Anca MX7 Linear Increases Taylor Toolworks' Grinding Flexibility

Anca’s MX7 Linear tool grinder gave Taylor Toolworks the power and flexibility to create large-diameter carbide tooling and meet the needs of many tooling markets.

Share

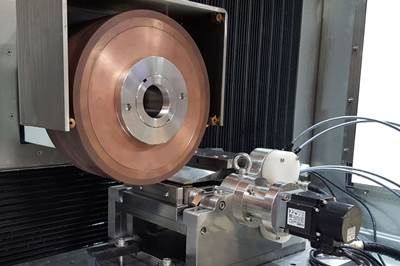

Taylor Toolworks President Jesse Taylor says the MX7 Linear from Anca has given his shop the power and flexibility to target the large-diameter carbide tooling market.

Any shop that aims to meet tooling needs for applications ranging from woodworking to aerospace to general machining and cutting of plastics requires versatility. Taylor Toolworks, a manufacturer and service provider of cutting tools based in Alberta, Canada, says it has found the right technology to stay at the forefront of its market with Anca’s MX7 Linear tool grinder.

Taylor Toolworks, which president Jesse Taylor runs with his sister Kristyn, uses five-axis CNC grinding and fine micro-grain carbide products to maintain the mirror finishes and exacting tolerances needed for high-performance tooling. The shop provides reconditioning services and produces end mills and custom tooling.

Meeting Specialized Needs

Solid carbide end mills are just one of the many types of cutting tools produced at Taylor Toolworks.

Taylor Tookworks’ reconditioning services consist of tool regrinding, recutting and recoating. Its end mills include super-polished flutes, special-grade carbides and performance-enhancing coatings. The custom tooling selection caters mainly to the woodworking and metal industries, with micro-grain carbide inserts, custom profile tools, step drills and other options.

When Taylor Toolworks began to move into the large-diameter carbide tooling market, focusing on tooling with diameters ranging from 1.000 to 1.500 inches, it found that it required greater manufacturing versatility. Taylor had seen Anca machines at trade shows, and initial conversations with Anca application specialists about the MX7 Linear tool grinder caught his attention. Anca’s swift lead times, which were much faster than the “six months to a year” timeline Taylor observed with other machine tool builders, further helped him make a decision.

Versatility and Power

The MX7 Linear’s 38-kw (51-horsepower) spindle provided the power Taylor Toolworks needed to tackle large-diameter tool manufacturing. Other features that helped the company achieve high-output, high-precision manufacturing include standard linear scales on the X and Y axes, Anca LinX linear motors for X- and Y-axis motion, an integrated wheel dresser, and automation options, which include the RoboMate or FastLoad-MX compact loader. The machine is designed to accommodate varied batch sizes with minimum setup time. Anca recommends the MX7 Linear for high-volume production of tools ranging to 25 mm (1 inch) in diameter.

Anca’s MX7 Linear tool grinder also includes a standard six-station wheel changer that stores and changes up to six wheel packs. Taylor particularly credits this feature for helping with rapid setup and flexibility, with the versatility of six-wheel packs “essential” to machining complex geometries like step drills and porting tools with multiple grinding operations. The MX7 Linear’s cylindrical linear motor design also increases reliability to improve the quality of the surface finish.

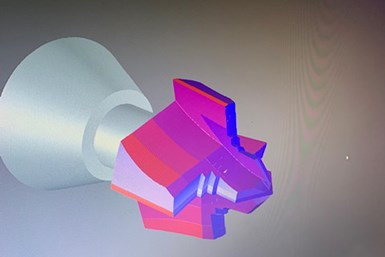

Anca’s tool simulation software enables Taylor Toolworks to virtually program tools before they are processed on the MX7 Linear.

Taylor also credits Anca’s tool simulation software in his purchasing decision. This software, part of Anca’s ToolRoom software package, allows the shop to virtually program tools on desktops or laptops before processing them on the actual machine. Taylor notes that carrying out these simulations “saves valuable machine time” that allows the shop to stay competitive. The ToolRoom software provides specific applications for each tool produced at Taylor Toolworks, such as a step tool editor and a profile tool editor.

In addition to step drills, Taylor says the shop produces through-coolant drills and form tools on the MX7 Linear. Whenever service issues arise using the MX7 Linear — or any of Taylor Toolworks’ three other Anca machines — Taylor says Anca has done well at solving them, whether through a phone call or an on-site visit.

Related Content

Ballbar Testing Benefits Low-Volume Manufacturing

Thanks to ballbar testing with a Renishaw QC20-W, the Autodesk Technology Centers now have more confidence in their machine tools.

Read MoreThe Future of High Feed Milling in Modern Manufacturing

Achieve higher metal removal rates and enhanced predictability with ISCAR’s advanced high-feed milling tools — optimized for today’s competitive global market.

Read MoreOrthopedic Event Discusses Manufacturing Strategies

At the seminar, representatives from multiple companies discussed strategies for making orthopedic devices accurately and efficiently.

Read More5 Tips for Running a Profitable Aerospace Shop

Aerospace machining is a demanding and competitive sector of manufacturing, but this shop demonstrates five ways to find aerospace success.

Read MoreRead Next

New Applications for Electrochemical Grinding

With advances in control, sensor and automation technology, electrochemical grinding is more accurate and productive than ever, opening up new applications for the traditionally niche process.

Read MoreChoosing The Right Grinding Wheel

Understanding grinding wheel fundamentals will help you choose the right wheel for the job.

Read MoreReducing Chatter with 'Weird' End Mills in CNC Machining

ANCA’s ToolRoom RN34 software improves CNC productivity through the intuitive grinding of complex end mill geometries for aerospace, die mold and power generation.

Read More