Rotary-Table Technology Improves Machining Repeatability

Pequot Tool & Manufacturing's imprecise rotary table positioning caused chatter and inaccurate machining. PL Lehmann's single-spindle rotary tables from Exsys/Eppinger provided repeatable rotary table positioning, consistent part tolerances and surface finishes.

Share

ECi Software Solutions, Inc.

Featured Content

View More.png;maxWidth=45)

DMG MORI - Cincinnati

Featured Content

View More

Hwacheon Machinery America, Inc.

Featured Content

View MoreMike Goerges, sales and marketing manager for Pequot Tool & Manufacturing, says his shop’s goal has always been to exceed customer requirements. His father, mother and brother, along with one other employee, started the company in 1981 as a stamping and metal-fabrication operation. The Jenkins, Minnesota, shop has since expanded into precision machining, serving industries such as aerospace, medical, semiconductor, printing, electrical, hydraulic and industrial equipment.

Over the course of a month, Pequot can run between 600 and 800 active jobs with lot sizes ranging from a couple of parts to thousands of parts. Recently, though, the shop was experiencing poor part surface finishes and inconsistent tolerances on VMCs with rotary tables to enable four-axis machining, two problems that would randomly and inexplicably occur from one batch of parts to the next and sometimes even during the same part run. Pequot would set up a job and run some parts that would be machined to specification. Then, out of the blue, a part would come off the machine out of tolerance or with chatter marks on its surface finish, and tool life would suddenly take a nosedive.

In other instances, the machining process and part would appear fine until the shop measured the part on a coordinate measuring machine (CMM) and discovered that one of the its features was significantly out of tolerance. Then, the chase would be on again to track down the cause. Unfortunately, that meant the machining center in question sat idle while the problem was being diagnosed.

Pequot evaluated all aspects of its process to determine the cause of these problems, including the machine tools, toolholders, cutting tools, workholding devices and part programs. Eventually, the shop realized inconsistent rotary table positioning was the culprit, even though initial inspections of those tables seemed to reveal they were operating properly.

“The inconsistency hindered us from immediately tracing the cause back to the rotary tables,” explains Kevin Spielman, Pequot’s production manager. “When experiencing such a hiccup, we would adjust machining speeds and feeds to compensate, and get a few good parts. Then, unbeknownst to us, the tables would operate correctly, but we’d be running at the wrong machining parameters. This, in turn, also produced bad parts. After a while, we were constantly chasing our tails and second-guessing ourselves when it came to adjusting operational parameters.”

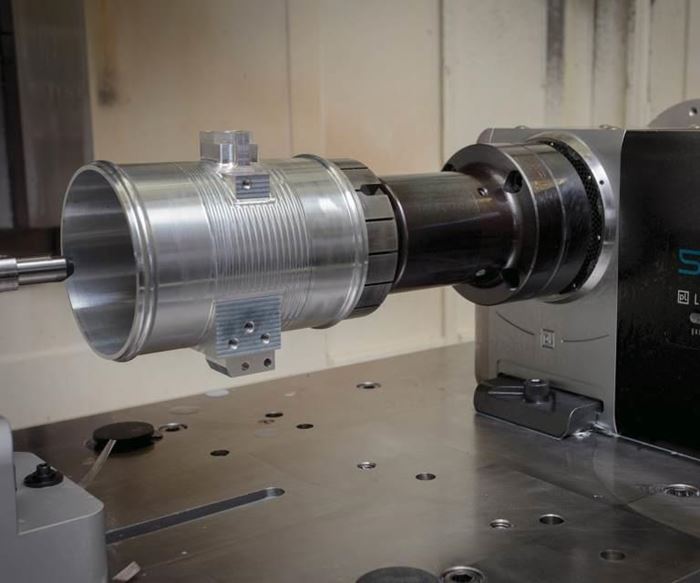

This spurred the shop to replace the tables with pL Lehmann EA510 and EA511 single-spindle units from Exsys/Eppinger. These rotary tables, acquired from local Exsys distributor Hill Industrial Tools, give the shop’s three-axis VMCs more reliable fourth-axis capabilities for part positioning and rotational machining.

“Once we installed the pL Lehmann tables, our inconsistency and rigidity problems vanished,” Mr. Spielman says. “We experienced immediate and further improvements in accuracy, tool life, machining speeds and material removal rates to the point that we reduced part machining cycle times by 25 percent. Plus, we basically eliminated any machine downtime associated with our previous rotary tables. Most importantly, the new tables have increased our machine utilization. We now have the confidence and ability to run our automated milling machines nonstop for lights-out production over night and on weekends.”

Despite their compact design, the pL Lehmann tables are said to offer strong resistance to pullout torque and axial force while providing high levels of clamping torque. In addition, their backlash-free, preloaded gear drive (PGD) technology is said to deliver the high torque common to gear-driven tables and the high rotational speeds common to direct-drive tables, with spindles capable of speeds ranging from 47 to 111 rpm and 90-degree moves in 0.34 second.

The spindles on the standard-model tables are guaranteed to within 5 microns of runout (less than 3 microns for the high-accuracy models). The tables’ ±1 arc-second positioning capability, along with near-zero runout, makes them well-suited for Pequot’s demanding tight-tolerance applications. Steel parts machined on the pL Lehmann tables typically measure approximately 1.125 inches in diameter and 8 inches long; aluminum parts are commonly 5 inches in diameter and 6 inches long.

Mr. Goerges says that with the increasing business Pequot is winning, its goal is to get the most production out of its manufacturing equipment. Automation plays a key role. In fact, the shop refers to this goal as “168,” referring to the number of available hours in one work week. “With the new rotary tables, we’ve increased our machine output and won back massive amounts of production time on our automated VMCs,” he says.

Related Content

Custom Workholding Principles to Live By

Workholding solutions can take on infinite forms and all would be correct to some degree. Follow these tips to help optimize custom workholding solutions.

Read MoreRail Manufacturer Moves Full Steam Ahead with Safe, Efficient Workholding Solution

All World Machinery Supply paired a hydraulic power unit with remote operating capabilities in a custom workholding system for Ahaus Tool & Engineering.

Read MoreCustom Workholding Shaves Days From Medical Part Setup Times

Custom workholding enabled Resolve Surgical Technologies to place all sizes of one trauma part onto a single machine — and cut days from the setup times.

Read MoreUsing Jaws as Grippers Enables Flexible, Low-Cost Automation

VersaBuilt’s automation systems significantly boosted Innovative Fabrication’s revenue. In return, the shop has helped VersaBuilt optimize its products.

Read MoreRead Next

Building Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More