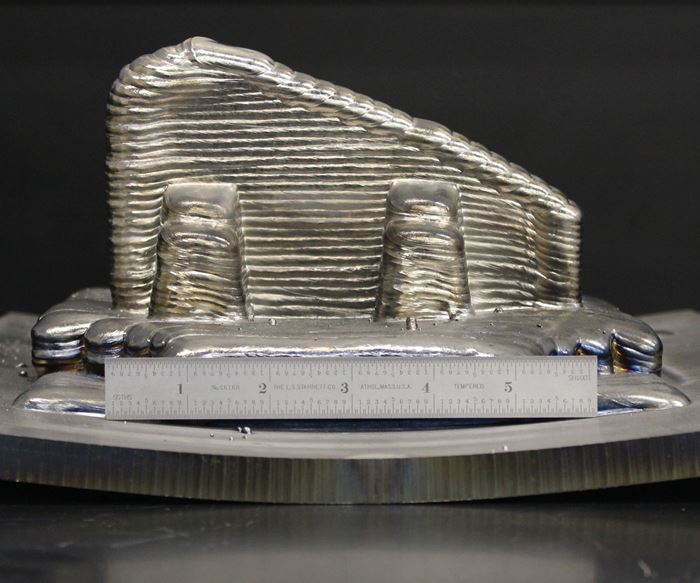

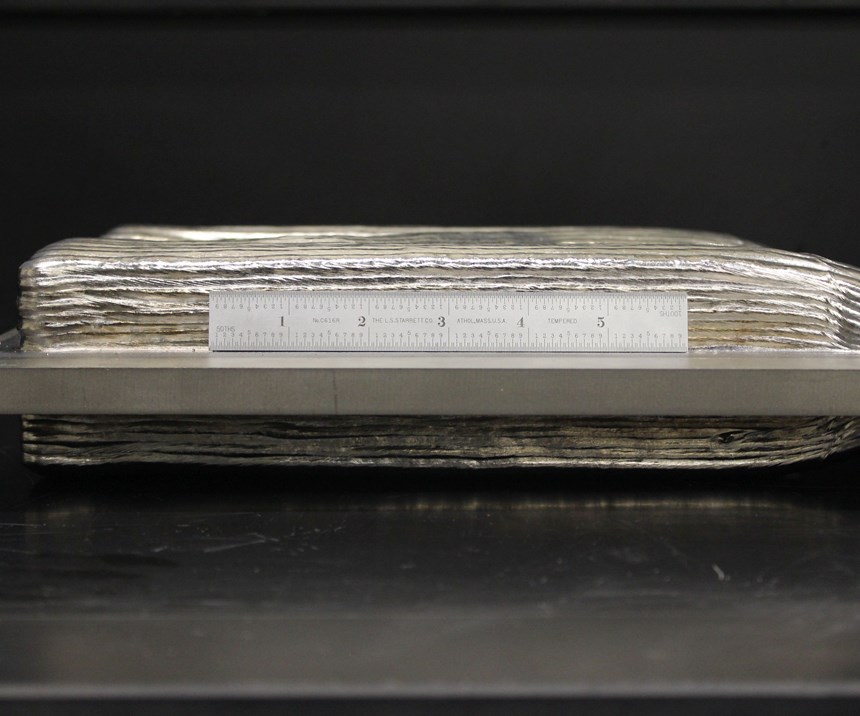

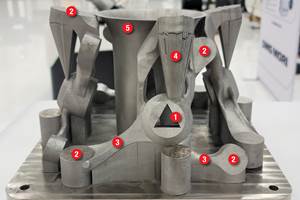

Unfortunately, the high deposition rates are also part of the downside of wire-fed DED. Think about all of the energy that is needed to melt a wire at such a high rate, and the rapid heating and cooling that occurs within the part as it is being built. The large thermal gradient leads to a lot of residual stresses in the part, which can cause significant distortion if you are not careful (see images). Luckily, simulation software can now help us detect and mitigate these distortions before they occur, and closed-loop control systems like Scikay’s Interlayer Realtime Imaging & Sensing Systems can help manage the thermal loading while ensuring a high-quality build.

Finally, the other big downside is accuracy. Parts build fast, but they are not accurate when it comes to wire-fed DED. It reminds me of icing a cake. The icing comes out quickly on the cake, but then you have to go back and smooth it down to make it look good and get the details you want. The same idea can be applied for wire-fed DED: You get a near-net shape part that will require machining and finishing to meet the tolerances, which certainly isn’t a bad thing for you machining professionals out there.

This is part three in a series about directed energy deposition.

Related Content

Designing a 3D Printed Part with Machining in Mind

Designing extra stock and mounting features into a 3D printed part can aid in machining processes downstream.

Read MoreThe Benefits of Vertically Integrating Metal 3D Printing and Machining

Having 3D printing and machining within one organization enables Addman’s engineers to collaborate and consolidate so it can quickly make successful metal 3D printed parts.

Read MoreThe Cool Parts Showcase Seeks Innovative 3D Printed Parts

Do you solve problems with 3D printing? Enter your 3D printed parts in this contest from The Cool Parts Show.

Read MoreDigital Thread Enables First-Time-Right 3D Printing

Connecting all stages of manufacturing, from design to postprocessing, helps break down barriers to industrializing additive manufacturing.

Read MoreRead Next

5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More