The Key to Success with Flexible Machining Cells Is People

This aerospace component manufacturer is committed to flexible machining cells for producing complex parts for the latest commercial airliner programs. Its newest cell adds both capacity and capability—and takes the company to a new level of commitment.

Share

“We absolutely believe in cellular machining. It’s the only way to go,” Brad Stuczynski declares as he begins to explain the overall production philosophy that he and Brent Barker follow at Global Machine Works (GMW) in Arlington, Washington. These two are co-founders and co-owners of this company, which manufactures aerospace components, most of them for commercial aircraft. Boeing is their largest customer.

However, as soon as Mr. Stuczynski asserts the importance of machining cells at GMW, he is quick to state another core belief underlying the shop’s approach to aerospace production. “You absolutely have to have a top-notch workforce. The reputation of the people behind our technology is as big a factor in winning contracts as the capability of our cells, machine tools, programming systems, inspection equipment and assembly operations,” he says.

GMW’s newest machining cell reflects this emphasis on cellular technology as well as the emphasis on workforce talent. Many of the benefits of this cell can be traced to particular features or functions of the machine tools and the integrated pallet system that links them, but in almost every case, there is something that operators, programmers, engineers or other staff people have contributed in order for that feature or function to add maximum value. Without the contribution of these skilled individuals and their ability to work as a cohesive team, Mr. Stuczynski believes that GMW would have missed realizing the full potential of the cell as a highly efficient, productive asset.

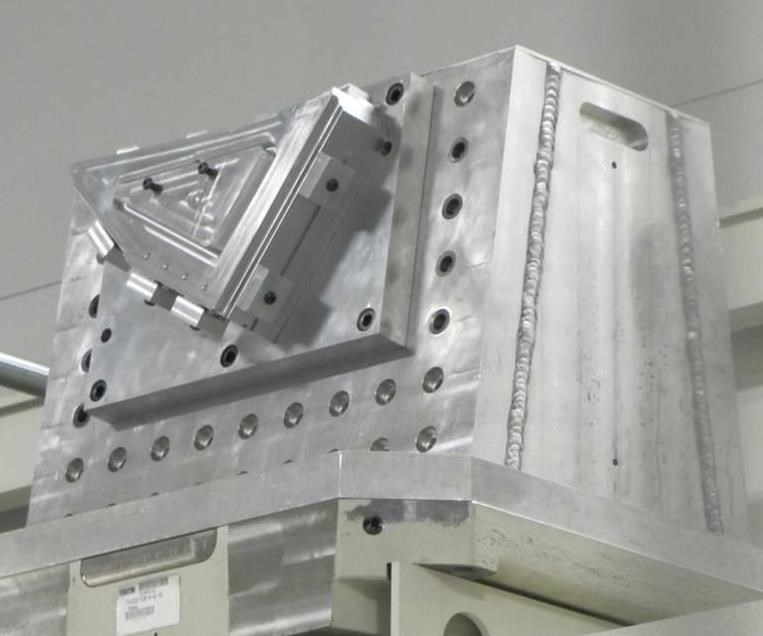

One example makes this point. The cell consists of three five-axis machining centers from GROB. These machines have some unusual design features. To unlock the advantage of these design features, GMW developed its own modular fixturing system based on customized subplates. “Developing, implementing and managing this palletized fixturing system is the result of amazing teamwork at GMW. It’s what our workforce brought to the cell that makes it such a huge boost to our capabilities,” Mr. Barker explains.

The palletized fixtures enable the cell to run continuously 24 hours a day, four days a week. Two operators are on duty for back-to-back 10-hour shifts. The cell runs totally unattended the remaining four hours. The rest of the week, the cell runs continuously for one 12-hour shift each day with a single operator, and unattended in as many of the remaining hours as needed. Each machine is “in the cut” an average of 85 to 95 percent during run time, the owners say.

“It’s not just that these machines are almost always busy,” Mr. Stuczynski says. “They are busy making the largest and most complex workpieces produced by any cell in our shop.” These workpieces require five-axis capability, and few of the fixtured pallets do not use the entire work envelope. (“And that’s by design,” Mr. Barker adds.)

