MMS Blog

Using AI for Predictive Maintenance, Employee Development

Maximo from IBM Watson can use "true AI" software to implement predictive maintenance and AR-assisted repair using the sensors that come standard on CNC machine tools.

Read MoreLower Buy-to-Fly Ratios with Near-Net Additive Manufacturing

Building up large parts with wire-arc metal 3D printing rather than machining from solid has allowed this aerospace manufacturer to reduce its buy-to-fly ratio dramatically.

Read MoreAre You Communicating Effectively?

Communication in your machine shop is a two-way street.

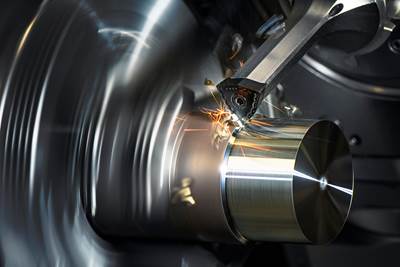

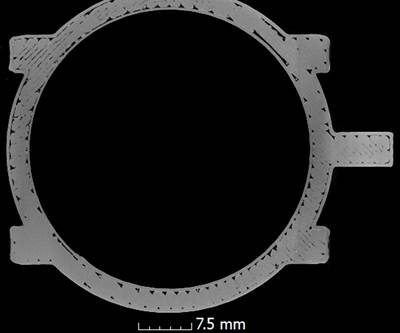

Read MoreA New Approach to CNC Turning

This turning process takes advantage of a turn-mill’s B-axis spindle to vary a tool’s approach angle to optimize chip control and feed rates.

Read MoreWhat to Include When Developing Your Company Playbook

Like a sports team, your company can also benefit from a written plan.

Read MoreShop Doubles Production Capacity with Robotic Machine Tending

In an unusual case of workers pleading for the adoption of machine-tending robots, Fusion OEM has realized great increases in capacity while freeing up machinists to more complex tasks.

Read More3 Principles for Growing with Machine Monitoring Data

Following a few basic principles can help shops get a return on their machine monitoring systems without losing faith first.

Read MoreAdditive Manufacturing Via Material Extrusion

Material extrusion was the second additive manufacturing process to be successfully commercialized. After three decades of material advancements and a diverse array of start-ups and applications, the use cases for this technology are still going strong.

Read MoreReshoring News: August 2019

Emerging market middle-class growth plateauing, Crocs could cut China production in half and more reshoring news.

Read MoreAugust 2019 Product Spotlight: Robots & Automation

This month’s Modern Equipment Review Spotlight focuses on robotic arm and related technologies.

Read MoreModern Machine Shop Announces Top Shops Honorees for 2019

Annual benchmarking program identifies best practices at best-in-class manufacturing facilities.

Read MoreA Custom Tool Data Station Eliminates Machinists' Guesswork

An otherwise well-experienced team of machinists at Fab3R was nevertheless guessing when it came to insert choice and feeds and speeds. A custom cutting tool data station now provides instant retrieval of relevant tool data in one screen within arm’s reach of the tool vending machine.

Read More

.JPG;maxWidth=400;quality=70)