Tour a Large New Robotics and Automation Facility

Here’s a look at FANUC America’s new 461,000-square-foot warehouse, R&D and testing facility it recently opened in Auburn Hills, Michigan.

Share

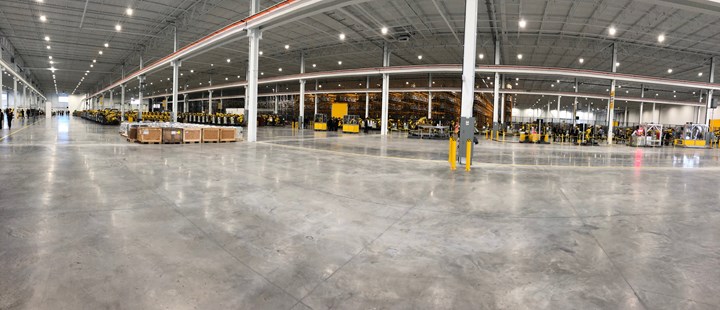

Capturing in a single photo what’s inside of a 461,000-square-foot facility is impossible, but here’s my attempt at it while touring FANUC America’s new North Campus in Auburn Hills, Michigan:

The North Campus houses several of the company’s departments, including engineering, product development, reliability testing and warehousing as I learned during a grand opening ceremony October 22. Time from groundbreaking to full operation was 364 days. With this addition, the manufacturer of robots, CNCs and factory automation systems occupies more than 1 million square feet of building space in Michigan’s Oakland County and has 25 facilities throughout the Americas.

FANUC America President and CEO Mike Cicco says the company continues to embrace what it calls a “service first” culture, noting that customer service is its highest priority. This new facility is another example of that support, he notes, as well as the growing need for robots and automation in a variety of industries.

The North Campus is one of 25 facilities the company has in the Americas.

The grand opening event included more than 20 robot demonstrations, from the company’s smallest M-1iA delta robot to its M-2000iA, said to be the world’s strongest robot with 2.3 tons of lift capacity. A variety of hands-on collaborative robot demonstrations highlighted the equipment’s simple setup and programming as well as its safe operation around humans without the protective fencing that conventional industrial robots require. Additional demonstrations included robotic solutions for assembly, material handling, packaging, palletizing, painting and welding. In fact, I learned about a special arc welding application that will be unveiled at Fabtech this November, but I’m not letting the cat out of the bag here.

Click through the slideshow above to see some of what I saw at the grand opening.

Related Content

-

Investing in Automation, Five-Axis to Increase Production Capacity

To meet an increase in demand, this shop invested heavily in automation solutions and five-axis machines to ramp up its production capabilities.

-

Cutting Part Programming Times Through AI

CAM Assist cuts repetition from part programming — early users say it cuts tribal knowledge and could be a useful tool for training new programmers.

-

4 Steps to a Cobot Culture: How Thyssenkrupp Bilstein Has Answered Staffing Shortages With Economical Automation

Safe, economical automation using collaborative robots can transform a manufacturing facility and overcome staffing shortfalls, but it takes additional investment and a systemized approach to automation in order to realize this change.

.jpg;maxWidth=300;quality=90)