Many other aspects of the machines, the structure of the cell, its scheduling regimen and so on, add to the cell’s success. However, one theme consistently emerges in an examination of these various aspects: “It takes great machining technology plus great people to make outstanding parts,” Mr. Stuczynski says.

Of course, to builders of aircraft, “outstanding parts” are ones that meet every specification, arrive on time and offer the lowest cost. Being a reliable supplier of outstanding parts has made GMW one of the fastest growing aerospace suppliers for Boeing in the Northwest, the owners say. The shop has been awarded contracts for more than 300 new parts in the last nine months in support of Boeing’s 777X aircraft, they add. GMW is now a Tier-One supplier to Boeing.

In a Growth Mode

GMW was formed in 1998 as a small, subcontract machining operation representing a partnership between Mr. Stuczynski (president) and Mr. Barker (vice president). Mr. Stuczynski has a background in machining and shop management, including experience in milling, turning, grinding and CNC programming. Both had the opportunity to see the best and, in some cases, not quite the best in management practices. These were valuable lessons, they say.

For example, one thing they recognized is that managers must have multiple skills and abilities. (As a case in point, it doesn’t take long in a discussion with Mr. Stuczynski and Mr. Barker to recognize that they have strong business instincts as well as deep technical knowledge, plus what appears to be genuine humility—a rare combination of leadership qualities.) When managers can fulfill more than one function, a shop needs fewer managers. Mr. Stuczynski calls this “lean management.” Developing a diversity of management skills takes time, so he likes to point out that seven of GMW’s top managers each have at least 20 years of experience.

At its founding, GMW occupied one part of a building in an industrial park next to the county airport on Arlington’s north side. As the company grew steadily, it took over more buildings in the park as they became available. In 2015, it doubled the size of its largest building with new construction. Today, the company has around 100 employees and more than 54,000 square feet of manufacturing space. According to Mr. Stuczynski, GMW has seen business grow an average of 25 percent every year since 2011. The owners attribute this growth to two main factors—aggressively acquiring advanced machining technology and building a well-managed, motivated workforce.

The shop is equipped with turning centers, vertical and horizontal machining centers, and assembly facilities. A large portion of what GMW delivers to customers is shipped as complete assemblies and subassemblies.

The shop’s VMCs exist as stand-alone machining stations for simpler parts produced in low volume. However, all of the shop’s four-axis HMCs are incorporated into cells with in-line pallet-transfer systems. The first cell was installed in 2006 and has two HMCs with 24 pallets. The second cell was installed in 2012 and has three somewhat smaller HMCs and 48 pallets.

Experience with these cells confirmed the shop’s commitment to cellular production technology. The most important principles about cellular production have been applied and refined on them, the owners say. A few of these principles: assign one operator per shift, maximize the number of parts per pallet, minimize the number of tools for all the work on the cell, and run the cells continuously by keeping loaded pallets available at all times. But Mr. Stuczynski stresses that cellular production is the key to globally competitive pricing of components: “Cells virtually factor out the cost of labor, so you can focus on getting more and more efficiency out of the technology. That’s how you stay ahead in the business of supplying low-run, high-precision parts required by key customers.”

A Big Jump Up

In late 2013, Mr. Stuczynski and Mr. Barker saw the need for a cell that could produce parts larger than either of the two existing four-axis cells could handle. The new cell would also need simultaneous five-axis capability. Mr. Barker explains that aircraft designers today are creating larger parts that formerly consisted of four or five separate pieces. The complexity of these parts requires the maneuverability of five-axis cutting to reach otherwise difficult-to-access features. And most of these parts have surfaces requiring five-axis contouring. Ribs for leading edges of wings are perfect examples of large aircraft components calling for this level of machining capability. This was the kind of work that GMW was now after.

Five-axis capability also makes sense in a cellular context. It has the potential to complete a part in fewer setups, because five sides can be machined in one cycle. With the proper fixtures, parts on one pallet could represent a lot of machining time between pallet changes for high spindle utilization.

Even with this compelling rationale, however, Mr. Stuczynski and Mr. Barker saw this move to a cell with five-axis machines as a bold step with some real risks. “We knew there would be a learning curve, even with all of our experience with and commitment to flexible machining cells,” Mr. Stuczynski recalls. “Every principle we knew about running cells would have to be applied with more discipline, intensity and resolve.”

