DNC: A Growth Path to Machine Monitoring and Data Collection

The connections that enable operators to download tool paths and other files can also be used to report machine status automatically as well as streamline manual entries of production results.

Share

Many machine shops have a network in place that enables CNC machine operators to download part programs and other digital files for use on the shop floor. This is the essence of DNC, which stands for direct numerical control, or is sometimes also called distributed or downloading numerical control. This network, however, can also be the basis for machine monitoring and data collection, using the same connections as the DNC system.

PortCNC, a DNC and shop communication solutions provider, sees these extensions as a logical and practical growth path for a DNC system. The company’s eNetDNC is designed to make optional extensions for machine monitoring and data collection reliable and secure. The company also sees inherent advantages to a DNC-first approach to adding these functions. For example, DNC-based machine monitoring can be “event-driven” to provide a timely, detailed view of machine utilization and performance without generating a high volume of data traffic on the network. It also avoids exposure to security threats that are a concern with web-enabled networking. Likewise, data collection can be implemented independently of an enterprise resource planning (ERP) or shop control system so that the software and hardware are not tied to one proprietary provider.

In some cases, the company reports, the value of acquiring machine-monitoring capability and/or data-collection features has compelled shops without a DNC system to put one in as their entry into data-driven-manufacturing concepts.

DNC as Step One

Whether a shop is focused on DNC, machine monitoring or data collection, the primary prerequisite is the functionality of the DNC system—that is, being able to get the CNC program to the machine tool without interruption or loss of data integrity. PortCNC says the chief considerations are flexibility and reliability of the network connections, along with flexible software that can be readily updated.

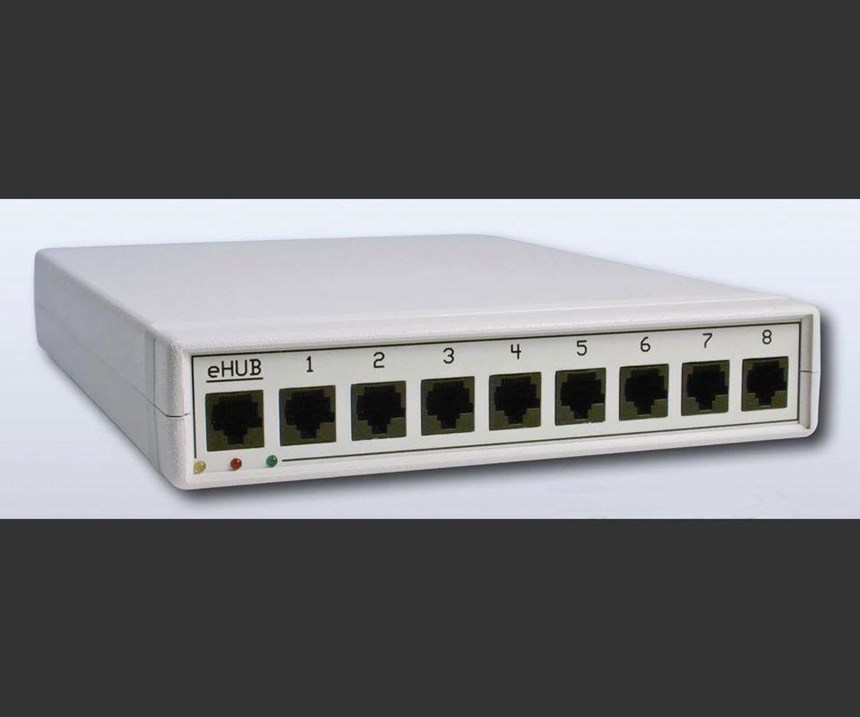

For shops that do not anticipate moving or rearranging CNC machine tools often, the company recommends a hard-wired system that uses Ethernet cable connections. Ethernet is provided on most newer machines; older machines with serial (RS-232) ports can also be connected. Utilizing USB interfaces is another option.

A wireless DNC network works well in an environment in which machines may need to be moved frequently, such as a facility that wants to reconfigure machining cells when production jobs change. Wiring drops and cable strings do not need to be modified with a wireless system. However, great care is needed in locating access points and providing data checking with wireless systems to be sure all data transmissions are complete and accurate. For shops that require very large CNC programs to be transmitted in a drip-feed mode (that is, the receiving control unit can download a file in portions as internal memory becomes available), a hard-wired system is generally more efficient. It is also largely immune to data-transmission discrepancies that require data to be re-sent repeatedly, as a wireless system may need to do to maintain data integrity.

