Lean Manufacturing Begins With Layout, Commitment

Sustainably streamlining production of a varied mix of low-volume work depends not only on a strategy tailored for job shops, but also on human drive and enthusiasm.

Share

After enough one-size-fits-all initiatives, lean manufacturing can lose its luster. After all, the Toyota Production System (TPS) that forms much of the basis of modern lean thinking doesn’t apply perfectly to every manufacturing operation, particularly job shops.

And yet, the experience of at least one manufacturer shows that the perfect doesn’t have to be the enemy of the good for producers of high-mix, low-volume (HMLV) parts. For a little more than a year now, Wear Technology has been leveraging core lean principles to reorganize and improve operations at its 63,000-square-foot facility in McPherson, Kansas, where it manufactures and refurbishes hundreds of varieties of twin extrusion screws for its parent company, plastics processing equipment supplier Milacron LLC. Arguably as far removed from the Toyotas of the world as any job shop, this operation is a case in point as to why negative attitudes toward lean, however justified by past experience, can be misguided and unfortunate.

Although still in the first of three phases, this ongoing project has measurably and significantly reduced the distance products travel through the plant, the time employees spend on non-value-added tasks, and lead times quoted to customers. Chris Keating, plant manager, attributes much of this success to a tailored approach to lean, one that recognizes the need for flexibility and the fact that some measure of waste is likely inevitable in an HMLV facility.

Methodology aside, the primary drivers of lean change—the real heroes of Wear Technology’s story so far—are the people living and championing the ongoing transformation. The entire staff has been involved and engaged in the process from the outset, Mr. Keating says. The company has even gone so far as dedicating personnel specifically to the effort: three Wichita State University (WSU) graduate students who worked stints at the shop as part of their master’s degree programs in industrial engineering. One of those students, Sachin Varkey, has formally joined the engineering staff to continue spearheading the effort. More specifically, to help keep lean alive, not just in the form of continued layout and process changes, but in the minds of everyone those changes affect.

Focused on Flow

“Boots on the ground.” That’s how Mr. Varkey describes his role, and those of Vasudev Nalapat and Ramkumar Harikrishnakumar, when the three graduate students were first brought on board in early 2016. By that point, the shop had already been working with Shahrukh Irani, Ph.D., president of Houston, Texas-based consulting firm Lean and Flexible LLC and a specialist in job shop lean. However, both Dr. Irani and management needed eyes and ears on the floor that wouldn’t be distracted by the day-to-day urgencies of production. “Projects were all laid out for us,” Mr. Varkey recalls about the students’ first days at the plant. “Our job was to identify the limitations on those projects and gather the data to justify them.”

Incorporating elements of Theory of Constraints, group technology and production flow analysis, the chosen methodology, dubbed JobshopLean, focuses on a more specific goal than cost reduction through waste elimination. HMLV manufacturers need to specifically prioritize eliminating constraints on throughput—on the flow of work through the various processing stations. Otherwise, lean programs may well devolve into a series of what Dr. Irani calls “willy-nilly waste hunts and kaizens” with only limited impact on the metric that matters most: timely delivery to the customer.

First-in, first-out “pull” production is always the goal. However, this lean ideal can be elusive when assembly lines and single-piece flow cells are impractical. Extrusion screws are more varied than meets the eye, and few pairs are alike. Is this set parallel or conical? What’s the size? What is the curvature and pitch of the flights and the width of the channels? How do these and other specifications differ from section to section of the screw? Will the coating be tungsten or molybdenum? All these considerations and more determine which processing sequence a given pair of screws might require.

Barriers to flow extend beyond a mix of work that defies grouping into even loose part families. The manufacturing sequence for a typical screw involves more than 40 distinct steps, including “dirty,” manual operations like welding that can be difficult to integrate directly with CNC machining. Some workstations see the same screw more than once, some screws require specific equipment at certain stations, and processing times vary widely, both from station to station and from job to job at each station. Further complicating matters, used screws shipped in for refurbishing share most of the same processes in common with new ones. Stored on sawhorses after inspection, often for weeks at a time, these screws must be incorporated into the production schedule whenever the customer approves the work.