The search for suitable five-axis machines of the required size and capability eventually was narrowed down to Grob Systems, a German machine tool builder with U.S. headquarters in Bluffton, Ohio. Grob is best known for its machining applications in automotive, but has concentrated on general-purpose machining centers in recent years. In mid-2013, a buying team from GMW had a good look at Grob machines in Bluffton. It appeared that three Grob G550 universal machining centers married to a multi-level, in-line pallet system from Schuler, also based in Germany, would be the best choice.

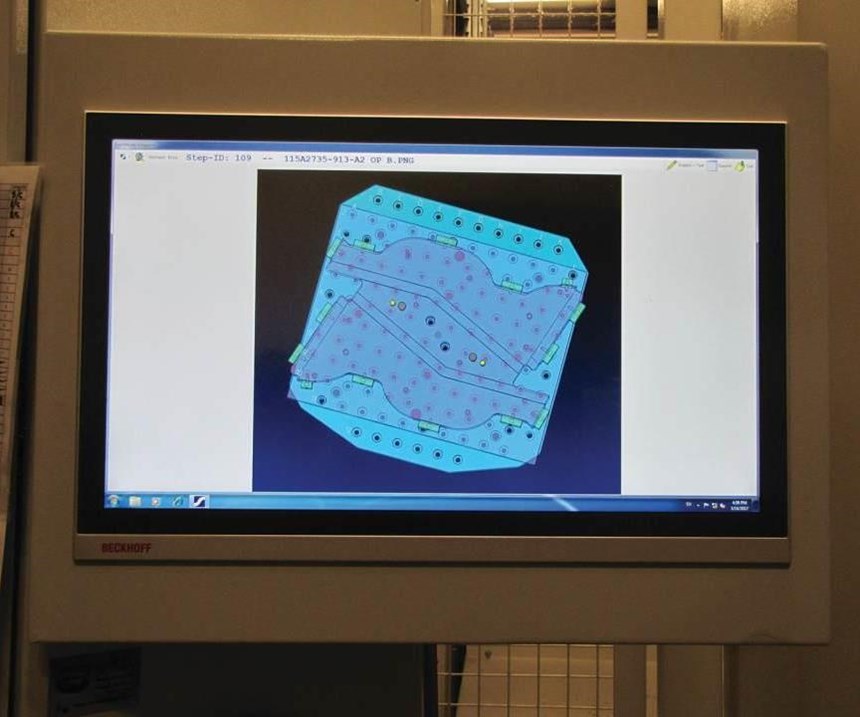

Several selling points about the G550s stood out. These included the one-sided trunnion design that enables highly flexible positioning of workpieces for maximum access to all five sides. When needed, the trunnion can swivel the worktable completely upside down to clear chips and coolant. The cutting spindle fully retracts from the cutting zone during positioning moves or during tool changes. This enables virtually the entire work envelope to be available for machining without restrictions due to clearance issues. A control unit with adequate memory and processing speed is available for data-intensive programs often comprised of 10,000 or more lines of code.

In addition, the machines are configured for ready incorporation into a cell. All maintenance points are located on one side, where they are accessible and logically laid out. Chip conveyors discharge from the rear with a chute over the main aisle of the cell. The overall footprint of the machine is compact, a concession to the tight quarters frequently found in automotive plants.

In early 2014, GMW placed the order for three machines. Two were installed with the entire pallet system later that year. The third machine arrived early in 2015 to complete the cell.

The G550s are universal-style machines with 43-hp, 16,000 rpm spindles. When the trunnion holds the worktable horizontally, the machine operates as an HMC. When the trunnion moves to orient the worktable vertically, the machine operates as a VMC. Because the swivel and rotation of the trunnion can be programmed to move in conjunction with the feed of the cutting spindle, five-axis simultaneous contouring is possible (and this is the most common mode for these machines, Mr. Stuczynski says). Each machine has a 120-pocket automatic tool changer for HSK-style tooling. The machining zone is 31.4 inches in X, 40.1 inches in Y and 40.1 inches in Z.

Learning Together

GMW learned substantial lessons from its initial experience with this five-axis cell. Mr. Stuczynski and Mr. Barker summarize the insights and truths they garnered here:

- Complexity goes up considerably with five-axis operation compared to four-axis. Fixturing, tooling and programming all become more demanding and “touchy.” Small details left unnoticed can cause big headaches.

