How Champions Can Develop a Thriving Workforce

Having a workforce development champion in your shop is more critical now than ever before. Here are five techniques your champion can apply to attract and retain new talent.

Share

The manufacturing skills gap remains wide. According to the 2018 Deloitte and The Manufacturing Institute skills gap and future of work study, 51% of executives cited “maintaining or increasing production levels to satisfy growing customer demand” as the biggest challenge resulting from the inability to fill open jobs. The study also predicted an increase in total unfilled jobs between 2018 and 2028 from 2 to 2.4 million, meaning expectations point to the situation getting worse before it gets better.

A shifting skill set toward more advanced technology and automation is one cause manufacturers are blaming on the lack of talent within the industry. This is followed by a negative perception of students and their parents toward manufacturing and baby boomer retirements.

So, precision machine shops have two basic options: Do nothing and hope the problem will solve itself or be proactive and dedicate time to solving the problem themselves. Successful shops choose the latter and, typically, have one person championing the workforce development initiatives.

That “champion” devotes his or her time to creatively execute ways to attract the young generation to a career in manufacturing. The champion also works to develop relationships within the community to spur interaction with young people as well as their parents.

When champions diligently work together on ways to increase young people’s interest in the trade, it’s possible to turn these numbers around and prove these negative predictions wrong. But to make a positive change will take commitment from every shop across the country to invest its time and energy in workforce development, and that starts by identifying those champions.

Here are five initiatives your shop’s champion can take to attract and keep talented young prospects.

1. Work Directly with Local High Schools

Champions are needed in their communities — and, in particular, high school machining programs — to change misconceptions about manufacturing careers, and to educate students and their parents about the opportunities available to them in this industry.

Robin Rutschilling at Clippard Instrument Laboratory believes it’s important to take his interns on field trips, such as to the Toyata plant in Georgetown, Kentucky. “It’s free and you can set it up online. We usually get there at 9 and then we are back at work by 1 p.m. or so,” Mr. Rustchilling says. (Photo courtesy of Clippard Instrument Laboratory Inc.)

Clippard Instrument Laboratory Inc. (Cincinnati, Ohio) has been working with one local high school’s machining program for about 45 years, and usually hires one or two students per year from that school. Students who are that young start with the company’s summer internship program. Then, if they show promise, they are offered a position upon graduation.

“They are expected to continue their education once hired by us, and we pay for everything outright,” says Robin Rutschilling, Clippard’s director of operations (and workforce development champion). “And that could be anything, not just college. We send them to technical training for maybe CNC or robot programming. We’ll send them to Boston, California or wherever the training may be.” Currently, Clippard has a half dozen employees taking college courses to further their machining education.

Working with high schools not only means offering internships for the students but also supporting the machining instructors. “Teachers are understaffed and under budget. They are just trying to get through the day,” Mr. Rutschilling says. “When machine tools are broken, we’ll send two maintenance experts there and fix them on our dime. We will pay for the parts, put the machine back together and fix it.”

He says whatever resources a company has, even if it is a two- to three-person job shop, it’s possible to get involved in such a school program. He suggests it could be as simple as donating cutting tools or old inserts.

Supporting robotics teams is another way to show support at a high school level. Mr. Rutschilling says he takes 20 to 25 Clippard employees every year to its local high school Skills USA competition. “Then, the instructors know how committed we are to the teacher, the students and the program,” he says. “They remember these gestures.”

Several years ago, Smith and Richardson Inc. (Geneva, Illinois) decided to hire a retiring vocational education teacher, Ron Brown, to promote manufacturing careers, provide outreach to the high schools and middle schools, offer an onboarding experience, develop training programs and facilitate a positive learning culture. Rich Hoster, company president, says, “Ron’s relationship with the schools has allowed us access to talented students who are graduating from high schools and are not going on to four-year colleges.”

2019 summer interns and quality inspectors pose outside the main entrance of Smith and Richardson in Geneva, Illinois. Left to right: Joe Farrel, quality inspector, Purdue University; Brad Bode, quality inspector, Purdue University; Zac Kovach, intern, Iowa State University; Jameson Red, intern, Geneva High School; Nathan Cizek, intern, Bradley University; and Ryan Leo, intern, Bartlett High School. (Photo courtesy of Smith and Richardson Inc.)

