Share

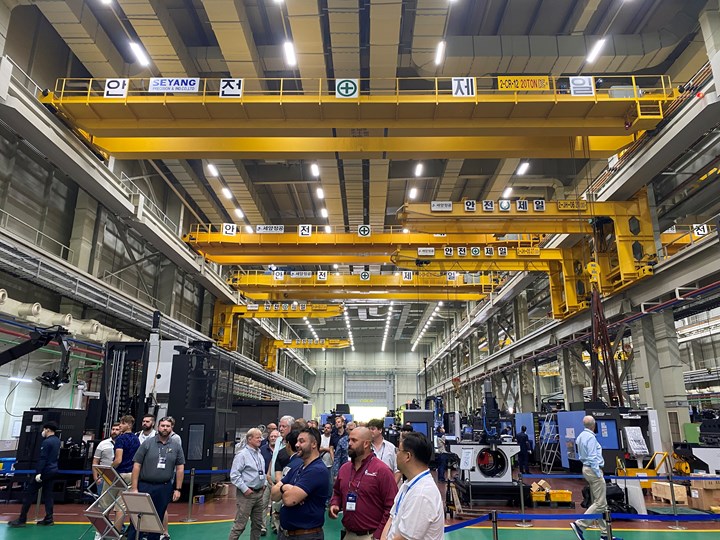

The 14th DN Solutions International Machine Tool Fair (DIMF) took place June 5-8, 2023. The show included demonstrations of machine tools, automation systems and other manufacturing technologies at the Busan Exhibition and Convention Center (BEXCO) in Busan, South Korea.

A lot has changed since the last in-person Doosan International Machine Tool Fair (DIMF) four years ago. The world has been through a global pandemic and is still dealing with the aftereffects in the form of supply chain disruptions and economic fluctuations. And Doosan itself has been through some major changes: in 2022, DTR Automotive purchased Doosan Machine Tools to create DN Group, consisting of DN Automotive (formerly DTR Automotive) and DN Solutions (formerly Doosan Machine Tools).

DIMF also included additional demonstrations at DN Solutions’ Seongju factory in Changwon, South Korea. Attendees were able to see a total of 65 machine tools (40 of which were new) across the two locations.

With these changes comes new technology and new business decisions. I was able to discuss these changes with DN Solutions President WJ Kim at the 2023 edition of DIMF, which included a showcase of machining technology at BEXCO in Busan, as well as a tour of the company’s Seongju factory in Changwon with additional demonstrations from larger machine tools. Read on to learn how DN Group is responding to the automotive industry, labor shortages, supply chain disruptions and sustainability, as well as how the company is working to support the U.S. market.

Conversation has been edited for length and clarity.

DN Solutions President WJ Kim welcomes attendees to DIMF 2023 at BEXCO. Photo Credit: DN Solutions

Modern Machine Shop

In 2022, DTR Automotive purchased Doosan and then created DN Solutions and DN Automotive. Can you tell me how DN Solutions fits into the DN Group's overall business?

WJ Kim

DN Automotive, the mother company, formerly DTR Automotive, is very specialized in antivibration systems for automotive, and we have a long history in the automotive industry globally. This antivibration system is a very technically intensive product. So, we are very keen on developing R&D capabilities to properly and fully develop such products. The automotive industry is one of the key consuming markets in the machine tool industry, but otherwise there is no major relationship between the two industries. To diversify our business portfolio a bit, we decided to acquire DN Solutions. The automotive industry continues to bring plenty of opportunity, but who knows what will happen in the future. We have been looking for a new business area which gives us some additional growth opportunity for the future and to which we can add value.

We set three main criteria when going through the selection process. One is that we like to be a global business, a global player. At DN Automotive, almost 93% of our revenue comes from outside of Korea, like General Motors, Stellantis, BMW, and other global-oriented companies. Two, we wanted a global player that was technology-centric, technologically intensive. With our R&D capability, we don't like to be a commodity player. That's why R&D is critical. And finally, manufacturing is very deep in our DNA. We did market studies for several new potential acquisitions, but it turned out that none of them fit our DNA. Based on those three criteria we finally found Doosan Machine Tools, now DN Solutions, was the best fit for us. Looking at DN Solutions as a machine tool business, we are pretty well balanced. One of the biggest key industries for machine tools is automotive. Thirty percent of our total revenue at DN Solutions comes from the automotive industry.