- Five-axis machines are significantly more expensive to own. Mr. Stuczynski says the short-term ROI numbers are “certainly adequate,” but long-term value is in the growth potential for future contracts. Faith in the future has to supersede the balance sheet figures, he says.

- Five-axis machines need more support from every department that gets involved, including maintenance, programming, engineering

and scheduling. - Programming costs for five-axis work can be triple those for machines with fewer axes. Five-axis CNC programs require higher programming skills, more powerful CAM software and longer prep time, plus closer review with simulation and collision testing.

- Operators have to be particularly alert, proactive and attentive to detail. Experience counts. Training is essential.

- Upfront planning is critical and can be extensive. “We did our homework,” Mr. Barker says. For example, engineering and making the fixtures was a major project, but these early efforts paid big dividends in terms of fewer overall setups and minimal refixturing requirements.

For its part as the machine builder and system supplier, Grob seems to have learned a lot, too, Mr. Stuczynski says. Aerospace work is markedly different than automotive, for example. Aerospace involves hogging a large quantity of material from solid billets. Very few of GMW’s parts start out as castings or forgings, which are common in automotive production. Aerospace work makes a lot of chips. A high volume of coolant that is clean and chilled is needed. In aerospace, each machine may touch a dozen different parts in each shift. Tools are changed frequently. Getting cutters in and out quickly is required to shorten cycle times significantly. Many different tools will be required.

Mr. Stuczynski reports that Grob addressed these issues promptly and thoroughly. “Their sales engineers and service technicians have an automotive, make-it-happen, do it-it-now mindset that works well for aerospace,” he says.

The one hitch that GMW notes was getting all the software features in the CNCs and pallet system controller installed and working smoothly. “We had some issues with interfaces to the pallet changer and some bugs with the postprocessor, but these were worked out satisfactorily once Grob and Schuler understood exactly what we wanted and needed to do,” Mr. Stuczynski says. Grob now offers a software package incorporating the software features and functions an aerospace shop would find attractive.

In this kind of application, Grob recommends the Siemens 840-D control on its strength in handling very large programs, which, along with large memory and high processing speeds for program execution, are required.

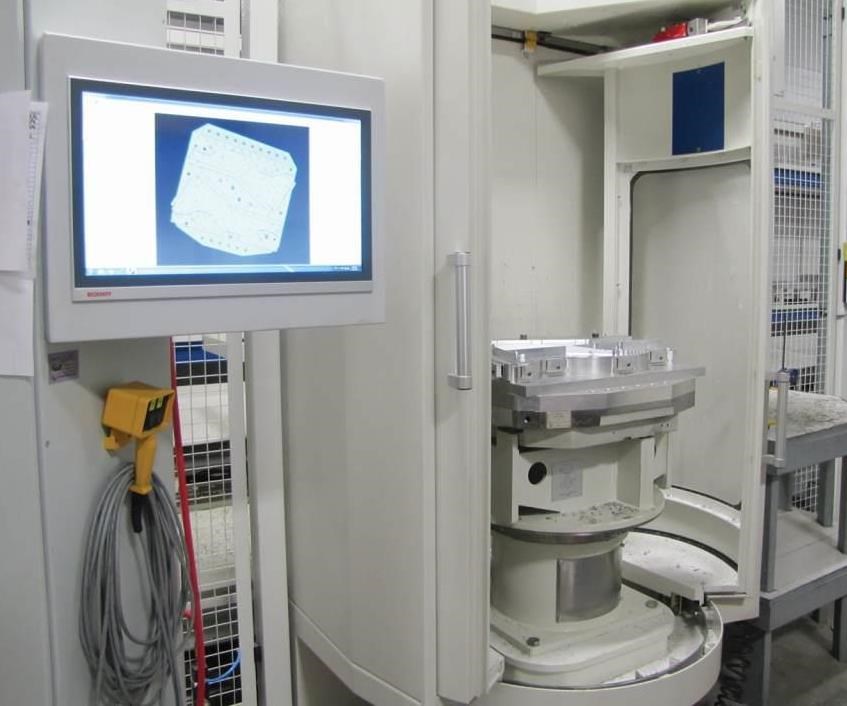

Machines + Pallet System = Cell

What makes the three G550s a cell is that they are connected to and linked by the Schuler pallet system. Each machine has a single-station pallet changer that enables one pallet to be in the workzone for machining while the other pallet is available to the rail-mounted robot. The robot has two pallet forks that enable it to remove the pallet at the machine with one fork and then immediately rotate to load the pallet on the other fork. The robot can then take the pallet fresh off the machine and bring it to the load/unload station or place it in one of the empty stations on the bi-level storage racks. Typically, the robot then retrieves the pallet that is scheduled to load at the next available machine.

