Articles

Real-Time Hob Monitoring

By obtaining the optimal signature for a hobbing operation, this continuous tool monitoring system protects hobs from unnecessary wear, and even failure.

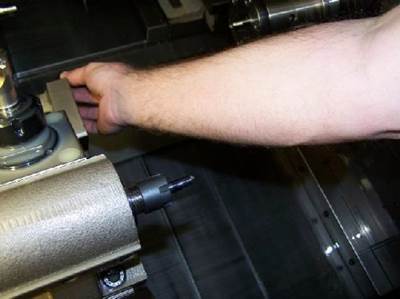

Read MoreSeeking Solutions for Cutting Tool Injuries

There’s more than one way for machinists to protect themselves when working inside CNC lathes.

Read MoreA Harder Surface for Stainless Steel

When it comes to hardening finished parts, the more control you have over the process, the better the results will be.

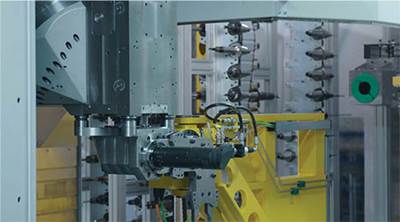

Read MoreTechnology for Turning on a Five-Axis Machine

A turning tool adapter that mounts to the MCT five-axis machine isolates the main spindle bearing from the shock of turning operations.

Read MoreSmart Shops Will Continue to Invest in New Technology

Although our latest survey shows that spending on machine tools will slow in 2016, it’s an “investor’s market” for metalworking companies with vision and boldness.

Read MoreReal-Time Tool Monitoring

Machine operators have long dreamt of a process monitoring system that detects tool wear, and potentially catastrophic conditions and automatically compensates for changes in tool geometry after resharpening. Now that dream is a reality.

Read MoreGears and the Future of Mobility

What will happen to things like step-gear transmissions as we transition to electrified vehicles? We go to Germany to find out.

Read MoreBearing Down on Industry 4.0

A research project in Europe is developing what could conceivably be the prototype for machine tools ideally suited for implementing data-driven manufacturing within the Industry 4.0 framework. One of the most interesting aspects of the project is embedding digital sensors in the bearing components inside the machine tool.

Read MoreAdditive Manufacturing’s Assist to ID Grinding

By addressing a long-standing coolant-delivery problem, an additively grown nozzle enhanced the effectiveness of ID grinding in a complementary role.

Read MoreShifting from Manual to Automatic

By partnering with its suppliers as a knowledge resource, this job shop made a successful transition from manual to CNC thread grinding, raising productivity and attracting new business with its increased capabilities.

Read MoreKnow Your Control

A new training center will enable Heidenhain to support its CNC users by ensuring that they are aware of all that the control can do. The value of some control capabilities don’t become apparent until they are seen in use.

Read MoreApprenticeship Model Expands in North Carolina

What’s good for the goose is good for the gander in this state, where established, European-style workforce development programs play a critical advisory role for brand new ones.

Read More