Mr. Brown, director of education and training at Smith and Richardson, has created internships, both summer and year-round, as well as job shadow and work study programs for both high school and college students. By creating these programs in-house, the company has hired much of their new talent from this pool of potential candidates.

Joe Farrell, freshmen mechanical engineering student at Purdue University, inspects job parts at the Mazak station as part of his responsibilities at Smith and Richardson. Joe says although he had design process experience in high school, the internship allowed him to gain valuable experience in production manufacturing and the role of quality control. (Photo courtesy of Smith and Richardson Inc.)

Once hired, these new employees start in an apprenticeship program that combines internal and external training resources. “The external training is done through partnerships with the Technology and Manufacturing Association (TMA) in Schaumburg, Illinois, as it offers both hands-on and classroom training as well as apprentice training,” Mr. Hoster says.

Parrish Castor, director of quality and technology, DaCruz Manufacturing (Bristol, Connecticut), says DaCruz’s primary candidate pool has come through the local high schools. “We have a presence within our town and technical high schools in our area that tend to provide opportunities for us,” says the Production Machining 2018 Emerging Leader. “Plus, there are committees that work on providing technical schools and employers with resources to provide adequate training for the next generation of manufacturers to be successful.”

These connections have led the company to promising candidates who are able and willing to enter the manufacturing workforce. “We have hired people from programs such as Women in Manufacturing and Connecticut Center for Advanced Technology,” Mr. Castor says. He adds that DaCruz has had successful hires through temporary staffing firms and internet advertisements, although, historically, these sources have been hit or miss.

2. Host Open Houses

Workforce development champions find ways to welcome the community into their facilities. Doing so offers the chance for shops to prove to the next generation that their work environments are not dark and dirty places, and that, in fact, they use the latest technology in a clean workspace with plenty of room for career growth.

“Many high school candidates have come through our shop during the annual Manufacturing Day that we host at our facility,” Mr. Castor says. “When the kids see the shop and realize that the stigma of manufacturing has changed greatly, they open their eyes to the possibility of a future in manufacturing.”

He says Manufacturing Day also gives him the opportunity to connect with the students’ parents and caregivers so they, too, realize the opportunities within the industry and can support or persuade their children to consider manufacturing as a career choice.

Although Manufacturing Day is an optimal opportunity to welcome the community to a shop for a day, open houses don’t need to be an all-day event. Mr. Rutschilling says he invites groups of only six or seven students from machining programs at local high schools that will stop in for a three- to four-hour tour. “I might be a part of organizing the visit, but I usually have the staff that graduated from that particular program lead the tour,” he explains.

Sponsoring open houses is important, but so is attending trade school open houses, according to Mr. Rutschilling. For him, it’s an opportunity to recruit new talent for Clippard and support the school’s machining program at the same time.

He says Whitewater Career Center (Connersville, Indiana) has an excellent program and many of his top employees graduated from there. As a member of its board of advisors, Mr. Rutschilling understands that it’s his duty to attend the school’s open houses to foster the relationship he has with the school because they help each other.

“There will be eighth, ninth and tenth graders there with their parents to see what the manufacturing trades are all about,” he says. “I take the graduates from their program who

Attending trade school open houses is an opportunity to recruit new talent for Clippard Instrument Laboratory and support the school’s machining program at the same time. Graduates from the program and current Clippard employees meet the interested students and tell them about how much they enjoy their jobs. (Photo courtesy of Clippard Instrument Laboratory Inc.)

currently work for Clippard with me. They want to go back there and see their teachers again, so it’s kind of a reunion for them. We meet the interested students. The young people I bring talk to them about how cool their careers are, and then I’ll stand back and talk to the parents.”

Mr. Rutschilling says Clippard ends up hiring one person he meets at the annual open house each year.

3. Create an Apprenticeship Program

Offering an apprenticeship program is another opportunity for champions to grow next-generation talent within the industry at their own facilities. These programs guarantee jobs for the students who enter them, as long as they display a positive attitude and a solid work ethic with a desire to learn about the latest machine tool technology. It’s a win/win for both parties involved — a shop has talent graduating from the program annually and the students have a good job with a promising career path waiting for them.