By continuously and quickly exchanging pallets, the machines never wait longer than a few minutes for new workpieces before they start cutting. All operations of the pallet system are automated and managed by the computerized cell controller. When a pallet with finished or partially finished workpieces is delivered to the load/unload station, the cell operator can remove the finished pieces or flip the partially finished ones for further processing.

The system is entirely enclosed for safety, but access doors with safety interlocks are located at each end. Each machine has a side entrance for access to the workzone. When it is open, the machine is locked out, but the other two machines and robot remain in operation.

These design features point to the inherent productivity of a flexible machining cell. However, Mr. Stuczynski notes that the overall productivity of this cell is also influenced by several factors under the shop’s control. These factors include fixture design, cutting tool selection, part process plans, toolpath efficiency and more. This means that an identical cell installed elsewhere might be more or less productive, depending on how well these factors are managed. “It’s up to us to get the most out of the cell’s potential. If another shop had a cell exactly like this one and was getting the same 85- to 90-percent spindle utilization as we are, we could still be able to out-produce that cell with ours,” he claims. “We simply have to have a smarter production strategy.”

Mr. Stuczynski and Mr. Barker are very open about the broad outline of this “smarter” production strategy. This outline can be split into two main topics: fixturing for the pallets and a set of operational rules the cell adheres to.

Effective, Flexible Fixturing

The basic workholding components for this cell are the 32 pallets that fill the 32 stations on the pallet system. GMW designed and produced its own modular fixturing system to mount on the pallets.

“Our engineers came up with an array of precision mounting bores that are threaded to receive locating/clamping pins,” Mr. Barker explains. These threaded bores and pins enable subplates to be mounted to the pallet while maintaining a consistent location and orientation that is repeatable within a few microns across all 32 pallets. Part-specific clamping and locating fixtures are then semi-permanently attached to the subplate.

GMW has developed a unique fixture design for every part number that is produced on the cell. If batch sizes and frequency of repeat jobs warrant it, a few fixtures have been replicated on multiple subplates. All subplates and associated mounting fixtures are produced in the shop’s capable and well-equipped tool room, Mr. Stuczynski says. Subplates with attached fixtures are stored on shelving near the cell when not active.

