Share

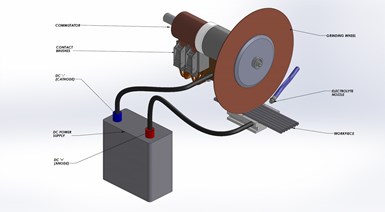

The ECG process requires a DC power supply, a conductive grinding wheel (typically composed of abrasive, copper and a resin binder), electrolyte fluid (commonly sodium nitrate) and a workpiece made of material that’s both conductive and reactive, such as steel, stainless steel, chrome-nickel alloy or high-temperature alloy.

Although it has experienced a steady growth, electrochemical grinding (ECG) is mostly known as a niche process. Developed in the 1930s, it became popular in the US in the 1950s for grinding carbide cutting tools. At the time, the only other way to grind carbide was with an expensive, natural diamond grinding wheel. ECG has the ability to grind difficult-to-cut materials such as carbides, and this process became popular for producing cutting tools. But as disposable tooling inserts and molded near-net tool shapes were developed, ECG dropped off in popularity. Now, it’s mostly known in applications that work with challenging materials and thin-walled, fragile workpieces, including tubing cutoff, medical devices and parts for aircraft engines.

But according to Tom Travia, VP of Business Development at ECG equipment supplier Tridex (a Glebar company), potential applications for the process are again increasing as the technology advances. Today’s ECG provides an increasingly efficient option for machining challenging alloys, and OEMs in sectors such as medical see it as an effective way to machine precise components in these materials.

What Is Electrochemical Grinding?

ECG is a hybrid process combining electrochemical machining and grinding.

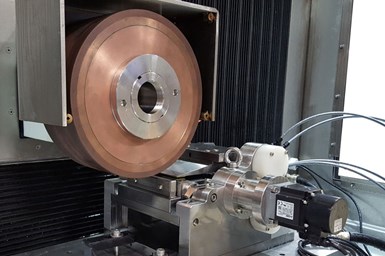

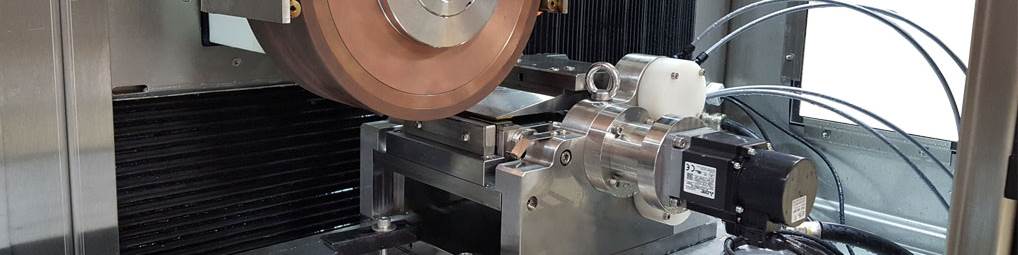

In electrochemical grinding (ECG), the workpiece becomes an anode and the grinding wheel becomes a cathode, removing material from the workpiece both electrochemically and mechanically.

Electrochemical machining is an electrolytic operation where the workpiece becomes an anode and the cutting tool (in the case of ECG, a grinding wheel) becomes the cathode. When a direct current flows between the anode and the cathode, it creates a reaction that’s similar to electroplating, but instead of taking material from the anode and depositing it onto the cathode, the material is removed from the anode and washed away in the electrolyte fluid. ECG takes electrochemical machining a step further by cutting the metal mechanically with the grinding wheel while simultaneously dissolving the material electrochemically. “The theory is that you can reduce the hardness of the material and partially decompose it as you're grinding, so that the grinding wheel is cutting with much lower force,” Travia explains.

In some ways, ECG is similar to conventional grinding — some of the same rules apply. For example, programming and setup work much the same way. Workholding is also very similar, the only differences being that fixtures for ECG need to be made of corrosion-resistant material and allow electrical contact with the workpiece. “There are things that are a little bit different than traditional grinding,” Travia says, “but if somebody is experienced at grinding, they would very quickly pick up the differences.” He adds that it’s common for Tridex customers to have no grinding experience at all when adding their first ECG machine.

The process requires some special equipment, including a DC power supply. It also requires a conductive grinding wheel. A standard ECG wheel is composed of abrasive (such as CBN, diamond, aluminum oxide or silicon carbide), copper and a resin binder. Binders and grit sizes vary based on the application. The grinding wheels Tridex uses range in size from 0.004 to 4.0 inches wide. These standard wheels will work for most applications, although workpiece materials such as copper or titanium will require wheels made for these materials.

