Share

“How does my business compare to other, similar businesses?” is the central question we set out to ask 10 years ago with our first Top Shops benchmarking survey. We’re still answering that question. However, the program has evolved over the years to include an honor given annually to distinctive shops and even a series of events. Here is a brief look at Modern Machine Shop’s “Top Shops" and what it means to us today:

First, benchmarking. The most recent annual survey brought in responses from nearly 300 North American CNC machining businesses. We use the data to score each shop according to select, weighted metrics. A high score indicates high overall performance four categories: machining technology; shopfloor practices and performance; business strategy and performance; and human resources. Those scoring in the top 20th percentile are deemed “Top Shops.”

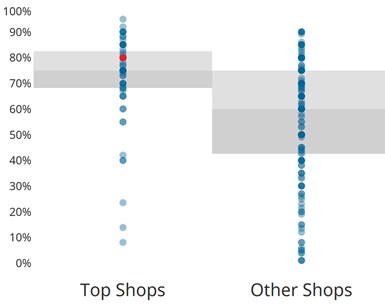

Our reports now feature a more graphical format. This chart plots spindle utilization.

These surveys always have offered more than just a measure of performance. The data also reveal what characteristics generally define top performers. To name a few examples, the upper echelon of machining businesses are more likely to offer bonus programs for employees, adopt five-axis machining technology, and use software for scheduling work.

However, much has changed. In fact, the reports issued to each survey-taker now are almost unrecognizable to anyone who has not participated since before 2018. Rather than table after table of numbers, reports are graphical and tailor-made for each individual shop. Comparisons of specific metrics, such as spindle or capacity utilization, can be made at a glance.

Were you aware that sales per employee is highly correlated with not only overall shop profitability, but also the use of a tool presetter? Insights like this are available in regular webinars by Steven Kline, chief data officer at Gardner Intelligence, shown here at the 2019 Top Shops Conference.

The evolution of the survey aside, Top Shops has also become more than a benchmarking program. As depicted in the surrounding images, it is also an experience. It is regular webinars that present key insights from the data. It is also a community of shops, technology suppliers, distributors and more. Recent interest in our data from state governments suggests it might even be a tool for broader economic development. Finally, Top Shops is editorial pieces like this one, which serve to educate the industry about what we do aside from publishing articles and, ideally, spur more North American CNC machining business to act.

The third annual Modern Machine Shop Top Shops Conference concluded in Cincinnati on September 11, 2019. More than 100 companies came to network and gain actionable insights through an extensive technical program, a series of panel discussions and more.

By “we,” I mean not just MMS, but our publisher Gardner Business Media, and specifically, Gardner Intelligence, the team behind the data analysis that provides the insight behind the data and reports on its findings.

We also cover the program’s participants, particularly the four Honors program winners. For example, 2020’s machining technology winner, Advanced Precision Engineering in Ipswich, Massachusetts, stands out for the breadth of the equipment on the shop floor as well as the extent of its recent investments. In Livermore, California, Pacon Mfg, Inc. uses technology to drive a lean manufacturing process. Tier One Machining and Assembly in Newtown, Connecticut, is notable for a shop culture that earned it the human resources win, while Rimeco Products in Willoughby, Ohio, won the business strategy category for carving a market niche and bringing its own products to market.

Of course, all four of these shops stand out in all four categories, as does any shop deemed a Top Shop. Likewise, any Top Shop likely has something to teach. We aim to continue bringing you those insights from survey participants who are willing to testify about their success. We will also continue to report on the insights that Gardner Intelligence, the business unit of Modern Machine Shop Publisher Gardner Business Media that is responsible for analyzing the data, will continue to bring in years to come.

Related Content

Top Shops: Designing a Shop to Meet Customer Needs

Working closely with customers and making careful investments has enabled this Wisconsin machine shop to tackle difficult jobs with tight deadlines as a core part of its business.

Read MoreCreating a Learning Culture at JD Machine

JD Machine, 2024’s Top Shops Honoree in Human Resources, embodies its “Education for Life” core value with a robust apprenticeship program and significant continuous improvement efforts.

Read MoreSame Headcount, Double the Sales: Successful Job Shop Automation

Doubling sales requires more than just robots. Pro Products’ staff works in tandem with robots, performing inspection and other value-added activities.

Read MoreRead Next

What Makes a Top Shop Profitable?

The data from Gardner Intelligence's Top Shops survey can show us how technology and management tools relate to earnings and profit in machine shops. Register for this webinar to learn about some of the specific findings from the survey.

Read MoreThe Tie Between Technology and People

Top Shops data analysis shows that investment in employees more directly correlates to profit margin than investment in equipment. Still, careful consideration of new technology matters.

Read MoreTop Three Questions about the Top Shops Benchmarking Program

Our ninth annual Top Shops online benchmarking survey is now live. Here I answer three common questions I receive about it.

Read More

.jpg;maxWidth=300;quality=90)