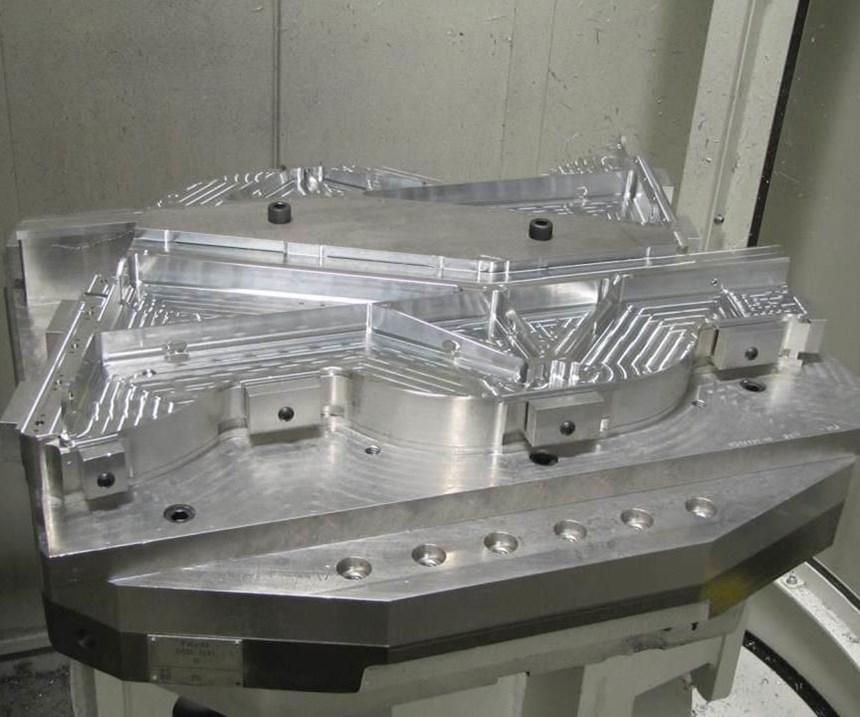

Currently, the bulk of the jobs produced on the cell are ribs for the leading edges of B777 main wings and B787 ribs for trailing-edge ailerons and hinge covers. These are large families of similar parts, so many of the fixtures look alike.

“We design fixtures to hold as many parts as can fit inside the workzone on this cell’s machining centers. The one-sided trunnion and fully retractable tooling spindle are advantages here,” Mr. Stuczynski explains. Fixture designers have freedom to be creative, he says. He points to one style of fixture that resembles a large slope-sided toaster. This design enables two parts to be loaded as if leaning against one another. Doubling parts in this manner helps reduce pallet changes and keeps the machines in the cut longer.

“Our goal with smaller parts is to have fixture designs that can load enough parts for at least one hour of machining time per pallet,” Mr. Stuczynski says. He says the larger parts produced on the cell start as a 23-by-27-by-5-inch billet and require 2.5 hours for roughing and finishing.

Fixture design also impacts cutting tool requirements. “We look for opportunities to position a workpiece at a certain angle in the fixture so a standard cutting tool rather than a special or custom tool can reach a surface to machine a feature or drill a hole,” Mr. Stuczynski says.

Rules of Engagement

In addition to gains from fixture design, productivity of the new cell is enhanced by following a set of rules or principles for operation. One of the main benefits is dynamic scheduling, whereby the system can “reshuffle” the lineup of scheduled pallet changes if order quantity or priorities change, customer emergencies arise, or other contingencies emerge.

- Strictly maintain the interchangeability of all three machines. This rule ensures that the same results are obtained regardless of which machine a pallet is directed to. Machines undergo a monthly recalibration of kinematic performance so automatic compensation tables can be updated. Each machine is checked for volumetric accuracy, and all three machines must meet the same standard of accuracy throughout the entire work envelope.

- Strictly maintain identical tooling in all three ATCs. Programmers must stay within a library of tool types in which basic, short-style tools are preferred. Some specials or custom tools such as angle heads and tapered ball mills are in the mix when justified, because they eliminate an operation, avoid an additional setup or take advantage of the machine’s five-axis maneuverability.

- Maximize “unattended” operation. Dan Cardiff, the cell manager, explains that the main task of the operator on duty is not running the cell, but rather preparing what is needed to keep it running automatically. This involves making sure cutting tools, fixtures, incoming billets and outgoing finished parts, and so on are taken care of. “We expect three hours of production for every hour of operator time. Sticking to this ratio optimizes cell output,” he says. He clarifies that, while labor input may be a minor factor in production costs, the operator’s vigilance, diligence and intelligence are critical.

Stay in Formation

GMW’s commitment to cellular manufacturing is an active force that is propelling the company into the future, Mr. Stuczynski says. As proof, he points to the next flexible machining cell that is now under construction. The first HMC for this cell was placed on the floor in September 2016. It can handle even larger workpieces than the G550s and has five-axis capability as well. This cell will share space in the company’s newly expanded building, which also houses the growing assembly operations.

Mr. Stuczynski sums up his outlook by simply saying, “Our customers don’t stand still, so neither do we.”

Related Content

How to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

Read MoreHow to Successfully Adopt Five-Axis Machining

While there are many changes to adopt when moving to five-axis, they all compliment the overall goal of better parts through less operations.

Read MoreBallbar Testing Benefits Low-Volume Manufacturing

Thanks to ballbar testing with a Renishaw QC20-W, the Autodesk Technology Centers now have more confidence in their machine tools.

Read MoreHow to Determine the Currently Active Work Offset Number

Determining the currently active work offset number is practical when the program zero point is changing between workpieces in a production run.

Read MoreRead Next

5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More