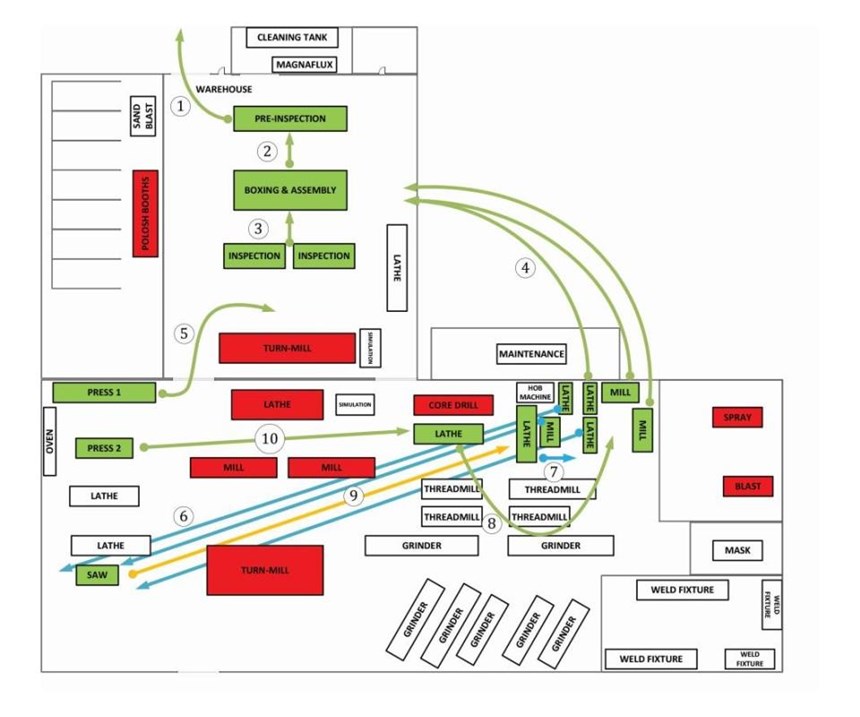

Wear Technology has no illusions about how close it can come to the assembly line ideal, but the shop presses ahead nonetheless. A central tenet of the chosen approach to lean is that there is a middle ground between self-contained, single-piece-flow manufacturing cells and inherently wasteful “process village” layouts, in which batches of work wind their way through departments of similar machinery in different areas of a facility. Wear Technology may still be a process village, but getting closer to this middle ground has reportedly reduced the average distance a pair of screws moves through the shop by approximately 20 percent. Meanwhile, process-specific improvements and creative workarounds to inherent layout limitations speed the screws’ travel along these newly shorter routings. Perhaps most notably of all, the shop’s journey has only just begun.

Little Pain, Plenty of Gain

The end game is ambitious. In addition to Dr. Irani, the shop has been leveraging the expertise of Mark Lonneman, global continuous improvement manager at Milacron and the primary overseer of lean reform and other process upgrades at all the company’s production facilities. For Wear Technology, significant capital expenditures are likely ahead, and there’s even the possibility of relocating processes like welding that require their own segregated infrastructure. However, these are long-term, tentative plans. Phase-one reform has been restricted to only low-cost, incremental change. Aside from the salaries of the students, the expense of the consulting, and some new hoists and other relatively inexpensive purchases, all efforts to improve flow—and by extension, eliminate waste and reduce lead time—have leveraged only existing resources.

“It’s like a game of checkers,” Mr. Varkey says, explaining the importance of ensuring each step supports the next while also leaving room to revise plans in the face of unforeseen barriers. For example, to support the goal of separating new and rebuild work, one of the first moves was shifting pre-inspection and storage of incoming used screws to the warehouse, away from the main facility. With that move established and 5S and other lean activities underway in that area, the newly vacated location became home to boxing resources, which, in turn, had been moved away from an area now occupied by the shipping table.