DN Automotive has very deep knowledge and expertise in the automotive industry, so we can anticipate some synergy between the two companies. We see a few examples of how we expect some potential synergy.

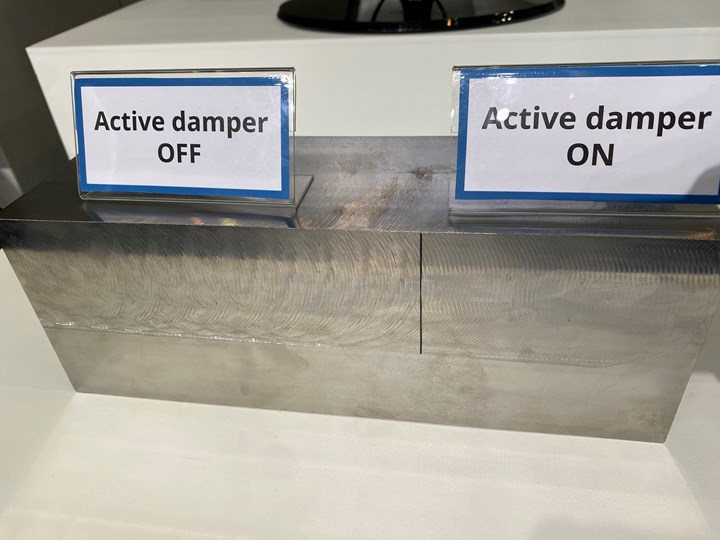

One is on display here at DIMF, within some of our new product offerings. Newly applied for DN Solutions CNC machines, we have used a DN Automotive-developed technology for canceling vibration. The technology uses active damping to reduce vibration. I asked the DN Solutions and DN Automotive R&D teams to sit down together and find a way that we can collaborate. The result? They modified this active damping technology for machine tools and it has provided pretty impressive benefits to the product lines.

The second shared synergy is that there's a lot of automotive expertise inside of DN Automotive. They know about the future trends for OEMs. I asked both teams to sit down together to share that technology outlook and expertise as well. From our annual internal technology market research report on the DN Automotive side, we have shared the technical analysis with DN Solutions. These synergies have already benefited us in developing very good new products. We’re more competitive, more adaptable to automotive as a whole.

In 2022, DTR Automotive (now DN Automotive) purchased Doosan Machine Tools (now DN Solutions). DN Solutions is able to leverage DN Automotive’s industry knowledge in a number of ways, including adapting its antivibration systems for automotive to create an active damper for reducing chatter in machining.

Modern Machine Shop

Especially with automotive being your biggest end market.

WJ Kim

Sure. DN Automotive is, as I said, a global company. We are operating in nine locations: of course Korea, China, UK, Italy, Poland, Germany, Brazil, Mexico, America. The top leadership from DN Solutions America came to me and said, we need to do something better in Mexico, like a parts center, a client support or technical center. DN Automotive has a very big facility in Mexico. We built up our parts center and service center within just one month after we made the decision. And the same in Detroit. We opened up a satellite technical office inside of DN Automotive. We already have plans in the works or have completed additional locations for DN Solutions America in Mexico, Detroit and Chicago. We know how to be present where customers and distributors need us.

Modern Machine Shop

The US and other countries are experiencing a shortage of skilled workers and a trend is manufacturers looking to automation to try and fill that gap. What automation solutions does DN offer?

DIMF included a whole area dedicated to automation solutions, including pallet changers, cobots and AGVs (autonomous guided vehicles). As a machine tool company, WJ Kim says DN Solutions aids automation efforts by building machine tools that can run 24/7 and developing software to ease implementation and enable machine monitoring.

Photo Credit: Ivor Andrew

WJ Kim

Our ultimate goal is to make our machine tools operate unmanned for 24/7 operation. But we cannot do everything by ourselves, in terms of automation.