Electrolyte fluid is an important part of the ECG process. It’s sprayed over the grinding wheel and workpiece, similar to coolant. But according to Travia, its function is very different. While it does have some cooling properties, ECG doesn’t generate much heat, so the goal isn’t to flood the process with as much fluid as possible, like in other machining operations. “The electrolyte is part of the process, meaning if you change the flow rate of the electrolyte, it's going to impact the way the cut comes out,” he explains. The process therefore requires maintaining a specific flow of electrolyte fluid to ensure the cut is burr-free and within tolerance. “There are some things that go into that, more so than just turning a valve,” he adds. “The flow is an important variable in ECG.” The electrolyte fluid itself is essentially a variety of salt water. Sodium nitrate is typically dissolved in this fluid because it’s not too corrosive, it’s mild enough that operators can work with it, and it’s cost-effective. Like any other metalworking fluid, the electrolyte gets contaminated with metal, so it needs to be filtered and eventually changed out and disposed of properly. “Typically our machines have a centrifuge for filtration so you can get as much fine particulate out of it as possible,” he says. “That'll usually extend the life of the electrolyte quite a bit, in some cases double.”

ECG can only be performed on workpieces made of conductive materials. This includes a wide range of materials including tool steels, stainless steels, most chrome-nickel alloys and high-temperature alloys. In addition to being conductive, the material must be electrochemically reactive. For example, although platinum is conductive, it’s not electrochemically reactive enough for ECG.

Benefits of Electrochemical Grinding

ECG has a number of benefits over grinding and other forms of machining. The electrochemical process reduces cutting forces, extending wheel life and eliminating the need for dressing. And because ECG does not leave burrs or a recast layer on the workpiece, it can eliminate secondary operations.

One of the biggest benefits of ECG is that the electrochemical process can oxidize workpiece material regardless of hardness, and reduce the force required to cut it. This means that ECG processes have longer wheel life than traditional grinding processes. According to Travia, G ratios (the ratio of how much metal is removed to how much wheel is consumed in doing so) of traditional grinding applications are usually 1 or less than 1, while G ratios for ECG applications can range from 20 to well over 100.

ECG also has the ability to easily cut difficult-to-machine materials. That’s because these materials, which include chrome, cobalt and nickel, are highly reactive and dissolve easily in the electrochemical process. Alloys with high proportions of these materials, such as Inconel, Hastelloy and Waspaloy, cut freely with ECG, but pose challenges in conventional machining. “When you take a piece of carbide into Inconel, for instance, you have to cut slowly, you don't get very good tool life, and it's subject to work hardening,” Travia says. “It's not easy to machine, but it is it is for electrochemical grinding.” ECG can also machine more common materials, including aluminum and copper, but it’s not always the most cost-effective solution. “It's easy to cut aluminum a lot of ways,” he notes.

ECG cuts materials at relatively low heat, as opposed to processes that operate at high heat, such as EDM and laser cutting. The rapid heating and cooling of the material in those processes potentially causes metallurgical changes that can work harden the material and make secondary operations (drilling and tapping a hole, for example) difficult. It also tends to leave a heat-affected zone, or recast layer, that’s prone to cracking. This is a common issue in tube cutting, especially for aircraft engines. These tubes are often flared at the end so fittings can be added. If it has a recast layer, it could crack and lead to the scrapping of an expensive part at the end of the production process. The recast layer can be removed, but doing so adds a step to the process.

Another benefit of ECG is that its grinding wheels don’t require dressing. Because the electrochemical process softens the workpiece material and the electrolyte fluid washes some of it away, the material doesn’t get packed into the wheel like it does during traditional grinding processes. “Consequently, your wheel may cost more initially, but it's going to last much longer,” Travia says. It also means that ECG is faster than conventional grinding processes, particularly ones that require continuous dressing, such as creep-feed grinding. Although the wheels last longer, they don’t last forever—they get smaller, and form grinding wheels will eventually lose their shape, requiring re-truing.

ECG can also eliminate a number of secondary processes. It doesn’t leave burrs, and while EDM and lasers can also cut burr-free, ECG provides a slight edge break and good surface finish.

Uses for Electrochemical Grinding

Despite its reputation as a niche process, ECG has a wide range of potential

Because ECG can easily cut high-temperature alloys, it’s commonly used in the aerospace industry. Use of ECG is also growing in the medical industry, for production of parts such as hypodermic needles and this arthroscopic shaver.

applications. Travia says that when determining whether or not ECG is a good fit for an application, the first question to ask is, “Can a grinding wheel create the shape you need?” If it can, it’s worth looking into ECG. The process can replace many conventional grinding applications, including conventional form grinding. “ECG can remove a lot more metal a lot faster than conventional grinding, in most cases, and with much better wheel life,” he says.