This chain of events freed enough floor space for a move that the students say has been particularly impactful on overall flow: moving a straightening press to an area immediately across from a massive Weingartner turn-mill with an 8-meter bed. A simulation station (a table with various tools for checking screws’ fit and function) is also located nearby. Tightly grouping these processes into a partial cell has streamlined production of larger screws that often require multiple trips between the turn-mill and straightener before simulation qualifies them to move onward.

Similar moves have occurred throughout the facility, all with the same underlying goals: to minimize material handling distance, to improve communication and, ultimately, to speed deliveries by locating the most common sequential operations as close together as possible. Carefully scheduled to avoid disrupting production, these layout changes have required little effort beyond planning and physically moving the equipment.

That is, when equipment can be moved in the first place. The fact that the Weingartner lent itself to being the anchor of a process grouping is fortuitous, because the machine is too large and heavy to relocate without disrupting production beyond phase-one comfort levels, the students say. Other machines, like some of the grinders, are too old (and too important) to risk moving off their foundations at all. Still others, like the massive core drill used to hollow-out incoming barstock, are both. For now, at least, these “monuments” must remain in place.

However, a lean-minded organization doesn’t have to let inherent limitations make a monument of outmoded thinking. Screws may still move relatively long distances at Wear Technology, and even partial cells may be impossible in some cases, but there’s a method to the seeming madness, a system that helps keep everything on track and on time and generally flowing as efficiently as possible. Two employees, freed from other tasks by department-focused process improvements, now dedicate most of their time to transporting work from one station to the next according to accompanying job travelers.

Known as “water striders,” these wanderers enable other employees to stay at their workstations. This has meant no more delaying production to load pairs of screws onto carts (assuming one was available) and wheel them through narrow, crowded aisles to the next station, possibly stopping to chat along the way. Rather, the water striders handle these tasks for everyone in the shop, keeping carts and hoists organized and meticulously checking jobs in and out as they go. Based on the WSU students’ data, implementing water striders has saved 5-8 total hours of productive time per day. Aisles are clearer, and the flow of personnel, parts and information is less chaotic, the students say.

Flexible Mindset, Flexible Tools

The sequence of steps facilitating the relocation of the pre-inspection department may seem relatively straightforward. However, determining the most efficient equipment groupings can be difficult in a complex HMLV operation, at least without the right tools. One example is the Production Flow Analysis and Simplification Toolkit (PFAST), a software suite co-developed by Dr. Irani and Dr. Smart Khaewsukkho when both were at the Ohio State University. In short, this software segments a facility’s entire product mix based on part quantity and revenue, then compares routing sequences to further subdivide those segments into part families that can be produced by co-locating machines in close proximity. These co-located machines form hybrid cells with multiple entry and exit points for parts with similar, but not identical, processing sequences (for example, milling to turning rather than vice versa). Machines can be employed in different combinations, in isolation or even in combination with machines in other “cells” if need be.