Once a job shop or automotive company decides to implement automation, their next step is that they want to run the machine for 24 hours. What does that mean? From the beginning of product development, we have to consider how we can make the machine itself better, more robust, more solid in terms of durability, reliability, serviceability, even availability. That's from a machine tool perspective.

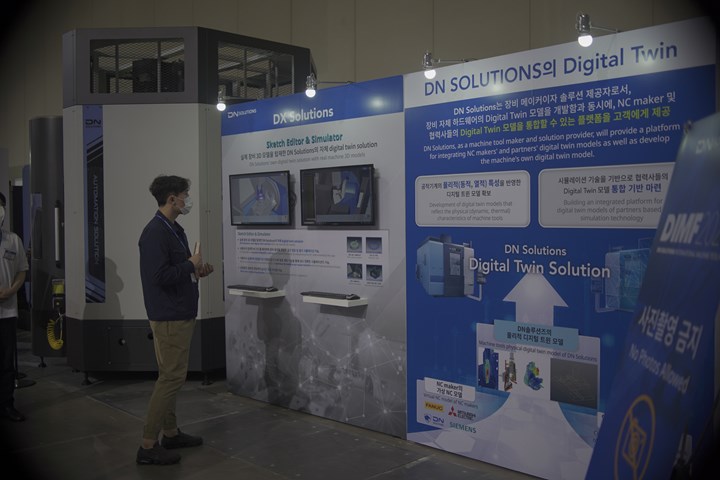

Once we decide to implement an unmanned operation, we have to monitor the system remotely. We are very interested in developing new technology based on digital twins. We'd like to make a machine tool a platform to support client automation. We already developed an operating system called CUFOS, Customer User Friendly Operating System, which is PC-based. On top of that, we’d like to build an API for other kinds of collaboration with robotic companies, so they can easily implement software and hardware together with DN Solutions. We are keen on developing an ecosystem that provides comprehensive solutions for automation and a total system approach.

DN Solutions is developing digital twin technology that will not only aid in lights-out machining, but could also save energy by preventing crashes and other issues that require unnecessary energy and effort to fix. Photo Credit: Ivor Andrew

Modern Machine Shop

Can you talk about how DN Solutions is thinking about sustainability in manufacturing?

WJ Kim

Sustainability is a key to our future. Of course, saving energy is critical. But my view is to improve reliability at the same time. Twenty-four hours of operation without downtime is also a way to save energy. If the machine itself crashes, we have to spend unnecessary energy and effort to fix it. That's why we will continue to further invest in developing monitoring systems and digital twins. If we can implement sophisticated digital systems, they can do things digitally with no energy consumption. We have also developed a mist-free solution for oil mist purification which minimizes motor power, resulting in reduced power and maintenance costs. These may be small examples of what we are doing; however, they are good ways to get there. That’s my view on sustainability. I like to start with small things you can do and keep building.

