Solve Worker Shortages With ACE Workforce Development

The America’s Cutting Edge (ACE) program is addressing the current shortage in trained and available workers by offering no-cost online and in-person training opportunities in CNC machining and metrology.

Share

America’s Cutting Edge (ACE) is a national initiative for machine tool technology development and advancement supported by the Department of Defense Industrial Base Analysis and Sustainment (IBAS) program from the Innovation Capability and Modernization (ICAM) office. ACE is based at the Oak Ridge National Laboratory (ORNL) Manufacturing Demonstration Facility (MDF), a Department of Energy user facility for developing and validating systems and processes to support manufacturing innovation. The ACE workforce development activities are managed by IACMI – The Composites Institute.

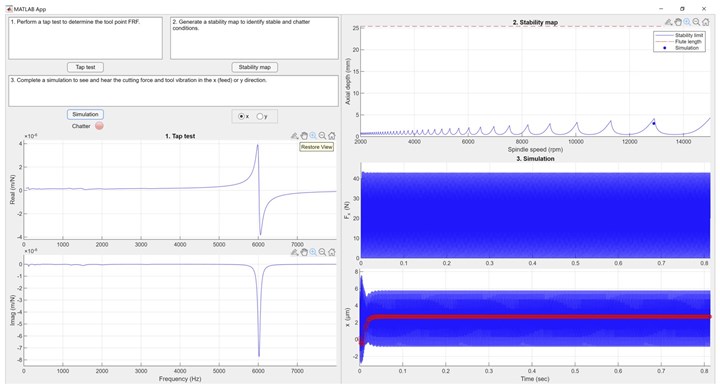

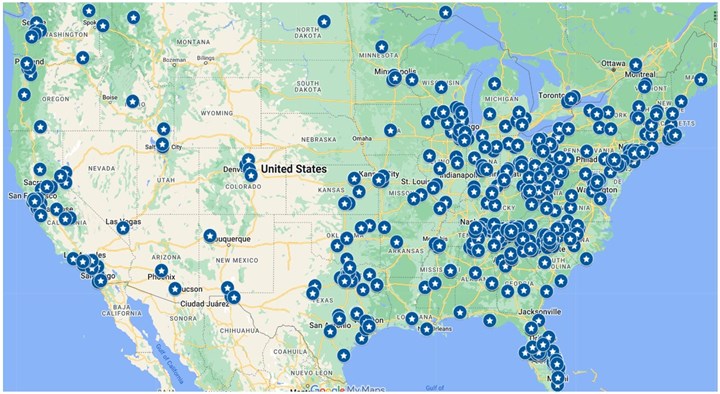

Developed at the University of Tennessee, Knoxville, the ACE CNC machining online component includes an introduction to machining, CAM instruction for toolpath generation, an introduction to machining dynamics, additional CAM instruction using CAM+ (an app that is included with the program and simulates machining force and vibration; see Figure 1) and an introduction to machining cost. Since December 2020, 4,600 participants have registered from all 50 states. This includes 73% who are currently students (high school, two-year colleges or four-year universities) and 27% from industry. Females make up 13% of the total registration. The participant locations are displayed in Figure 2.

Figure 1. CAM+ app used for online machining simulation. It plays the sound for stable and unstable (chatter) cutting conditions to mimic an on-machine experience. All figures provided by Tony Schmitz.

The ACE metrology online training, also developed at the University of Tennessee, Knoxville, includes an introduction to manufacturing measurements and an introduction to measurement uncertainty. Since March 2021, 900 participants have registered from 43 states. This includes 68% who are currently students and 32% from industry. Females again make up 13% of the total registration. The participant locations shown in Figure 3 are similar to the CNC machining participant locations from Figure 2. Both the CNC machining and metrology programs may be accessed at no-cost by registering at AmericasCuttingEdge.org.

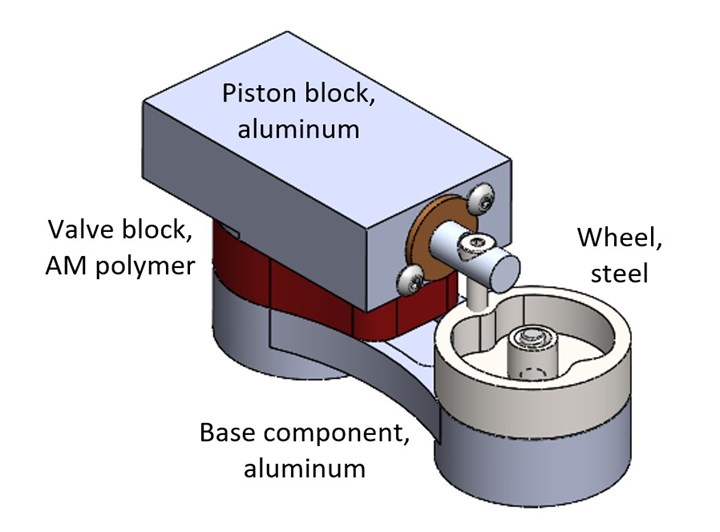

Participants that complete the CNC machining online training are eligible for no-cost, in-person training. The in-person training is instructor led, completed over five days (8:30 am to 4:30 pm), and limited to 10 participants per session. Participants machine four components for an oscillating piston air engine and assemble those components to produce a functioning engine at the end of the week (see Figure 4). Monday’s activities include a machining review, an M/G code introduction, and machining the air engine base. Tuesday’s activities include a machining dynamics review, a discussion of workholding and datums and machining the piston block. Wednesday’s activities include a review of machining cost, machining the mating surfaces for the additively manufactured valve block and machining a cross hole in the piston. On Thursday, participants receive a metrology review, machine the wheel and assemble their air engines for the first time (fasteners and bushings are provided). Friday’s activities include a CAM+ review, an on-machine tap test and chatter demonstration in collaboration with MSC Industrial Supply Co., logo machining on the piston block and an air engine assembly competition.

In-person training locations include the University of Tennessee, Knoxville, the ORNL MDF, Pellissippi State Community College, Roane State Community College, North Carolina State A&T State University, Marshall University, Texas A&M University, the University of North Texas, the University of Florida and others, with plans for additional locations. ACE certificates are awarded upon completion of both the online and in-person training.

Related Content

In Moldmaking, Mantle Process Addresses Lead Time and Talent Pool

A new process delivered through what looks like a standard machining center promises to streamline machining of injection mold cores and cavities and even answer the declining availability of toolmakers.

Read MoreInside Machineosaurus: Unique Job Shop with Dinosaur-Named CNC Machines, Four-Day Workweek & High-Precision Machining

Take a tour of Machineosaurus, a Massachusetts machine shop where every CNC machine is named after a dinosaur!

Read MoreBuilding Machines and Apprenticeships In-House: 5-Axis Live

Universal machines were the main draw of Grob’s 5-Axis Live — though the company’s apprenticeship and support proved equally impressive.

Read MoreManufacturing Madness: Colleges Vie for Machining Title (Includes Video)

The first annual SEC Machining Competition highlighted students studying for careers in machining, as well as the need to rebuild a domestic manufacturing workforce.

Read MoreRead Next

Setting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More