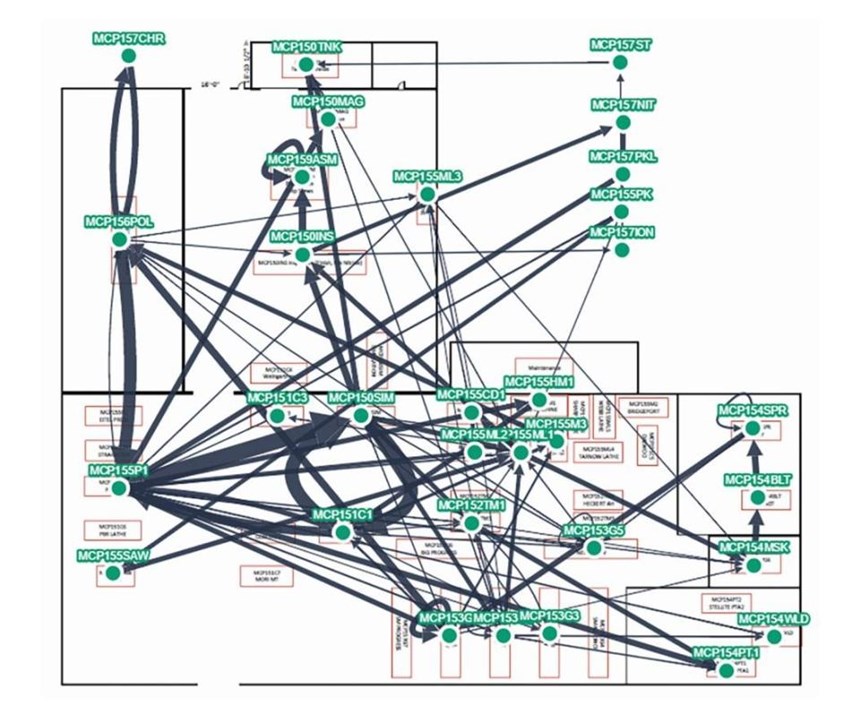

Dr. Irani also had access to another, complementary tool, one designed specifically for on-the-fly, virtual layout reconfiguration with instant feedback on the results of individual equipment moves. Aptly named Sgetti and developed by Dr. Khaewsukkho, this software program uses PFAST output or raw data to generate a spaghetti diagram of product routings. Unlike the output of manual value stream mapping exercises, this map can be generated in seconds, and it’s more than just a static snapshot of a single product routing. It displays any combination of product routings chosen by the user. Individual workstations are represented by bubbles that can be clicked and dragged to new locations at will. Changing any routing automatically updates the entire map, and the software immediately outputs the resulting reduction (or increase) in total material handling distance as a percentage.

Traditional lean tools also have a place in Wear Technology’s transformation. As Dr. Irani puts it, in a cell or something close to it, lean and job shop lean become one. Standardized work instructions, 5S, employee-led kaizens—all are critical at Wear Technology, but employed selectively to meet strategic, often department-specific goals. For example, the polishing area features a kanban system for replacing handheld tools as well as more ergonomic equipment to improve throughput specifically in that area. Complemented by specific training from Mr. Lonneman on tools and strategies like gemba walks and quick-response quality control, such targeted improvements help focus staffers’ attention on only value-added activities. Freeing up existing employees to become water striders is just one example.

Human Flow Facilitators

Water striders are the most literal example of people driving lean manufacturing at Wear Technology, but they certainly aren’t the only ones. Masses of data had to be collected to justify every move, lest the crew risk wasting time or sabotaging one reform with another. In fact, lack of data prevented Dr. Irani from fully leveraging PFAST, a highly complex, proprietary tool that’s packaged as part of his consulting services. At the time, the shop had outlined only generalized part routings that didn’t account for all the potential nuances in a pair of screws’ progression through the shop. As a result, PFAST output was of limited use for experimenting with different layout options in Sgetti, a system that’s commercially available from Dr. Khaewsukkho. Supplementing the PFAST output and making the most of Sgetti required developing a series of if/then flow charts covering virtually all possibilities.

This responsibility fell mostly to the students, and it certainly hasn’t been the only task keeping these three full-time lean champions busy. Armed with stopwatches and notepads, they quickly became a common sight on the shop floor, visiting virtually every station to, among other activities, measure processing times; verify time spent setting up machines, retrieving tools and other activities; standardize procedures and work instructions; and oversee various, specifically targeted improvement initiatives. Combining senior consulting expertise with this full-time support wasn’t free, but the investment has already paid off, at least as far as Mr. Keating is concerned. “We certainly wouldn’t have gotten to where we are today,” he says.

The students, in turn, emphasize that they haven’t been the only “boots on the ground” driving lean change at Wear Technology. Standing with a stopwatch during lengthy processes like polishing, which can take anywhere from eight to more than 40 hours per screw, can be impractical. Even barring lengthy cycles, each station presents a lot of data to track. For instance, accurately and comprehensively separating non-value-added time from value-added time might require determining, say, how long screws wait at a station before processing, or the amount of time spent processing individual zones of a screw. The operators themselves are often responsible for tracking this kind of information as they go about their work.