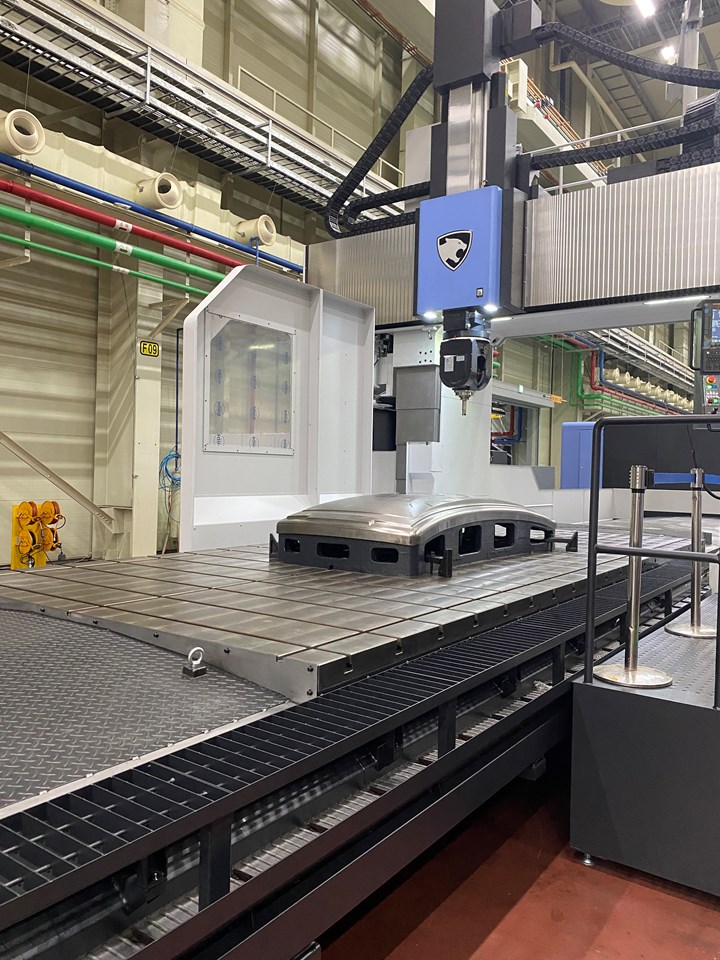

As new electric vehicles are developed, new opportunities will arise for machine tool builders such as DN Solutions, and the company’s partnership with DN Automotive gives it valuable insight into the future needs of automotive OEMs. This roof punch, shown on a DCM 3160H double-column machining center, offers an example of an automotive part.

Modern Machine Shop

Yeah, exactly. I think people, especially job shops, need small things that they can do and think about and it'll be a good starting point for them. We've talked about automotive a lot already, but can you talk about how the DN Group is responding to all of the changes in the automotive industry with it going electric?

WJ Kim

The electric vehicle itself is evolving. DN Automotive’s vibration management system partly is to cancel the vibration on the engine. Looking deep into the ICE automobile, there are between 55 and 60 vibrating components, like the engine mount, body mount, tire mount, suspension bushing, and many more. Inside electrified vehicles, the number of parts is increased to between 60 and 65 on average. Why? As ICEs go away, more motors come in. So maybe we can provide some kind of a motor mount.

Also, drivers can get very sensitive about noises coming from the road outside. The engine usually cancels it, as the engine noise is much louder. But as it goes away, they hear noises coming from the road. That means that we need more sophisticated, more high-quality mounts to cancel that noise. Having said that, as EVs evolve, DN Automotive is a big beneficiary.

How about the machine tool industry? As I said, the automotive industry represents 30 percent of our total revenue, and as the engine goes away, yeah, it is true that we lose the opportunity on the machining for the engine side. But there are a lot of small, very precise machining solutions needed to develop to produce EV motors. What about the battery? The battery pack, battery case is very critical, right, same problem. It offers us additional opportunities.

Modern Machine Shop

Can you talk about the U.S. market and how that fits into DN Solutions as a global company?

WJ Kim

The US market is our number one market for sales. For many machine tool companies the US market is number one. It offers us great growth opportunity. Our ultimate goal is to be a top, global, technology-based manufacturing solution leader. That means that we need to have the capability to be a total systems provider. There are many different sets of clients in America. Job shops may have different requirements than big enterprise clients. America is also a core part of our business in terms of geography. That's why we decided to build up our own technical center in Chicago. But the center must be differentiated from our partners. We’ll have technology specific for target industries. Like in America now, a lot of the big demands are coming from the semiconductor, IT, medical and electrified vehicle markets.

And just to elaborate a little bit further, differentiating from our partners, meaning our distributors, because they're excellent with the service, but what value add can we give to the customer? We want a place where machine tools really are hands-on, where we can connect our customers with other customers and set up solutions that are maybe otherwise scary to some machine shops. Automation, like pallet pools, or remote monitoring through MTConnect with iDooCare and that type of thing might seem scary or out of reach to a new user. Those kinds of things might seem a little more achievable when a customer can come see it in action at the OEM’s facility. We can show them, train them and let them come back as often as they’d like. Maybe some of that evolution of automation and AI and things like that is not scary anymore. That’s just a part of the technical center we are building in Chicago and other locations in North America.

