Metalworking News of Note: November 2019

Orderfox.com adds an RFQ service for its users, Sandvik Coromant begins construction on new tech center in North Carolina, and other news from the metalworking industry.

Share

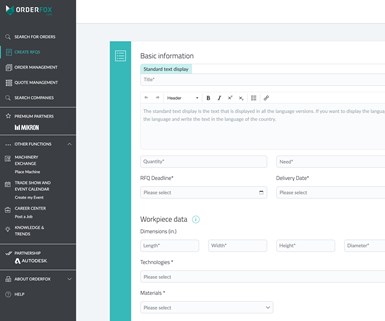

Orderfox.com has launched a free RFQ placement service designed to assist buyers in creating requests for quotes. The move is in line with the company’s goals of digitizing manufacturing work processes by giving buyers access to manufacturers’ extra capacity.

“Providing buyers a streamlined service for helping them post and manage their RFQs to reach a broader market is a strategic goal that helps the industry holistically,” says Brian J. Smith, president of Orderfox.com America. “Orderfox.com was conceived to benefit both manufacturers and buyers by finding them the right production partners quickly and efficiently.” He adds, “We are not here to reduce manufacturer’s revenue with high commissions, forced pricing or hidden fees, we pride ourselves on 100% transparency.” Read more.

Here is some other industry news to note:

- Sandvik Coromant to Build Tech Center in Mebane, North Carolina – The location is central to the company’s aerospace and automotive customers as well as three large research universities. Read more.

- Okuma Announces New Standard Warranties on Machines, Controls – The standard warranty now includes coverage for all Okuma core and high-tech products as well as OSP and FANUC controls. Read more.

- NRTC Automation Launches iGAM.com to Sell Pre-Owned Robots – The e-commerce website enables users to find and purchase reconditioned robots, manufacturing equipment and robot parts. Read more.

Related Content

-

Generating a Digital Twin in the CNC

New control technology captures critical data about a machining process and uses it to create a 3D graphical representation of the finished workpiece. This new type of digital twin helps relate machining results to machine performance, leading to better decisions on the shop floor.

-

Computer Programming-Related Features of Custom Macro

Custom macro is an interpreter-based language, meaning that all CNC G code and custom macro commands are executed as the CNC comes across them.

-

4 Commonly Misapplied CNC Features

Misapplication of these important CNC features will result in wasted time, wasted or duplicated effort and/or wasted material.

.jpg;maxWidth=300;quality=90)