“Our state government has reinvigorated the effort to steer people into apprenticeship programs,” Mr. Castor says. “They have worked with DaCruz Manufacturing to develop a program that is tailored to our operation, while providing a valuable skill to the participant. Whether or not they stay with our organization for the span of their career or take their skills elsewhere, they will be benefiting our industry.”

“These programs offer some type of salary match for a certain number of weeks.”

Apprenticeship programs don’t have to be internal in order to support them, however. There may be local apprenticeship opportunities that don’t require a shop to begin its own program. For instance, Component Bar Products (O’Fallon, Missouri) works closely with its county’s workforce development program. “We have graduated two employees from their apprenticeship program,” says Darrel Keesling, company president. “These programs offer some type of salary match for a certain number of weeks.”

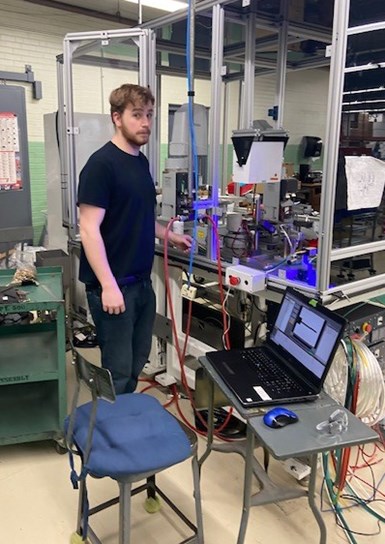

4. Provide In-House Training

Deciding who to hire is sometimes tricky: does a shop hire a person because it likes his or her personality, or does it continue to search for the perfect machinist/operator with the right skill set? Several workforce development champions state that it’s most advantageous to commit to training good people who are willing to learn.

“Hiring the person instead of the skill is a successful way to approach hiring,” Mr. Castor explains. “You have to commit to the work required to further your employees’ skills and careers, and they can then further the life of your business.” He says, for his company, it comes down to finding capable individuals who show the aptitude to become talented and productive contributors.

Mr. Rutschilling agrees that it’s critical to give youth in machining programs a chance to prove themselves and not expect them to be knowledgeable in the beginning. When he hires high school students for his program, he talks to them first about what is expected of them.

“I’ll sit down with them and tell them that they need to come to work every day and have a good attitude, and be able to accept constructive criticism,” he explains. “They also have to be able to learn while they are here. I know they don’t have a lot of experience, so I always tell them this will be the longest interview they’ll ever get.”

From that initial interview, Mr. Rutschilling strives to give students a lot of different opportunities during their time at Clippard.

Clippard strives to give its student workers many opportunities during their time at the company, from operating a CNC or manual machine to working in the stockroom. (Photo courtesy of Clippard Instrument Laboratory Inc.)

Projects vary from operating a CNC machine to running a manual machine to working in the stockroom.

He realizes students don’t know what they want to do or what they are good at until they experience it for themselves, and even then it might take some persuading to have them understand what they are passionate about. “If we can align their passion with a job in our company, I’m going to have a happy and loyal employee,” he says. “So, if we stay in touch with them during their time here, we may learn what their passions are before they do.”

Because trade schools, no matter the kind, don’t have the capacity to train each student to their full potential, Mr. Rutschilling believes that it’s Clippard’s duty to train — and continually train — so employees can grow their skills. He says most employees like to be challenged, so he keeps that in mind as he assigns work to individuals.

“Some people might ask ‘what happens if you train and you pay for all their schooling and then they leave to go to another company?’ he says. “My thought is, what happens if you don’t train them and they stay? Their skills don’t get better.”

