What Do Manufacturers Really Know About the Surfaces of the Parts They Are Producing?

Knowing only the average roughness may not be enough. Other surface parameters can affect product quality.

Share

ECi Software Solutions, Inc.

Featured Content

View More

Autodesk, Inc.

Featured Content

View More

Takumi USA

Featured Content

View More

By design, averaging systems filter out all surface components except roughness—the pattern of tool marks caused by turning, grinding, milling or other machining processes. However, if manufacturers only know average roughness (Ra), they may not know nearly enough. Other potential surface problems often created during the manufacturing process, such as waviness, may not be revealed. If left undetected, these surface parameters could directly affect product quality.

With today's high production costs and increasing demand for improved product performance and reliability, this is a critical situation. Yet, most workpiece specifications for surface finish still require only average roughness measurement, relying on instruments that don't reveal the true surface characteristics.

The Case of the Cranky Crankshafts

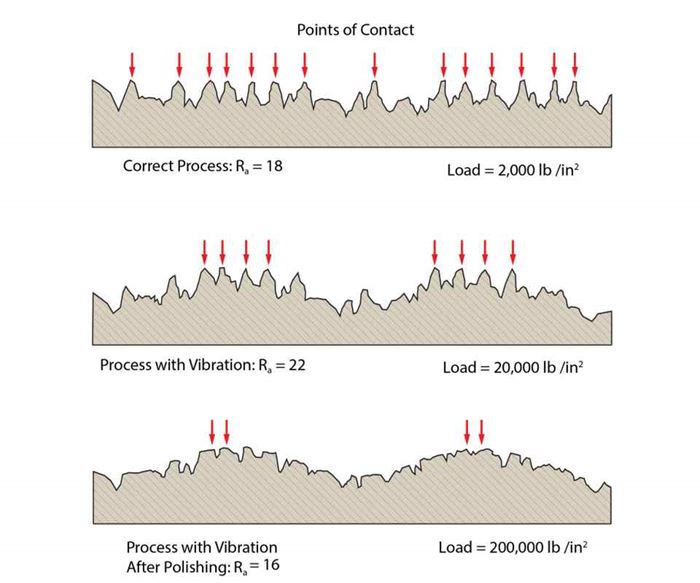

A crankshaft manufacturer was suddenly faced with exploding high-performance engines and many angry customers. A check of the surface roughness on crankshaft journals being machined showed an increase from 18 to 22 microinches on one production line.

After normal corrective procedures failed to get the finish back down to 18 microinches, the manufacturer changed the production process by adding a polishing operation and successfully reducing the average roughness to within specification. The results of this change, however, were disastrous, with the number of rejects jumping from 6 to 98 percent.

Normally, with an 18-microinch average roughness, journal loads were approximately 2,000 pounds per square inch. Profiling showed that the change in roughness readings to 22 microinches was accompanied by lower-frequency waviness, which altered the part geometry. In effect, the normal contact area between the journal and its bearing was significantly reduced, increasing the load to 20,000 pounds per square inch.

Polishing only reduced the contact area, further compounding the problem. The load was then multiplied tenfold, to 200,000 pounds per square inch, causing the crankshafts to crack in less than 200 hours of use. Once discovered, the waviness was traced back to a vibration caused by out-of-round bearings in one of the machine tools on the production line. (See Figure 1.)

The Case of the Compromised Computer Disk

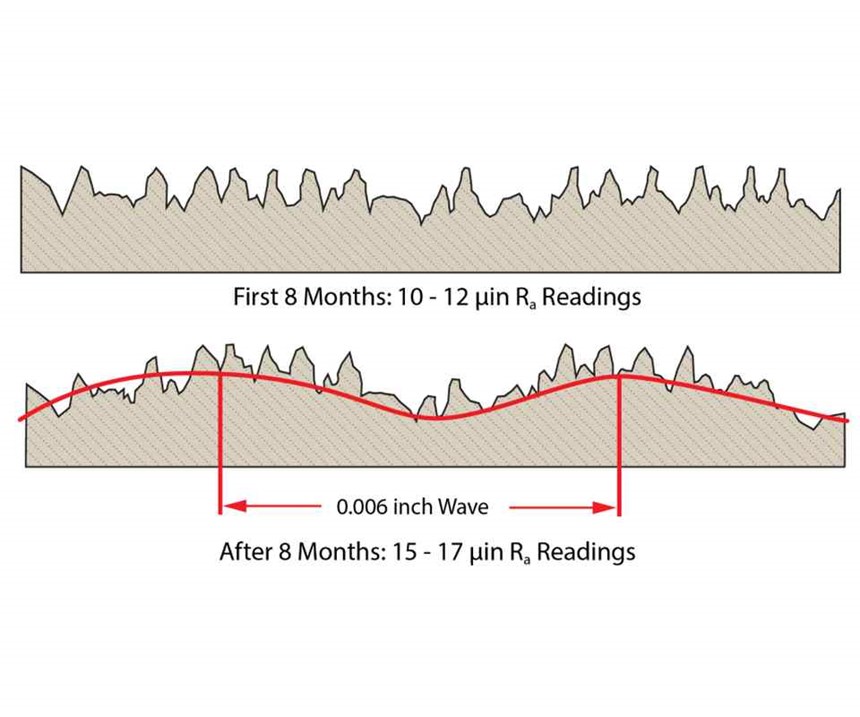

After grinding computer disks using the same process for more than eight months, one manufacturer developed a serious problem. Suddenly, the surface-finish readings (average roughness) dramatically from between 10 to 12 microinches to 15 to 17 microinches, an increase of 50 percent.

Corrective actions, including dressing the grinding wheel, changing the coolant, redressing the wheel and changing the grit, did nothing to remedy the situation. Eventually, a profile of the surface was taken, revealing the problem: a wave measuring 0.006 inch, peak-to-peak. (See Figure 2.)

After extensive investigation, the company determined the cause to be an eccentric shaft in a large air conditioning unit on the roof that vibrated the plant structure as well as the machinery. Such a low-frequency vibration from outside the grinding process was not detected with average roughness equipment.

The Moral of the Stories

While it has a lot of value for qualifying surfaces, the Ra parameter has shown to be a compromised parameter in many cases. Problems, especially with fine surfaces, arise when manufacturers measure only the Ra without having a full understanding of its limitations and the proper selection of cutoff. Most of these problems are easily solved after making a profile of the surface.

Modern surface-finish-measurement equipment can provide a total picture of the surface, extracting each component of a surface profile for individual and comparative analysis. It can separate higher-frequency surface roughness from lower-frequency waviness to detect reasons for any changes in microinch finish during the manufacturing process.

The ability to record and examine total profile of a surface and analyze any of its components can help a manufacturer establish and maintain surface tolerances critical to product performance. Today, achieving optimum surface finish is more than desirable; it is essential.

Related Content

How to Evaluate Measurement Uncertainty

Manufacturing and measurement are closely coupled. An important consideration for the use of measurement results is the associated measurement uncertainty. This article describes common metrology terms and provides an example uncertainty analysis.

Read MoreProcess Control — Leveraging Machine Shop Connectivity in Real Time

Renishaw Central, the company’s new end-to-end process control software, offers a new methodology for producing families of parts through actionable data.

Read MoreTurning Fixed-Body Plug Gages Inside Out

Fixed-body mechanical plug gages provide fast, high-performance measurement for tight-tolerance holes.

Read More6 Machine Shop Essentials to Stay Competitive

If you want to streamline production and be competitive in the industry, you will need far more than a standard three-axis CNC mill or two-axis CNC lathe and a few measuring tools.

Read MoreRead Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read More

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)