Share

Autodesk, Inc.

Featured Content

View More

Takumi USA

Featured Content

View More

The shop floor at Rekluse is lined with VersaBuilt's Automation Systems. Rekluse has 26 total VersaBuilt systems on its floor. Photo Credit: VersaBuilt

About a decade ago, Rekluse had a problem. The Idaho-based maker of aftermarket motorcycle clutches deals with cyclical business. During the summer months, bikers are out riding, and they use the winter months to work on their bikes, making whatever improvements they can before the days get longer and the warm weather invites them to ride again.

This leads to Rekluse’s business doubling during the winter when people are ordering parts to work on their motorcycles or dirt bikes and thinking about every possible way to improve their summer riding experience.

To deal with this shift in demand, Rekluse would hire temporary help to run machines during the winter.

It turns out that temporary help wasn't good for business. The new operators were less productive and prone to making mistakes, which lowered the company's margins at a time when it should have been most profitable.

This problem led Al Youngwerth, who founded Rekluse in 2002, and his team to explore ways to introduce flexible capacity. At that time, Rekluse had about 250 parts in its portfolio. Serving multiple motorcycle OEMs that occasionally changed clutch assemblies while trying to innovate its own technology means that some aspects of part design change yearly.

These factors made it tricky to find a solution to Rekluse’s problem. After a bit of searching, Youngwerth met with House of Design, a robot integrator in Nampa, Idaho, about 20 miles west of Boise. Together, they collaborated to form a solution: robots that load both workholding and workpieces for machining centers.

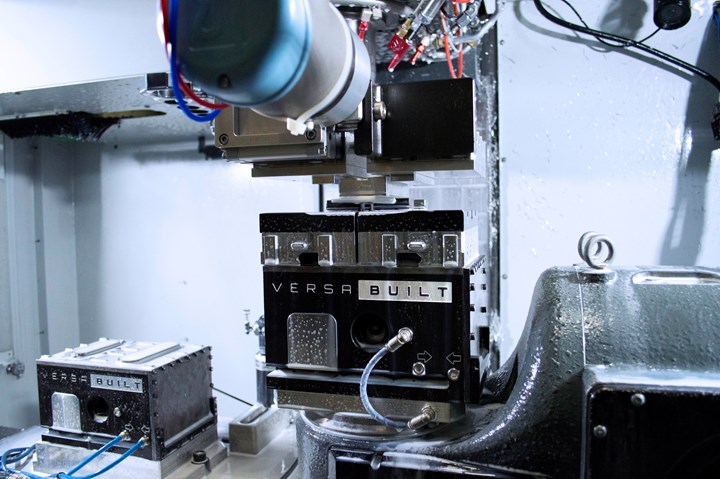

This idea resulted in the creation of VersaBuilt, which now offers these flexible solutions to other shops. VersaBuilt created the VBX-160, a robotic machine tending system that automatically loads and unloads parts for processing in machining centers. It has a rack system, a robot located inside the cell, a controller that interfaces with the robot and machining center, and a rinse-and-dry system for cleaning parts.

VersaBuilt’s latest automation system, and Rekluse’s latest purchase, the Mill Automation System, utilizes several features of the VBX-160, replacing the industrial robot with a UR10e cobot and swapping the rack system with a cart that can be moved from machine to machine. Utilizing the cobot removes the need for a skilled robot technician and allows operators to maintain the system.

Considerations for Evolving Automation

Rekluse only needed a handful of these robot-fed machines to go from shipping orders eight weeks late during the winter months to pushing through its busy season without getting behind. Now, Rekluse has 26 VersaBuilt automation systems.

Using VersaBuilt’s products, Rekluse has seen uptime improvements while requiring less labor hours per machining hour. The shop has staff on-site during the day to load the automation systems and perform preventative maintenance, and then machines run up to 18 hours straight as needed to keep up with demand. This covers the seasonal demand swings by running machines longer as needed.

Before Rekluse could implement this automation setup, though, there were some steps to take. Sean Brown, Rekluse’s VP of engineering and innovation, says that in order to make a robot work in a CNC machine, the company first had to integrate pneumatic vises into the machines. This led to other considerations.

The VBX-160 and Mill Automation System come with CNC files that include a table wash program for chip management as well chip wash stations outside the CNC. Photo Credit: VersaBuilt

“You’ve got to anticipate chip control. How do I keep the fixtures clean? How do I evacuate the chips? How many parts can I run before the machine needs cleaned out? These are all things — depending on the volume of work you’re doing — that you’re going to have to go through and manage,” Brown says.

In addition to all of that, Rekluse still must train people on loading the parts into machines in case the automation solution experiences downtime. In fact, Brown says the need for ongoing training while beginning the automation process was one of the biggest surprises he noticed on a general scale.

“Automation is still relatively new for some people, so, getting comfortable with it and how our process works is a big part of it,” Brown says. “To make the whole system work, you’ve got to really understand tool life, you’ve got to understand chip control in the machines and how the operator is interacting with the part. Because that changes.”