5. Implement Programs to Retain New Hires

Once good employees are found, shops must find ways to retain them. According to Smith and Richardson’s Mr. Hoster, keeping the work environment fun and offering benefits that young people appreciate is crucial. Here are a few initiatives that have been successful at his company:

- Set up monthly team building events in which the company cooks or caters lunch, and employees complete a team building exercise

- For Manufacturing Day events, hold a t-shirt design contest whereby the winner receives recognition and a gift

- Offer flexible hours as needed

- Provide a front-loaded, paid time-off policy and paid sick days

- Pay 90% of employee benefit costs and 100% of short- and long-term disability

- Create annual performance discussions and allow employees to set their own goals and training needs each year

- Find ways to celebrate successes

- Have an open-door policy

Zac Kovach, freshmen mechanical engineering student at Iowa State University, performs inspection sheet tolerance checks on the comparator. Zac says he enjoyed experiencing all phases of precision machining at Smith and Richardson. (Photo courtesy of Clippard Instrument Laboratory Inc.)

Component Bar Products’ Mr. Keesling also believes good benefits are indeed an important offering for most new hires, and a great way to retain the best talent. He says his company offers a 401k plan and above-average health benefits. He describes its work environment as casual, offering time off without pay and overtime, in some cases. The company has also raised its starting wages to attract new hires.

Mr. Keesling also says the shop hired someone who is responsible for most of the company’s hourly employees, noting that “He has brought a significant amount of professionalism to lead-man development/engagement and overall employee performance reviews.”

Commitment Equals Success

Manufacturing’s employment statistics support the fact that champions of workforce development are in critical demand in order to narrow down the skills gap.

These champions must be committed to attracting future talent to their organizations. They need to realize the importance of building relationships with students as well as with machining programs and other science, technology, engineering and mathematics (STEM) initiatives within communities. They must have a strong desire for their shops and the manufacturing industry as a whole to thrive, putting their hearts into finding productive contributors and creating a steady educational path for them within their organizations.

Does your shop have a champion? If the answer is “no,” why not?

Clippard Instrument Laboritory Inc. | 513-521-4261 | clippard.com

Component Bar Products Inc. | 636-939-5956 | compbar.com

DaCruz Manufacturing | 860-584-5315 | dacruzmfg.com

Smith and Richardson Inc. | 630-232-2581 | smithandrichardson.com

Related Content

Same Headcount, Double the Sales: Successful Job Shop Automation

Doubling sales requires more than just robots. Pro Products’ staff works in tandem with robots, performing inspection and other value-added activities.

Read MoreBuilding Machines and Apprenticeships In-House: 5-Axis Live

Universal machines were the main draw of Grob’s 5-Axis Live — though the company’s apprenticeship and support proved equally impressive.

Read MoreFinding Skilled Labor Through Partnerships and Benefits

To combat the skilled labor shortage, this Top Shops honoree turned to partnerships and unique benefits to attract talented workers.

Read MoreSolve Worker Shortages With ACE Workforce Development

The America’s Cutting Edge (ACE) program is addressing the current shortage in trained and available workers by offering no-cost online and in-person training opportunities in CNC machining and metrology.

Read MoreRead Next

Developing STEM's Future Workforce

To keep our competitive edge in the world market, K-12 education must continue to improve in every state. These programs are helping to build a foundation, but we need more to support the growth of our workforce.

Read MoreWorkforce Development: What We Can Do Better

The causes of our workforce issues may be out of our hands, but there are definitely steps we can take to improve our shop’s response to the issue.

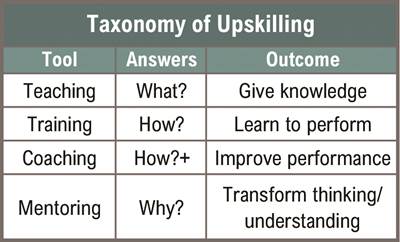

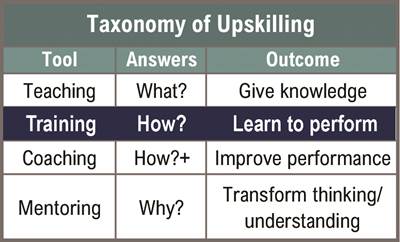

Read MoreWorkforce Development—Training Shows How

To expand on his “Workforce Development—What We Can Do Better” article, Miles Free explains the Who, What, Where, When, Why, How and How Many of one of the four upskilling tools—training.

Read More

.jpg;maxWidth=300;quality=90)