Five Reminders For Machining Graphite

Graphite machining can be a tricky business, so keeping certain issues top of mind is vital to productivity and profitability.

Share

.png;maxWidth=45)

DMG MORI - Cincinnati

Featured Content

View More

Takumi USA

Featured Content

View More

Graphite can prove tricky to machine, particularly for EDM electrodes that require outstanding accuracy and structural consistency. Here are five key points to keep in mind when working with graphite:

1. Mind Your Grade

Graphite grades are visually difficult to distinguish, but each features unique physical characteristics and properties. Grades of graphite are grouped into six classifications by average particle size, but only the smaller three (with particles measuring 10 microns or smaller) see regular use in modern EDM. How grades rank within classifications is an indicator of potential applications and performance.

According to an article by Doug Garda (of Toyo Tanso when he contributed to our sister publication, MoldMaking Technology, but now of SGL Carbon), roughing uses grades with particle sizes ranging from 8 to 10 microns. Less-precise finishing and detailing applications employ grades with 5- to 8-micron particle sizes. Electrodes made from these grades are often used to create forging dies and die-cast molding dies, or used in less-complex powdered and sintered metal applications.

Fine detailing work and smaller, more intricate features are better suited for grades with 3- to 5-micron particle sizes. Applications for electrodes in this range include wire cutting and aerospace.

Ultra-fine, precision electrodes, which employ graphite grades with particle sizes of 1 to 3 microns, are often required for exotic aerospace metal and carbide applications.

2. Ensure Ideal Properties

Writing for MMT, Jerry Mercer of Poco Materials identifies particle size, flexural strength and Shore hardness as three key determinants of performance during electrode machining. However, the graphite’s microstructure is often the limiting factor in how the electrode performs during final EDM operations.

In a different article for MMT, Mercer says flexural strength should be above 13,000 psi to ensure graphite machinability into deep, thin ribs without breakage. The graphite electrode manufacturing process is lengthy and can require detailed, difficult-to-machine features, so ensuring durability like this helps to keep costs low.

Shore hardness measures the machinability of graphite grades. Mercer warns that graphite grades which are too soft can clog cutter flutes, slowing down the machining process or packing the hole with dust that can stress the hole walls. Reducing feeds and speeds in these situations can prevent errors, but this will increase machining time. Hard, small-grain graphites can also cause material at the rim of the hole to chip during machining. These materials can also be very abrasive to cutters, causing wear that impacts the integrity of the hole diameter and increases the cost of the job. Generally, avoiding deflection at high hardness values requires reducing machining feeds and speeds by 1% for each point of Shore hardness higher than 80.

Due to the way EDM produces a mirror image of the electrode in the part being machined, Mercer also says a tightly packed, uniform microstructure is vital for graphite electrodes. Uneven particle boundaries increase porosity, thus increasing the erosion of particles and hastening the failure of the electrode. Non-uniform microstructures also result in uneven surface finishes during initial electrode machining — a problem exacerbated on high-speed machining centers. Hard spots in graphite can also cause tool deflection, throwing the final electrode out-of-spec. This deflection can be slight enough that angled holes appear deceptively straight at the point of entry.

3. Use the Right Technology

There are dedicated machines for graphite machining, but while these will greatly speed along production, they are not the only machines manufacturers can use. Aside from dust control (covered later in the article), past MMS articles have reported on the benefits of a machine with a fast spindle and a control with a high processing speed for graphite manufacturing. Ideally, the fast control should also have look-ahead functionality, and the user should utilize toolpath optimization software.

4. Consider Impregnation for Superior Stability

When impregnating graphite electrodes — that is, filling the holes of the graphite microstructure with micron-sized particles — Garda recommends using copper as it can stabilize machining of exotic, copper and nickel alloys, such as those used in aerospace applications. Copper-impregnated graphite grades create finer finishes than non-impregnated grades of the same classification. They also enable stable machining when working with unfavorable conditions such as poor flushing or inexperienced operators.

