Reducing Chatter with 'Weird' End Mills in CNC Machining

Sponsored ContentANCA’s ToolRoom RN34 software improves CNC productivity through the intuitive grinding of complex end mill geometries for aerospace, die mold and power generation.

Share

In a feature article on the subject roughly a decade ago, one trade magazine observed, “end mills have gotten weird.” This “weirdness” refers to new features to combat the harmonics from the cutting forces between the cutter and the workpiece in milling.

ToolRoom RN34 from ANCA was designed to enable users to easily grind end mills with complex geometries.

As users have chased higher productivity and higher quality for finished products, cutting and grinding tools have become increasingly complex. “Customers and end users are demanding and expecting to design and manufacture high-performance with complex end mill geometries at the click of a button,” observes Thomson Mathew, Software Product Manager at ANCA CNC Machines. Despite the complexity of the designs, manufacturing high-performance end mills is no longer a dream; instead, it is a real possibility with the right approach and tools.

Fighting Chatter with Advanced End Mill Design

Fighting chatter has often been the end goal of end mill design. Chatter happens when the harmonics of an end mill and a workpiece are at different frequencies, with these two objects hitting together, resulting in noise and damage. End mills have been designed to avoid or minimize chatter through variable helix/lead and pitch. Variable helix/lead with angle changes along a flute have also been used. These options can change the angle and the timing with which the workpiece is engaged.

ToolRoom RN34 is designed to enable users to grind end mills with complex geometries designed to reduce chatter and improve tool life.

Deploying any or a combination of these techniques has involved a lot of trial and error among toolmakers, which highlights the blend of art and engineering involved. The high complexity of such end mills has influenced the development of the most recent version of ANCA’s ToolRoom software suite. ToolRoom RN34 will be released in September at EMO Hannover, the premier trade show for metalworking technology.

ANCA is a leading manufacturer of CNC cutter and grinder tool machines, with 45 years of history in machine tool and related innovations. This release is the latest addition to its toolbox of technology, which includes control systems, linear motors, software, in-process measurement and even automated loading solutions with robots.

ToolRoom RN34 comes with a package of features focusing on the aerospace, die mold, general machining and power generation industries, offering improved productivity and intuitive creation of complex end mill geometries.

Differentiation for End Mill Manufacturers Through Complex Geometry

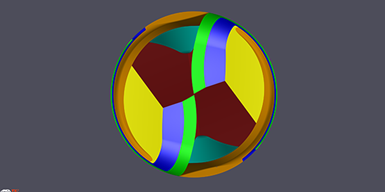

ToolRoom RN34 models end mills like this barrel-shaped cutter using 3D projections.

“ToolRoom RN34 aims to be the differentiator among many suppliers of end mill manufacturers in the industry,” says Mathew. “It enables customers to design complex geometries through software to achieve increased tool life, productivity and cutting volume, in addition to the increased quality and precision of the workpiece.”

The constant helix ballnose option, for example, is replaced by a graphical drag-and-drop designer. This ballnose-type tool has optimized, irregular helix curves to reduce vibration. With near-instant visualization, the designer easily achieves this design by switching from the 2D projection of the cutting edge to a 3D projection.

New fluting cycles have been added with these support-option combinations: variable helix and NAS, NAS and radial land, and variable helix and radial land. Per-flute programming allows for parameters to be controlled individually, including flute depth, length and taper in addition to others.

ToolRoom RN34 Chases Better Productivity

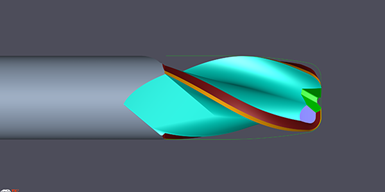

Another feature of RN34 is tool balancing, which is a valuable offering for users chasing maximum productivity. Correcting tool balance is useful in cases where the end mill has only one flute or an odd number of flutes, flutes are unevenly spaced, or when other unevenly-positioned features such as chip breakers are present. Correcting these issues can enable the tool to perform at very high speeds and feeds.

A screenshot of the tool balancing feature in ANCA’s ToolRoom RN34 software.

Another source of tool imbalance is the presence of variable helix or pitch, which can introduce uneven weight distribution throughout the tool. This makes balancing necessary at higher RPMs. Unbalanced tools can cause chatter and vibrations, resulting in tool breakage, bad surface finish on a workpiece, damage to machine bearings, and lower productivity. For further benefits, balanced tools can push up speeds, feeds, depth of cut and reduce the likelihood of unwanted vibrations and chatter.

Tool balancing in RN34 minimizes the influence of eccentric weight distribution when using high-speed spindles. It can eliminate noise and vibration, improve machine bearing life, improve surface finish on work products, and decrease the need for maintenance. “Direct communication between design and simulation software packages has simplified tool balancing and made it a breeze,” says Mathew.

Other features with the latest version of ToolRoom RN34 include revamped Tool Types like double-radius end mills, thread mills, lollipop cutters, countersink tools, pocket-grinding applications, embedded grinding files, new grinding methods, chip breaker operations, constant helix fir tree cutters, protection for grinding files, double margin drills, support for Windows10 and various other enhancements in profile software and other Tool Types.

“ToolRoom RN34 is a complete package focused on enabling end users to design and manufacture a wide range of complex tool geometries. So don’t be afraid of technology, but think about how it can be leveraged to create new levels of productivity,” Mathew says.