With more standardized processes in place to allow the automation solutions to work effectively, Brown says spindle crashes and machine crashes are almost non-existent now, which has led to less downtime, too.

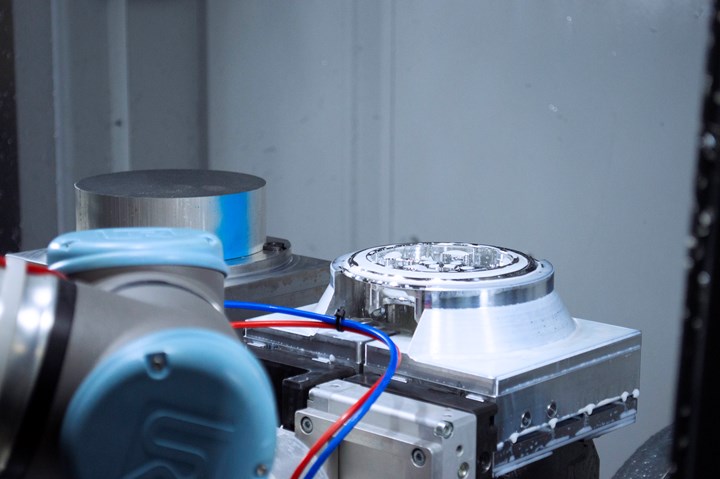

The VBX-160 and Mill Automation System use VersaBuilt’s MultiGrip vises and soft jaws to hold parts. Photo Credit: VersaBuilt

Workflow Changes

Like any shop, Rekluse was trying to make as many parts as possible, as fast as possible. Still, it had to walk a fine line between optimizing its workflow to improve process time without upending the entire process, which aims to have more uptime with less labor to meet the shop’s increased demand in its busy months.

Brown says this made it important for the company to look at its process from a holistic standpoint and remember that the machine cutting the part is only one aspect.While cutting the part is an important part of the process, Brown adds that it’s just one element of the process. To look at total process optimization from a holistic view, he suggests considering how much to optimize the total process versus one aspect of it.

For the high-mix, low-volume work at Rekluse, Brown says flexibility is a more important factor than trying to overly optimize a one-off process. An example he gives is reducing a 30-minute process down to 20 minutes. It could be possible, but it might negatively affect the stability and repeatability of that process by leading to situations like tool breakage, which could impact the uptime goal, especially if it happens at night during unattended machining hours.

Both the VBX-160 and Mill Automation System are designed to automatically load and unload parts for processing in a CNC machine, making them ideal for a lights-out machining setup. Photo Credit: VersaBuilt

Learning the Automation Software

To run an automation solution, users need to learn how to use the software. Havey says the software solution offered by VersaBuilt is parametric, meaning it’s similar to filling out a form: users enter the part, the number of operations for the part and the G code for those operations. Brown says this setup allows anyone who can run a CNC machine to easily learn and use the software with very little additional training. The software will then keep track of how many parts have been completed and how many parts are left to complete. This is all done while maintaining the flexibility to manage Rekluse’s high-mix, low-volume workload. Once a part is introduced, the software stores that part information, there is no need to reintroduce/reprogram a part, and there is no limit to the number of parts an operator can add to the system. To introduce a new part to one of the VersaBuilt automation systems, the only requirement is cutting a set of jaws.

“That’s what I need my customers to know how to do, is make their parts,” Havey says. “And if they know how to make their parts, which they typically do, we can absolutely help them automate those parts. And one of the ways we’ve done that is by taking this parametric approach to the software.”

VersaBuilt has kept this same approach with its latest product, the Mill Automation System, which uses the same software to automate a CNC mill in high-mix environments. It has been a long road, but with new lines of automation solutions out at VersaBuilt and what Brown calls a calm, “steady Eddie” shopfloor at Rekluse, the shop has come a long way from its formerly frantic winter months.

“It’s definitely a journey, right? And I think we were lucky because we had a lot of support from (Youngwerth),” Brown says. “That’s basically like, ‘Hey, we’re going to push this through.’ And where some businesses might have an opportunity to be like, oh man, I don’t know if we can realize all of this, we had kind of made the decision and went for it.

“And I guess that’s the thing that kind of came out of this journey was, it’s going to be impactful.”

Related Content

Using the Toolchanger to Automate Production

Taking advantage of a feature that’s already on the machine tool, Lang’s Haubex system uses the toolchanger to move and store parts, making it an easy-to-use and cost-effective automation solution.

Read MoreLean Approach to Automated Machine Tending Delivers Quicker Paths to Success

Almost any shop can automate at least some of its production, even in low-volume, high-mix applications. The key to getting started is finding the simplest solutions that fit your requirements. It helps to work with an automation partner that understands your needs.

Read More3 Ways Artificial Intelligence Will Revolutionize Machine Shops

AI will become a tool to increase productivity in the same way that robotics has.

Read MoreIncreasing Productivity with Digitalization and AI

Job shops are implementing automation and digitalization into workflows to eliminate set up time and increase repeatability in production.

Read MoreRead Next

5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More

.png;maxWidth=150)

.jpg;maxWidth=300;quality=90)