Shrinking Costs: The Tool Life and Cycle Time Advantages of Shrink-Fit Tooling

A Tier-One automotive supplier measures the value of a toolholder change.

Share

How can a production facility increase productivity and reduce consumable tooling costs without changing anything about the cutting tool itself? Wescast Industries Inc., the world’s largest manufacturer of cast manifolds and housings for passenger cars and light trucks, discovered a way to do this and has documented the extent of its success.

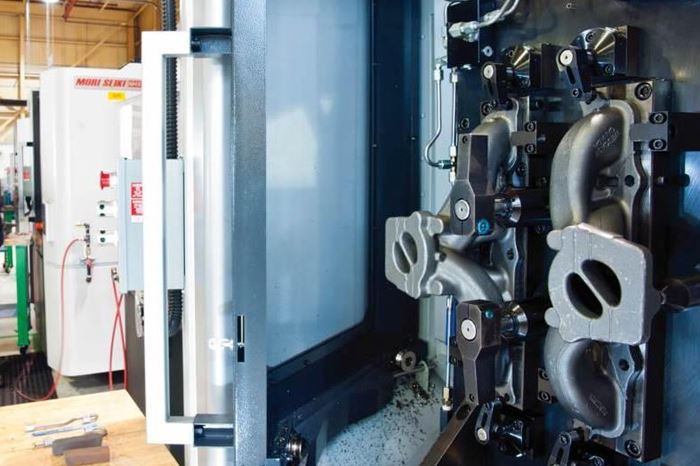

As a Tier-One supplier to the automotive market, Wescast specializes in the casting of complex high-temperature components. Considered a leader in metallurgical development, Wescast says it employs its team members’ knowledge and experience in this area to tailor solutions to customers. The company designs and manufactures components including exhaust manifolds, turbocharger housings, integrated turbo manifolds and other powertrain parts. A commitment to employee engagement in continuous improvement is part of the culture, and that improvement recently turned to tooling.

When the question of evaluating a toolholding upgrade came to Bob Phillips, manufacturing technician at Wescast’s Macomb Township, Michigan, location, he was happy to investigate a possible alternative. “I was looking for a way to get our machines running truer,” he says. He then implemented a comprehensive testing platform for evaluating a proposed toolholder change.

The change involved a shift from collet-chuck holders to shrink-fit holders. According to Mike Martin, Haimer USA regional manager, the improved holding and runout of the shrink-fit tools could reduce cycle time by 5 percent for all round tools held with these holders while tool life increased 25 percent.

