Articles

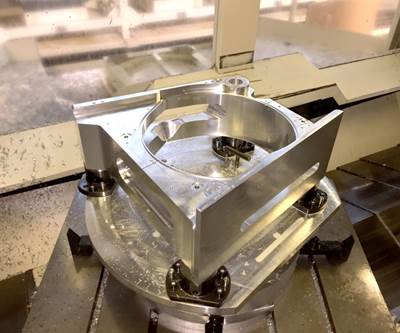

Workholding System Suits Five-Axis Machining by Clamping Underneath

The clearance is an added benefit of the quick-change system, potentially facilitating five-axis as an automation tool.

Read MoreThreading Options for Hard Materials

Here are three approaches to threading hardened components.

Read MoreWhy (and How) to Benchmark Your Machining Business

Doug Woods, president of AMT—The Association For Manufacturing Technology, shares the importance of benchmarking your manufacturing business and how the Top Shops program and conference can help.

WatchManufacturing News of Note: July 2017

A big R&D agreement looks at additive for structural airplane components, Autodesk appoints a new president and other industry news.

Read MoreSecond-Referencing Variables in Custom Macro

This technique allows operators to query a large number of values using only a few CNC commands.

Read MoreBeyond Just Hiring

This New Jersey shop sees employee training as fundamental to its success.

Read MoreSubmerged in Robotics

The new Denso IP67 submersible robot doesn’t mind a shower of metalworking coolant, which makes it ideal for tending CNC machines inside their enclosures. This capability was demoed during the company’s 50 years of robotics celebration its newest training center in West Chester, Ohio.

Read MoreCatch Up on PMTS 2017’s Live Demonstrations with This Video Playlist

Covering workholding, Swiss-type turning, multitasking machines and more, the seven talks in the YouTube playlist are a good recap of the latest in production machining technology.

Read MoreInventory: An Unseen Opportunity for Cutting Tool Cost Saving

Research finds cost saving is an expressed priority when it comes to cutting tools, but relatively few shops take steps aimed at reducing tool management’s contribution to overall cost.

Read MoreGardner Business Index: Metalworking June 2017 – 56.2

The metalworking industry is closing the gap between costs and prices.

Read More3D Printing for “Hybrid” Tooling

An aerospace contractor added a 3D printer to help make custom tooling. In many cases, this means combining printed and machined components.

Read MoreTurning Process Can Cut Cycle Times 50 Percent, or More

When Sandvik Coromant announced that its new PrimeTurning process could cut cycle times in half, some were skeptical.

Read More