More importantly, their engagement goes beyond complying with management’s request to track data (or to perform any other activity). The students say they can’t express enough gratitude to the shopfloor staff, who have been happy to explain the intricacies of their work, help determine what data to track, and even suggest process improvements.

As an example, Mr. Varkey cites the re-location of pre-inspection resources away from the main factory and into the warehouse. The move looked great on paper. Dedicated pre-inspection employees would continue to perform initial cleaning and hand tool measurements on used screws as they always have, but conducting these activities in the warehouse instead would eliminate the interference that comes with bringing incoming work into the main factory. Screws would move there only for simulation, straightening and inspection on a Magnaflux magnetic particle inspection machine, which uses magnetized oil and ultraviolet light to check for cracks and imperfections. Afterwards, they’d return to the warehouse for storage while customers decide whether to proceed with the job.

However, employees balked at the idea of repeatedly moving screws to the main factory—often in cold, harsh weather—for the latter three steps, only to bring them back to the warehouse again afterwards. Management listened, and the process is more efficient as a result. No longer do production employees in the main facility handle simulation, straightening and the Magnaflux inspection, tasks that they often couldn’t get to anyway before completing other work. Rather, investing in an older Magnaflux unit for the pre-inspection department’s exclusive use in the warehouse provided employees with everything they need to complete most pre-inspections without leaving their stations. The viability of this strategy emerged largely through talking things out with the people doing the work, who revealed (surprisingly) that most incoming screws do not actually require straightening operations. Installing a device on the Magnaflux to verify straightness has enabled them to stay at their stations without the time and expense of installing a new press.

Buy-in from people can sometimes be difficult to link directly to quantifiable improvements, whether the 100-miles-per-year reduction in overall material handling distance, the average five-day-plus leadtime reduction in pre-inspection, the roughly 50 percent polishing throughput improvement, or any of the other gains described above. However, Wear Technology’s experience demonstrates that numbers don’t always tell the full story of lean transformation. Moving forward, Mr. Varkey says he has no doubt that the continued enthusiasm and engagement of the shopfloor staff will be among the most reliable indicators of how sustainable change will really be. So far, fostering that engagement has been largely about communication. “People understand that a lot of this is really about making their jobs easier—that getting such and such data is how we’re going to justify getting them a new crane, or whatever the issue may be,” he says.

Related Content

Finding Skilled Labor Through Partnerships and Benefits

To combat the skilled labor shortage, this Top Shops honoree turned to partnerships and unique benefits to attract talented workers.

Read MoreSolve Worker Shortages With ACE Workforce Development

The America’s Cutting Edge (ACE) program is addressing the current shortage in trained and available workers by offering no-cost online and in-person training opportunities in CNC machining and metrology.

Read MoreIn Moldmaking, Mantle Process Addresses Lead Time and Talent Pool

A new process delivered through what looks like a standard machining center promises to streamline machining of injection mold cores and cavities and even answer the declining availability of toolmakers.

Read MoreIMTS Takeaways From the Modern Machine Shop Editorial Team

The first in-person IMTS in four years left the MMS editorial staff with a lot to digest. Here are a few of our takeaways from the show floor.

Read MoreRead Next

The Future of High Feed Milling in Modern Manufacturing

Achieve higher metal removal rates and enhanced predictability with ISCAR’s advanced high-feed milling tools — optimized for today’s competitive global market.

Read MoreInside Machineosaurus: Unique Job Shop with Dinosaur-Named CNC Machines, Four-Day Workweek & High-Precision Machining

Take a tour of Machineosaurus, a Massachusetts machine shop where every CNC machine is named after a dinosaur!

Read MoreIMTS 2024: Trends & Takeaways From the Modern Machine Shop Editorial Team

The Modern Machine Shop editorial team highlights their takeaways from IMTS 2024 in a video recap.

Read More

.jpg;maxWidth=300;quality=90)