Articles

Retooling for More Effective Hard Milling

For Sarco Precision, Ingersoll's Hi-Feed Midi cutters solved problems with chatter and frequent tool breakage when milling hard materials on a 40-taper machine.

Read MoreRotary-Table Technology Improves Machining Repeatability

Pequot Tool & Manufacturing's imprecise rotary table positioning caused chatter and inaccurate machining. PL Lehmann's single-spindle rotary tables from Exsys/Eppinger provided repeatable rotary table positioning, consistent part tolerances and surface finishes.

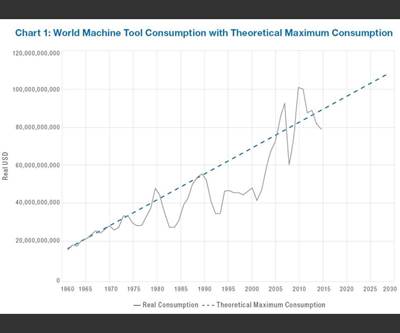

Read MoreUnderstanding the Machine Tool Industry’s Ups and Downs

In recent years, China’s patterns of consumption have had an exaggerated effect on global cycles.

Read MoreThe Key to Success with Flexible Machining Cells Is People

This aerospace component manufacturer is committed to flexible machining cells for producing complex parts for the latest commercial airliner programs. Its newest cell adds both capacity and capability—and takes the company to a new level of commitment.

Read MoreCoolant’s Impact on Face Milling Aluminum

Testing shows that understanding the interplay among cutting speed, tool wear and cutting power can lead to more informed evaluation of metalworking fluids and more predictable machining.

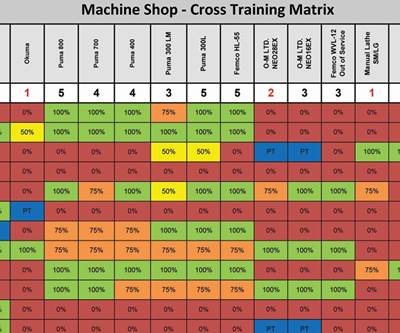

Read MoreIdentifying and Overcoming Skill Vulnerabilities in Staffing

This shop tracks cross-training as a performance metric. Management sees how many employees are fully capable of running each different type of machine tool. The data have helped the shop improve in this area, particularly since employees see the very same data as well.

Read MoreHighlights from Hyundai Wia’s Technology Center

This builder’s machine tool offerings are remarkably diverse. Its technology center has a sample of these machines, ranging from a “commodity” VMC to a five-axis contouring machine, with models for multitasking, hard turning, mold making and production applications in between.

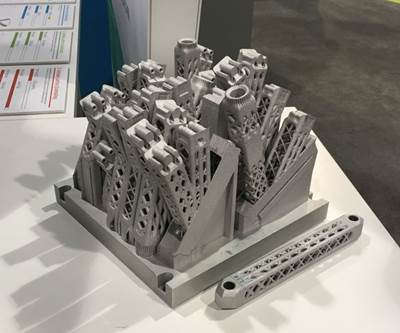

Read MoreAdditively Manufacturing a Large Component with a Small Work Envelope

Airbus successfully reduced the weight of an aircraft partition by redesigning it for additive manufacturing. The large component was produced in pieces, with connection features built-in.

Read MoreProducing Big Parts from Small Blanks Through Laser Cladding

The integration of laser-based additive manufacturing with WFL mill-turn machines is enabling the production of large parts in a single setup.

Read MoreManufacturing News of Note: April 2017

Sandvik Coromant opens a special automotive engineering project and training site, Stratasys launches an additive manufacturing consulting service, and other industry news.

Read MoreHigh-Productivity End Mills Made Possible Due to Tech of Penn Plant

Seco Tools cites the Stabilizer 2.0 end mill as an example of the type of product it is able to manufacture because of the grinding technology that has been part of the improvement of its Niagara Cutter facility.

WatchPenn State Prof. Timothy Simpson Joins MMS as New Additive Manufacturing Columnist

A monthly column will focus on concepts particular to AM, exploring the ways that this method of making parts is distinct from conventional processes.

Read More