Whether the DNC system uses a hard-wired network or wireless connections, the hardware, such as routers and receivers, must be suitable for the environment of a machine shop. Protection against electrical surges for power losses is also essential.

On to Machine Monitoring

PortCNC adds machine-monitoring capability to its DNC system by having a specially made printed circuit board installed in the electrical cabinet of the CNC and linking it to the DNC network connection. This board and its electrical interfaces are in line with the power circuits so that electrical signals can be detected and reported to the monitoring software. The monitoring board recognizes the signals as indicative of the machine being in or out of cycle (running or not running). Other “events” such as an operator applying a feed rate override can also be detected and reported.

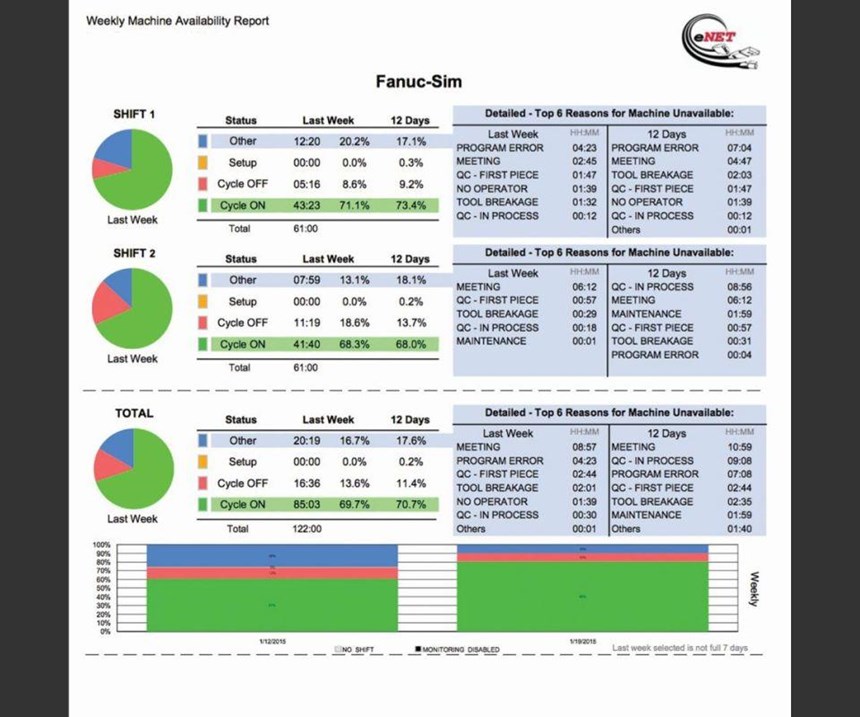

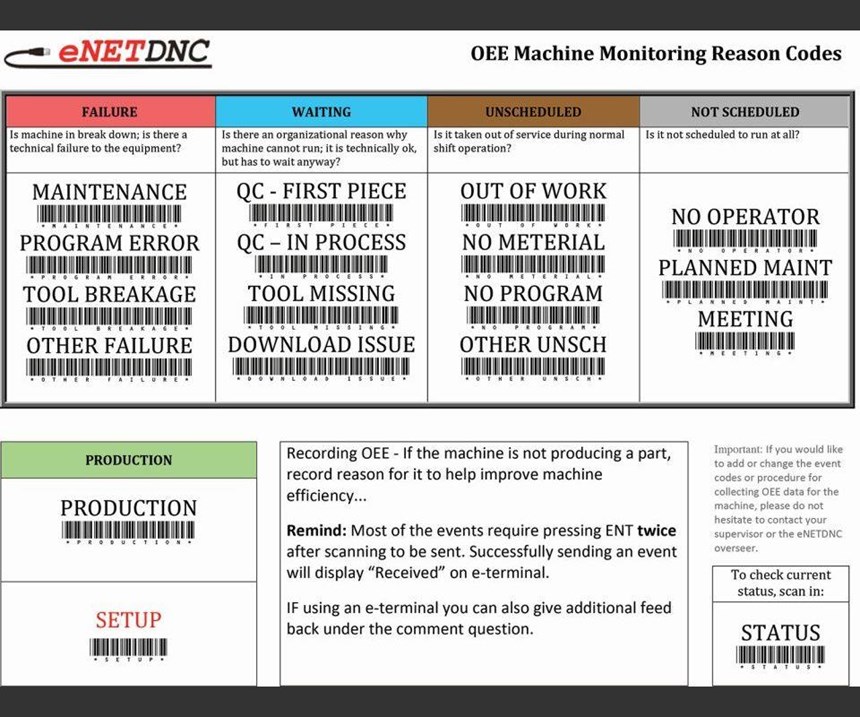

When a machine is not running, the system can be programmed to disable the cycle restart signal until the operator enters a code indicating the reason for the stoppage. This helps ensure that causes of downtime are reported accurately and promptly. Data representing these basic events can be automatically reported to the shop’s monitoring software and then presented as a dashboard on a large-screen display panel on the shop floor, made available on the shop’s computer network, or viewed on mobile devices (when the eNetDNC mobile dashboard feature has been enabled). This data can also be imported into common spreadsheet programs or databases such as Crystal Reports.

