Quality Control Process Improved with Real-Time Data Collection, Analysis

Pinnacle Machine Works uses Mitutoyo’s MeasurLink data collection and SPC software to make the QC process more efficient and accurate.

Share

In late 2017, Pinnacle Machine Works embarked on a mission to transform and improve productivity as the company grew. This involved a reorganization of the manufacturing plant, the rollout of lean initiatives and an investment in new tooling. As this transformation progressed, additional opportunities for improvement came into view. In particular, it became clear that focusing on inspection alone would not be enough to improve the overall quality of the company’s products.

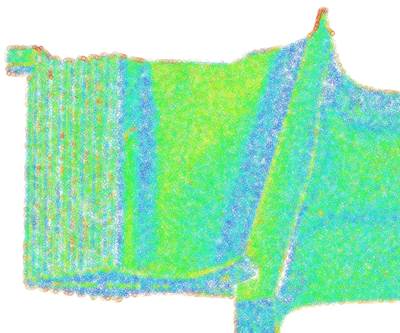

The internal diameter of a pipe is checked to determine if it’s within specification using a Mitutoyo indicator, while the data is displayed in real time on a monitor on the shop floor. Data displayed in real time enables better, faster quality control on the manufacturing floor.

Pinnacle manufactures oilfield couplings ranging in size from 4.5 to 10.625 inches and provides threading services of full-length pipe in the same size ranges. Established in 2013, the company has more than 100 employees and is housed within a state-of-the-art facility located in Houston, Texas, that is licensed with American Petroleum Institute (API) 5CT (casing and tubing specification) and API Q1 (quality management) standards.

Every product made at the facility was being inspected dimensionally and visually, resulting in thousands of inspection points per day. The traditional quality control (QC) method of writing measurements down was too slow to realize any potential manufacturing gains. However, the fact that more costly measuring equipment was not going to solve the issue prompted Pinnacle to investigate new QC options.

The Move to Real-Time Data Collection

In reviewing options related to improving and streamlining QC processes, Pinnacle realized it could either go the manual route and add additional QC personnel, or it could go the digital route and invest in an electronic gaging solution. The company decided that switching to an electronic gage was the logical choice. It would enable Pinnacle to maintain an accurate and increased product flow without increasing labor costs. In addition, it would allow for real-time data collection and the use of statistical process control (SPC), which up to this point had not been possible. Using data would help the company make serious improvements to its manufacturing process that, in turn, would improve quality.

The outer diameter of a pipe is measured using a Mitutoyo Digimatic indicator connected to a Miitutoyo U-Wave transmitter. The U-Wave sends measurement data to a PC where Mitutoyo’s MeasurLink collects and unifies data for analysis in a lab or in real time.

When selecting the data management solution that best fit its needs, Pinnacle considered a number of criteria:

- The ability to use traditional gages and techniques called out by API 5B (the specification for threading, gaging and inspection of casing, tubing and line pipe threads);

- The ability to capture inspection values in the software and store them by date, work order, machining center or other category; and

- the ability to report on and analyze inspection field data to uncover trends and determine better control measures.

Mitutoyo’s MeasurLink quality management software turned out to be the product that fulfilled the company’s criteria and aligned with its future goals. Combined with a multi-user relational database, MeasurLink is designed to deliver a safe and organized data warehousing system that makes quality data available for viewing and analysis by any member of the production, engineering or managerial staff. Inspection on the shop floor produces data for analysis, corrective action and various reporting needs. As the backbone of quality efforts, MeasurLink can be used to reduce production and quality costs and increase the bottom line.

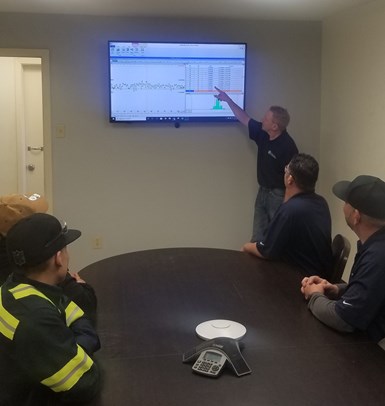

“We knew MeasurLink was the right choice for Pinnacle after looking at several other QC data collection options,” says Jim Caldwell, general manager. “It was one of the few options that had the power to provide us with real-time data and analysis.”

More Than a QC Tool

MeasurLink has now been used on the coupling shop floor for more than a year, with full implementation occurring within the last six months. As a result of installing MeasurLink, Pinnacle has seen its reject rate drop from 3 to 1.3%. At the same time, overall shop productivity has increased by 45%. To date, reduction of non-conforming product instances has saved the company more than $180,000 in lost material alone.

Now that the software is in place, Pinnacle is beginning to utilize control (Cpk Ppk) measures/targets to better control the process. Run charts and control charts enable machine operators to visualize their work. According to the company, employees are benefiting from the improved accuracy and streamlined workflows.

MeasurLink displays measurement data for statistical process control (SPC), analyzing what-if scenarios with historical data and making Pinnacle’s quality control process more efficient and accurate.

Employees are also able to ascertain information easily about when and why a part goes out of specification, which enables the quality manager to use a Pareto chart and other quality tools to identify the best place to take actionable improvements. One unexpected benefit of rolling out MeasurLink has been the ability to reuse the data for production throughput and tracking.

Given the positive response to and added benefits of adopting MeasurLink, Pinnacle is now in the process of implementing it in its thread shop.

Find a Local Expert

In terms of advice Pinnacle would give to other organizations looking to upgrade their QC process in the same way, the company stresses the importance of having a local subject matter expert. According to the company, it’s vital to have someone who can walk step by step through the decision and implementation process, especially since rolling out a new solution is essentially a full-time job until it’s completely set up and functioning at the expected level.

Mr. Caldwell advises companies that are looking to streamline the QC process to look ahead to the finish line despite how cumbersome this type of implementation might be, since in the case of his shop the end result has far exceeded his expectations. “It is incredible to see all the gains that Pinnacle has made in terms of control of product and efficiency of operations in just under a year, and what’s more incredible is that we’ve realized a full return on capital investment in that same timeframe,” he says.

Related Content

Ballbar Testing Benefits Low-Volume Manufacturing

Thanks to ballbar testing with a Renishaw QC20-W, the Autodesk Technology Centers now have more confidence in their machine tools.

Read MoreProcess Control — Leveraging Machine Shop Connectivity in Real Time

Renishaw Central, the company’s new end-to-end process control software, offers a new methodology for producing families of parts through actionable data.

Read More4 Ways to Establish Machine Accuracy

Understanding all the things that contribute to a machine’s full potential accuracy will inform what to prioritize when fine-tuning the machine.

Read MoreTurning Fixed-Body Plug Gages Inside Out

Fixed-body mechanical plug gages provide fast, high-performance measurement for tight-tolerance holes.

Read MoreRead Next

In a Machine Shop, the Labor of Lean is Data-Driven

Approximating single-piece flow in a job shop environment requires an ongoing commitment to analyzing and acting on evidence.

Read MoreTraceability Without Serial Numbers: Vision Technology Makes Every Part Its Own Identifier

Off-the-shelf imaging technology is now so good it can pick up the distinct surface features of seemingly identical parts. This startup company’s technology leverages what cell phones and other imaging devices can now do, identifying parts by their own unique features so that no serial number is needed.

Read MoreTaking A Reading on Gages

Are we taking advantage of the vast amounts of dimensional information that a gage or hand tool can produce? Certainly not if the information presented on the gage display reads only “over,” “under” or “good.”

Read More

.jpg;maxWidth=300;quality=90)