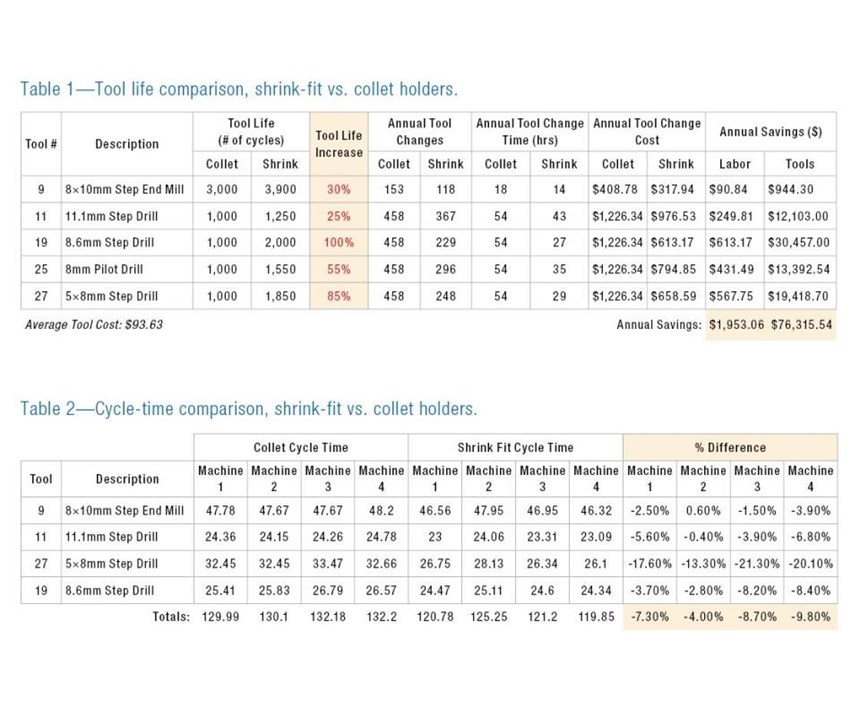

To test the assertions, Mr. Phillips isolated one machining cell of eight machines and used five cutting tools in this cell to conduct a study. The parts machined were cast iron exhaust manifolds. In four machines, the existing collet-chuck holders were left to run as usual, without changing cutting parameters. In the other four machines, Haimer shrink-fit chucks replaced the existing collet chucks and adjustments were made to feeds and speeds, generating the 5 percent improvement for each tool. Over three months, data were gathered across three shifts, six to seven days per week. These data included cycle times, tool life and tool-change times. The charts above summarize the experiment’s findings.

As Table 1 shows, improvements in tool life for the five tools ranged from 25 to 100 percent, and Mr. Phillips even notes that the shop continues to see tool life increase beyond the results recorded in the study. The annual cost savings from this additional tool life on Wescast’s 16-machine line, factoring direct and indirect labor costs as well as tool-change savings, adds up to more than $78,000.

Significantly, this application was not high-speed machining and did not involve advanced materials. A common misperception views these as the appropriate applications for shrink-fit holders. All but one of the tools in this case were step drills, running at speeds slower than 8,000 rpm in cast iron.

The increase in tool life in these applications is (we at Haimer believe) a result of a combination of the shrink-fit toolholding systems’ runout accuracy, balance integrity, taper accuracy and inherent ability to maintain these properties from one tool change to the next.

Meanwhile, as Table 2 shows, the average cycle-time savings for the machines and tools using shrink-fit holders was 7.5 percent after further refinements in the cutting parameters. Assuming a 40-hour workweek and three shifts, this time savings translates to one week of saved machining time per year.

In addition to the productivity gains, Mr. Phillips says Wescast also “saw indirect benefits via the simplification of the tool-change process and through the elimination of cleaning processes associated with collets.” Timely collet cleaning processes and collet replacement schedules to help stabilize runout accuracy could be eliminated with the toolholder switch, and possible variations between team members in collet tightening during tool replacement become non-factors with shrink fit, he says.

In total, when also factoring in the value of the productivity, switching from mechanical collet chucks to shrink-fit chucks produced process improvements saving more than $95,000 in total annually for the 16 CNC machines. The investment to tool up all 16 machines, by comparison, was $56,064. Much of that expense went to the shrink machine. The average cost of a shrink-fit chuck was $262, versus the average price of $204 the shop had paid for collet chucks. Additionally, the elimination of wearable mechanical components such as collets, nuts, rings and bladders reduces the need for maintenance or replacement, further saving time and money.

Mr. Phillips notes there was skepticism in his shop at first. “At a glimpse, the shrink-fit holders were not as bulky as our collet chucks, and the perception was that they would not be as rigid or secure as a result,” he says. In addition, he says a toolholder system tested in the past had been a disappointment. But the well-documented test described here produced results that answered the objections or apprehension. The shrink-fit system was adopted, and the goal of reducing costs via toolholding was achieved, in a success that might well be applied to other Wescast production facilities in the future.

About the author: Drew Strauchen is vice president of business development for Haimer USA.

Related Content

How to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

Read MorePowRgrip Responds to Three Tooling Trends

Rego-Fix’s PowRgrip tooling system has expanded over the past 20 years to incorporate a wider range of tool sizes, as well as automation.

Read MoreJergens Pull Studs Enable Quick Changeovers

SP140 and K02 pull studs offer quick-change solutions for vise or gripper jaws, electronic component manufacturing, packaging machines, medical technology and automation.

Read MoreLyndex-Nikken Toolholders Offer Stable, Versatile Machining

Polygonal shank toolholders provide a rigid connection between the tool and machine — ideal for all processes both in turning and milling.

Read MoreRead Next

All-Directional Turning Cuts Cycle Times 50%

Sandvik Coromant’s PrimeTurning process allows turning and facing in all directions, delivering dramatic increases in high volume production. Cycle time reductions of 50% or more can be achieved.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More

.png;maxWidth=300;quality=90)