Articles

HMC Skiving Consolidates Gear Machining

A rigid machine platform and the right CNC promise to reduce stackup error and cycle times for both established gear-making operations and new players.

Read MoreVideo: Building Your Business Through Benchmarking

Learn how this shop leverages the Top Shops program to build its business, boost company morale and better direct its improvement efforts.

WatchDigital Resource: Finding and Learning About Cutting Tools

Two features stand out on Seco Tools’ new website: a utility named “Suggest,” which calls up detailed tooling recommendations depending on the application, and a “News and Events” feature that consists of readable discussions of new and basic tooling concepts.

Read MoreRetired Machinists in a Contingency Staffing Role?

Temporary hiring of retired machinists can enable shops to quickly and easily change capacity when business ebbs and flows.

Read MoreLean Manufacturing Begins With Layout, Commitment

Sustainably streamlining production of a varied mix of low-volume work depends not only on a strategy tailored for job shops, but also on human drive and enthusiasm.

Read MoreShrinking Costs: The Tool Life and Cycle Time Advantages of Shrink-Fit Tooling

A Tier-One automotive supplier measures the value of a toolholder change.

Read MoreSkills Training Strengthens Shops, Communities

A poverty-fighting nonprofit serves regional manufacturers as both a pipeline of fresh recruits and an incubator of existing talent.

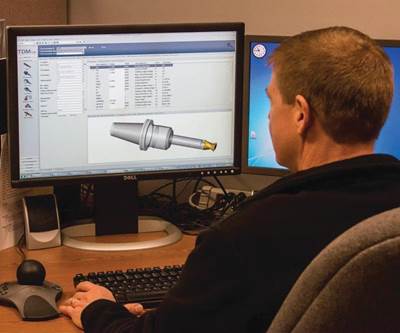

Read MoreCase Study: What Is the Cost of Lost Information?

Making sure all employees are using up-to-date information that is communicated effectively between departments helps save companies both time and money.

Read MoreHiring, Training and Supporting the Workforce in School and on the Job

Virginia’s Rolls-Royce Crosspointe plant shares its strategies for attracting, hiring and supporting its workers, while Danville Community College excels with its integrated machining education model.

Read MoreJenoptik Automotive Opens New Michigan Technology Campus

This 100,000-square-foot facility will be devoted to the production and testing of the company’s automated laser-cutting and gaging solutions for the North American automotive industry.

Read MoreVideo: Additive Manufacturing Is a Logistics Solution

UPS discusses its use of cloud-networked 3D printers to provide part-making near the point of end use.

Read MoreClosing the Loop on Data-Driven Manufacturing

Hexagon’s annual conference highlighted strides in expanding beyond metrology to smart factory connectivity.

Read More