5. Invest in Dust Ventilation

Although synthetic graphite — the kind used to fabricate EDM electrodes — is biologically inert and thus not as initially hazardous to humans as some other materials, improper ventilation can still cause problems, according to a third article from Mercer. Synthetic graphite is electrically conductive, posing issues around equipment that can short out upon contact with foreign conductive materials. Also, graphite impregnated with materials like copper and tungsten requires additional care.

Graphite dust is invisible to the human eye in small concentrations, Mercer explains, but it can still cause stinging, watering and redness. Contact with the dust may be abrasive and mildly annoying, but absorption is unlikely. The exposure guideline for time-weighted average (TWA) for graphite dust over an 8-hour period is 10 mg/m3, which is a visible concentration that should never occur with a dust collection system in use.

Excessive exposure to graphite dust over extended periods of time can lead to inhaled particles of graphite being retained in the lungs and bronchi. This causes a serious, chronic form of pneumoconiosis called graphitosis. Graphitosis is typically associated with natural graphite, but has happened in rare circumstances with synthetic graphite.

Accumulated dust in the workplace is highly flammable, and (in a fourth article) Mercer says it can explode under certain circumstances. Dust fires and deflagration occur when ignition meets a sufficient concentration of fine particulates suspended in air, with explosions more likely to occur if the dust is dispersed in significant volume or is in a contained area. Controlling any one hazardous element (fuel, oxygen, ignition, dispersion or confinement) drastically lowers the possibility of a dust explosion. Most times, the industry focuses on fuel by removing dust at the source through ventilation, but shops should consider all factors for maximum safety. Dust control equipment should also have explosion relief vents or an explosion suppression system, or be installed in an oxygen-deficient environment.

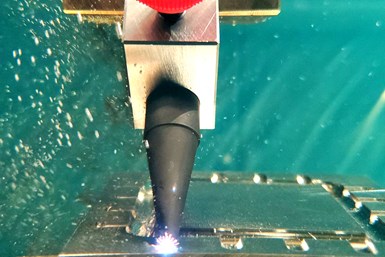

Mercer identifies two primary methods for controlling graphite dust: high-velocity air systems with dust collectors — which can be fixed or portable, depending on the application — and wet systems that saturate the area around the cutter with fluid.

Shops doing a limited amount of graphite machining can use a portable unit with a high-efficiency particulate air (HEPA) filter that can be moved from machine to machine. However, shops that machine significant amounts of graphite should generally use a fiixed system. The minimum air speed for capturing dust is 500 feet per minute, with speed increasing inside the duct to a minimum of 2000 feet per second.

Wet systems flush away dust at the risk of the fluid “wicking” (being absorbed) into the electrode material. Not removing the fluid prior to placing the electrode in the EDM can result in contamination of the dielectric oil. Operators should use water-based solutions, as these wick less easily than oil-based solutions. Drying the electrode before EDM use typically involves placing the material in a convection oven for about one hour at a temperature slightly exceeding the vaporization point of the solution. The temperature should never exceed 400 degrees, as this makes material oxidize and erode. Operators should also never use compressed air to dry the electrode, as the air pressure merely forces the fluid deeper into the electrode structure.

Related Content

How to Successfully Adopt Five-Axis Machining

While there are many changes to adopt when moving to five-axis, they all compliment the overall goal of better parts through less operations.

Read MoreVolumetric Accuracy Is Key to Machining James Webb Telescope

To meet the extreme tolerance of the telescope’s beryllium mirrors, the manufacturer had to rely on stable horizontal machining centers with a high degree of consistency volumetric accuracy.

Read More5 Tips for Running a Profitable Aerospace Shop

Aerospace machining is a demanding and competitive sector of manufacturing, but this shop demonstrates five ways to find aerospace success.

Read More6 Machine Shop Essentials to Stay Competitive

If you want to streamline production and be competitive in the industry, you will need far more than a standard three-axis CNC mill or two-axis CNC lathe and a few measuring tools.

Read MoreRead Next

5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More

.jpg;maxWidth=300;quality=90)