Articles

Online Marketplace Helps Shops Stay at Maximum Capacity

Orderfox.com provides a global database connecting buyers and sellers of CNC machining services.

Read MoreAluminum Material Removal Rate New World Record?

Sweden’s Modig Machine Tool says it has achieved the world’s highest material removal rate in aerospace-grade aluminum at 1,001 cubic inches per minute.

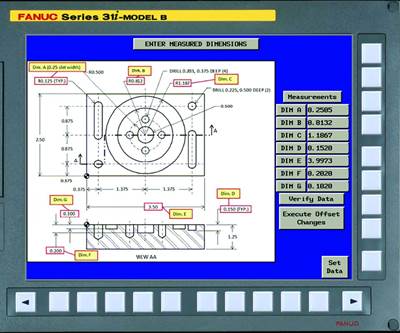

Read MoreControlling Your CNC Display Screens

CNC manufacturers have begun offering programs that allow end users to customize how display screen pages look and work.

Read MoreIMTS 2018: Identify the Need for New

New technology enables shops to make smarter decisions, leading to boosts in productivity, product quality and profitability. Find it all at the International Manufacturing Technology Show (IMTS).

Read MoreManufacturing News of Note: November 2017

Acquiring a cutting tool manufacturer, growing apprenticeships in the United States and other industry news.

Read MoreTooling up for Deep-Hole Machining

Imparting complex geometry on the inside (and the outside) of workpieces requires the right equipment, the right cutting tools and the expertise to make the most of both.

Read MorePainting with Tool Paths

Recent MMS stories and archived content alike demonstrate that there’s plenty of room for art and craft in metalcutting applications.

Read MoreAdditive Manufacturing Magazine Expanding in 2018

New writing staff and expanded industry events anticipate a transition from four print issues per year to six, starting in 2018.

Read MoreUnited Grinding Unveils New Ohio Facility

The new facility will consolidate the company’s offerings in a single location in Miamisburg, Ohio.

Read MoreThe Link Between Gaging and Tool Cost Savings

New software delivers the next step for Renishaw’s programmable gaging system: a mechanism for changing cutting tools when they are truly at the end of their life, not after an arbitrary number of pieces have been run.

Read MoreSand 3D Printing Expands Options for Metal Casting

A foundry featured in Additive Manufacturing’s November issue uses sand 3D printing to create cores and molds for casting, no patterns necessary.

Read MoreKeep up with Machine Shop Digitalization

Sandvik Coromant’s recent roundtable discussion of machine shop digitalization focused on three key ideas: Digitalization is a competitive advantage. The investment is reasonable and has a quick payback. Shops must start the journey now or get left behind.

Watch