This event-driven monitoring system does not require an interface to the machine’s CNC unit, so it does not create data exchangeability or interoperability issues with machines sourced from different builders. In most cases, legacy machines or non-CNC equipment can also be monitored with the installation of the same monitoring board and DNC connection.

According to the company, one major benefit of event-driven monitoring is the light network traffic it creates. Because only the most essential data about the operational status of connected machines is collected and transmitted, there is no data overload or restrictions on transmission speed because of bandwidth limitations. Storing event data in memory can be handled locally at the machine or in a network file server. The shop does not have to resort to storage in the cloud or in added file servers for that purpose.

Using the eNetDNC system for machine monitoring does not require an internet-based network. This sidesteps concerns about data security and possible hacker attacks. As PortCNC points out, the advantages of having real-time machine monitoring and the visibility it gives to shop personnel does not come at the cost of heavy IT department involvement or complex network security provisions.

Adding Data Collection

Production data can be collected at the CNC machine using the same connection as the DNC system. Essentially, what is needed is a means for the operator to enter data and transmit it to a shop management or ERP system. Because data collection is piggybacked on the DNC system, the operator can enter data at his or her work-station rather than having to travel to a remote kiosk or terminal to do so.

Options for data entry from this supplier include a barcode scanner (called an eWand) and a keypad with a message bar (called an eTerminal). The scanner and keypad are designed to work together. Using the scanner can simplify input and improve data quality, while the keypad enables other numerical data to be entered manually.

The data-collection feature of eNetDNC provides a setup screen that enables the user to specify the data to be entered. This screen can be used to match how data is entered with the input requirements of the shop management software or ERP system that it feeds. Because this data-collection feature remains part of the DNC system, it does not have to be replaced or upgraded if the shop changes the shop management or ERP software. If this software is changed, the data fields and entry codes can be re-specified for eNetDNC compatibility.

Data collection via the DNC connection covers key facts about production such as operator ID, job number, cycle time per part, part counts (good parts and scrap parts), codes for part rejects, and notes or comments from the operator.

A Growth Path for Users

Using DNC as a springboard to machine monitoring and/or data collection has the additional advantage of streamlining training for machine operators and shopfloor supervisors, PortCNC says. Users are not asked to learn a new system, but to accommodate new features on the existing DNC platform. The company believes this reduces culture shock and resistance, thus making implementation smoother and less disruptive. Another plus with this DNC-based approach from PortCNC is that shops are not charged maintenance fees for updates and support.

Down the road, if a machine shop decides it wants more details about machine performance, component status or sensor readings, much of the infrastructure and procedural habits will already be in place with the addition of machine-monitoring and data-collection to an existing DNC system. Data from the machine monitoring and data collection features can also be integrated with the new third-party system, depending on how the databases are structured and formatted.

Many manufacturing companies are asking how they can fit into the emerging world of the Industrial Internet of Things or Industry 4.0 that they have been hearing so much about lately. Aspects of these sweeping changes can be intimidating and futuristic. Recognizing that a capable, functioning DNC system provides a head start toward the most promising benefits of data-driven manufacturing should ease these anxieties and encourage manageable, affordable steps in that direction.

Related Content

Shop Quotes Smarter, Works Harder with Machine Monitoring

Temco first installed MT-LINKi to optimize quoting. Now, the software helps the shop optimize its machines — and machine purchases.

Read MoreCan Connecting ERP to Machine Tool Monitoring Address the Workforce Challenge?

It can if RFID tags are added. Here is how this startup sees a local Internet of Things aiding CNC machine shops.

Read MoreProtecting Your Automation Investments

Shops need to look at their people, processes and technology to get the most of out their automation systems.

Read More5 Stages of a Closed-Loop CNC Machining Cell

Controlling variability in a closed-loop manufacturing process requires inspection data collected before, during and immediately after machining — and a means to act on that data in real time. Here’s one system that accomplishes this.

Read MoreRead Next

5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More