MMS Blog

What Makes a Top Shop?

The annual Top Shops Conference will feature expert advice on running and maintaining a successful shop.

Read MoreClosing the Loop for Better Gaging

Gages and measuring instruments come in different shapes and sizes. Whether it be a snap gage, a bench stand, a surface-finish gage or even a form system, keeping the “measuring loop” as small or as short as possible is important for better gage performance.

Read MoreReshoring News: July 2019

Tariffs shifting work back to the United States, 3D printing shows potential to reduce imports from China and more reshoring news.

Read MoreReducing Chatter with 'Weird' End Mills in CNC Machining

ANCA’s ToolRoom RN34 software improves CNC productivity through the intuitive grinding of complex end mill geometries for aerospace, die mold and power generation.

Read MoreHow Robots and Additive Manufacturing Work Together

The July issue of Additive Manufacturing magazine takes a close look at the ways automation and AM overlap, from part handling to 3D printing with robotic arms.

Read More4 Considerations for Electropolishing Machined Parts

Manufacturers considering this non-contact finishing process should expect test runs and close collaboration with service providers before production begins.

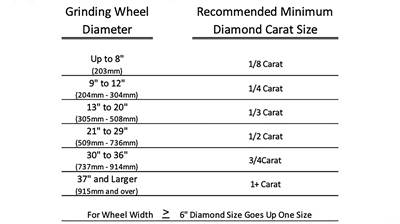

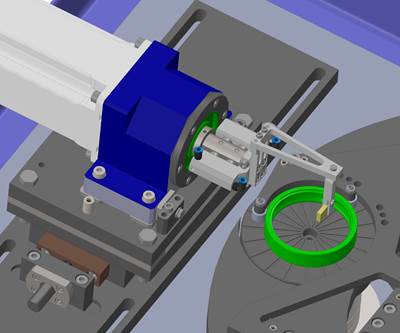

Read MoreOptimize Grinding Processes with Proper Truing and Dressing Tools

Choosing an appropriate tool and using it correctly can have a positive effect on the grinding process. However, knowing how to select a tool and what solutions are available to dress conventional grinding wheels is very useful.

Read MoreCurious About Additive Manufacturing? Tour a Facility

This year’s Additive Manufacturing Conference + Expo includes technical tours of Austin-based headquarters for EOS and Essentium. The hands-on learning experience will cover topics including metal additive manufacturing (AM), AM for production, materials testing, business changes for AM and polymers.

Read MoreSetting Up and Operating Fine Boring Heads Just Got a Lot Easier

The combination of a digital boring head integrated with tool data software dramatically reduces the time required to set up a fine boring head. And still more IIOT-enabled advancements are just around the corner that will finally automate many boring operations.

Read MoreJuly 2019 Product Spotlight: Grinding

This month’s Modern Equipment Review Spotlight focuses on grinding and abrasive machines and equipment.

Read MoreThree Face Milling Myths & Truths

New face mill designs let you get the most out of today's more powerful machining centers. If you haven't already, it's time to re-examine your assumptions on face milling operations.

Read More4 Examples of American Machining Evolution

A tour of this 160-year-old machine tool manufacturing plant in Fond Du Lac, Wisconsin, highlighted the progress of both the company and machining technology in general since the dawn of “Industry 1.0.”

Read More