Travia says that when determining whether or not ECG is a good fit for an application, the first question to ask is, “Can a grinding wheel create the shape you need?” If it can, it’s worth looking into ECG.

ECG can’t replace all machining and grinding operations. It doesn’t make sense for applications that require large amounts of material removal, including many milling, turning and surface grinding processes. “If you increase the size of the cut, you increase the amount of current needed in your power supply,” Travia explains. “We normally don’t make power supplies above 1,000 amps, and 1,000 amps is a pretty big cut.”

Two of the most common end markets for ECG are medical and aerospace. Although part geometries in these two fields can be very different, they use many common materials, especially high-temperature alloys, which ECG can cut easier than traditional machining methods. These fields also tend to have thin-walled, fragile parts, such as needles and honeycomb forms, which ECG excels at machining.

One of ECG’s biggest growth areas is in grinding needles for the medical space, including hypodermic needles, surgical needles, trocars and biopsy needles. Conventional needle grinders leave burrs that must be removed by grit blasting or electropolishing. However, these processes dull the tips of the needles. “It wouldn't be very pleasant to have an injection with a dull needle,” Travia says. ECG can be used to grind the bulk of the needle efficiently, with parameters then adjusted at the end to create a sharp tip without large burrs.

Another growth area for ECG is tubing cutoff. With standard fixtures, Tridex’s ECG machines can cut tubes and wire ranging from 0.010 to 3 inches in diameter. Applications for these tubes range from hypodermic needles to smaller tubes in aircraft engines.

Advances in ECG Technology

Like other machining processes, ECG technology has advanced in recent years. “We want to be able to control all the variables in the process to the greatest extent possible,” Travia says of Tridex’s strategy. Control systems in general have improved, making this machining process, like others, more accurate and repeatable.

Electrolyte management has also improved in recent years. “We're able to control the flow better,” Travia says. “We're able to monitor the various parameters of the electrolyte. We can get better control and adjust the cutting parameters as the electrolyte changes.” For example, as the solution gets used, it absorbs metal and becomes more conductive, possibly impacting the cut. Sensors can now measure the amount of salt dissolved in the solution and how conductive it is, as well as flow, temperature and pH. Tridex machines also use a methodology to determine when to change the solution, a decision users previously made without as much technical basis.

Tridex’s acquisition by Glebar has also enabled the company to explore automation. Glebar has been automating its guidewire and centerless grinding machines for some time, and Tridex is applying this experience to its own products. “Now that we're one company, we're starting to find all sorts of applications for automation,” Travia says. The company now offers electrochemical grinders with pallet shuttles, which enable users to load and unload parts while the machine is working. This reduces load time, sometimes to zero. According to him, “That's been pretty well received because it allows for significant improvements in productivity.” In one instance, a customer that was getting 30 parts per hour on a conventional ECG was able to increase throughput to 100 parts per hour on a pallet shuttle machine, without changing anything else. Users can take the pallet shuttle system a step further by adding a robot to load and unload the machine. Tridex is also developing an automation system for its point-grinding machines, which will include a machine-tending robot.

Related Content

4 Commonly Misapplied CNC Features

Misapplication of these important CNC features will result in wasted time, wasted or duplicated effort and/or wasted material.

Read More6 Machine Shop Essentials to Stay Competitive

If you want to streamline production and be competitive in the industry, you will need far more than a standard three-axis CNC mill or two-axis CNC lathe and a few measuring tools.

Read MoreHow to Choose the Correct Measuring Tool for Any Application

There are many options to choose from when deciding on a dimensional measurement tool. Consider these application-based factors when selecting a measurement solution.

Read More4 Steps to a Cobot Culture: How Thyssenkrupp Bilstein Has Answered Staffing Shortages With Economical Automation

Safe, economical automation using collaborative robots can transform a manufacturing facility and overcome staffing shortfalls, but it takes additional investment and a systemized approach to automation in order to realize this change.

Read MoreRead Next

Grinding Cell Automates, Consolidates Surgical Shaver Machining

Pre- and post-grind inspection stations and the right centerless machine enable this robot-tended medical manufacturing process to correct itself.

Read MoreDeciding to Specialize as an Aerospace Supplier

Formerly a job shop serving a diverse local customer base, IPG responded to industry changes by transitioning into becoming an aerospace supplier. Here are the steps the shop is taking to make that change, including adding equipment and implementing plans for quality and marketing.

Read MoreMachine-Tending Automation Gets a Head Start

Making industrial robots more versatile without sacrificing speed or power stretches integration investments and attracts new business.

Read More

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=970;quality=90)