MMS Blog

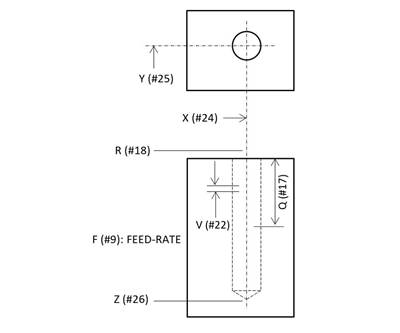

How to Improve Peck Drilling Canned Cycles

Most CNCs don’t have a canned cycle for machining deep holes into malleable materials. Here’s what you do.

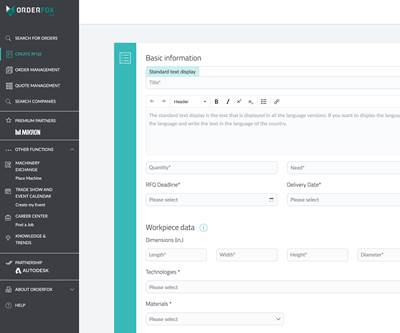

Read MoreMetalworking News of Note: November 2019

Orderfox.com adds an RFQ service for its users, Sandvik Coromant begins construction on new tech center in North Carolina, and other news from the metalworking industry.

Read MoreWhat Can 3D Printing Really Do?

And what will it mean for the future of manufacturing? “The Cool Parts Show,” a new video series from Additive Manufacturing, answers these questions with real examples. Watch the first season now.

Read MoreWhat Can 5-Axis Machining Do for Your Shop?

If you haven’t looked at 5-axis machining lately, a lot has changed. Advancements in 5-axis machines, controls and software have made this technology so affordable and easy to use that it can benefit almost any shop.

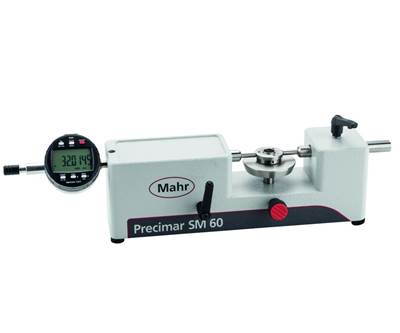

Read MoreGetting More with Digital Indicators

Today’s digital indicators are not only replacing dial indicators in some instances, but they are also approaching the performance of bench amplifiers at a fraction of the cost.

Read MoreFabricator's Toolroom Becomes Captive CNC Machine Shop

Toolroom problem-solving yields high-production profit when a sheet metal fabricating business accepts a difficult machining contract.

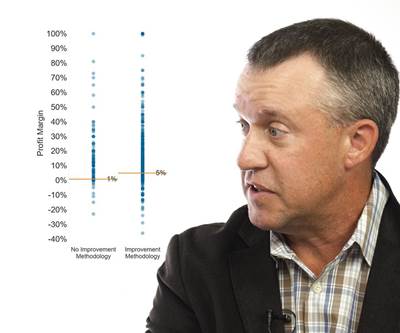

Read MoreVideo: How to Succeed at Lights-Out Machining — Findings from Top Shops Data

Differences in machine shops’ profit margins suggest the value of improvement methodology, unattended machining and machine tool monitoring, as well as the effective combination of all three of these.

Watch6 Ways to Reduce Outstanding Receivables

Are you effectively following up on your receivables?

Read MoreAn Alternative Method to Pay for New CNC Machines

Financing might be a more attractive option to using conventional bank loans or cash on hand to purchase new CNC capital equipment as one industry expert explains.

WatchA Seven-Axis Multitasking Machine Demands a CAM Software Upgrade

A new order led Forbidn Manufacturing to buy a multitasking machine, but to program it effectively required taking on Esprit CAM software. The combination produces the part in two hours instead of eight.

WatchMoldmaking Water-Flow Simulation Makes 3D-Printing Practical

Virtual prove-outs prove the worth of stirring things up, both within the cooling channels of individual molds and in the plastics industry at large.

Read MoreTour a Large New Robotics and Automation Facility

Here’s a look at FANUC America’s new 461,000-square-foot warehouse, R&D and testing facility it recently opened in Auburn Hills, Michigan.

Read More