We have hired some of the leaders for the tech center. And we are now in the middle of the process to hire another four. And because collaboration between America and Korea is quite crucial, I plan to send some proven, talented engineers from Korea to America. Accessibility to the professionals who really are building and designing the machine tools and technology, and bringing that intelligence to the U.S is a big change for us. But it's the right direction for a solutions provider. So we're excited for that.

Modern Machine Shop

Do you have an estimate for when the tech center will be open?

WJ Kim

We are lucky because we found a very nice building. We need to renovate. I cannot say exactly, but my plan is to open up to people next IMTS.

Modern Machine Shop

Reshoring is a big trend in manufacturing in every country. Can you talk about how it's affecting DN Group both as a manufacturer of automotive parts and as a supplier of manufacturing equipment?

WJ Kim

Yes, reshoring. We’ve seen many different perspectives. On the machine tool side, we are very aggressively developing a local supply chain inside Korea. That’s one way to prevent any potential challenge to us. That's our number one action we’ve taken to prepare for reshoring.

It can give us opportunities, especially on the automotive side, because we have a very nice facility located in Mexico. So Mexico is now working to supply key components to the Americas, especially to automotive manufacturers.

Of course, we also have an eye on what reshoring means to the customers, so we’ve drastically increased inventory in the US so that they can be responsive to their production requests.

Modern Machine Shop

What are some challenges to doing business in the US, and opportunities that you see in the U.S. market?

WJ Kim

Of course, it's a mixed opportunity. A lot of big Korean companies like Samsung, LG and SK are rushing to America to build up battery and semiconductor manufacturing. Samsung invested a lot of money to build up a semiconductor plant in Austin. Now, it's not only Korean big companies, we also see that there are a lot of big movements in America to making semiconductors and electrified vehicles. We are very good at developing new machines that are very, very, very compatible for the semiconductor industry because we have Samsung, we have SK, we have a lot of experience to work with. Same for the battery. Same for electrified vehicles. Of course, there is a risk with export control.

Conclusion

Evidence of all of these changes was visible across DIMF. The Bexco exhibition included demonstrations of the vibration damping technology developed with DN Automotive, a variety of forms of automation (including AGVs, pallet changes and cobots), solutions for machining semiconductor materials (such as grinding and laser cutting machines) and digital solutions (Smart Thermal Control software to calculate thermal displacement; new functions for the CUFOS control including table balancing, power consumption monitoring, tool management and sketch cycles; digital twins; and iDOOCare machine status monitoring and maintenance). Machining applications for the automotive industry were also among the demonstrations at the Seongju factory, showing larger machines for making dies and molds.

Related Content

Solve Worker Shortages With ACE Workforce Development

The America’s Cutting Edge (ACE) program is addressing the current shortage in trained and available workers by offering no-cost online and in-person training opportunities in CNC machining and metrology.

Read MoreHow I Made It: Amy Skrzypczak, CNC Machinist, Westminster Tool

At just 28 years old, Amy Skrzypczak is already logging her ninth year as a CNC machinist. While during high school Skrzypczak may not have guessed that she’d soon be running an electrical discharge machining (EDM) department, after attending her local community college she found a home among the “misfits” at Westminster Tool. Today, she oversees the company’s wire EDM operations and feels grateful to have avoided more well-worn career paths.

Read MoreWorkholding Fixtures Save Over 4,500 Hours of Labor Annually

All World Machinery Supply designs each fixture to minimize the number of operations, resulting in reduced handling and idle spindle time.

Read MoreAddressing the Manufacturing Labor Shortage Needs to Start Here

Student-run businesses focused on technical training for the trades are taking root across the U.S. Can we — should we — leverage their regional successes into a nationwide platform?

Read MoreRead Next

Doosan Machine Tools Changes Name to DN Solutions

The company, under the leadership of its parent company, DN Automotive, will be reborn as a total manufacturing solutions provider through identifying and investing new growth opportunities.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read More

.jpg;maxWidth=300;quality=90)