A Third Class of Touch-Trigger Probes

Fully digital probes are especially effective at accurate digitizing routines using a long stylus.

Share

Machine-tool touch-trigger probes are helpful in a number of ways. These probes enable machines to perform automated fixture alignment to speed setups, measure part features for in-process inspection, and even digitize parts for reverse-engineering purposes.

Until recently, there have been two general classes of touch-trigger probes for machine tools: kinematic and strain-gage. Kinematic probes use a spring-loaded mechanism that secures the stylus. This mechanism also contains a set of contacts with an electrical circuit that triggers a probe output when the stylus deflects after touching the part. (The amount of stylus deflection before triggering is known as pre-travel.) Strain-gage probes have a similar spring-loaded mechanism, but use multiple strain gages to trigger a probe output instead of contacts.

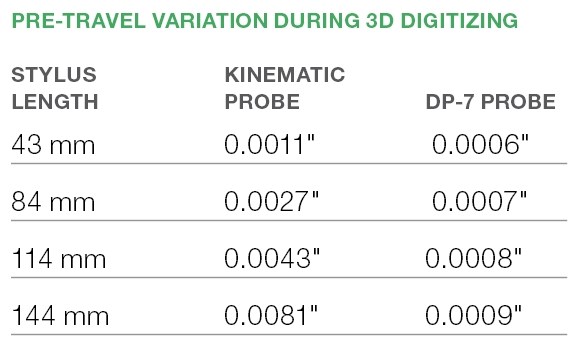

Keith McCulloch says an issue with kinematic probes (and to a lesser extent with more costly strain-gage probes) is measurement error due to pre-travel variation, or “lobing.” Mr. McCulloch is applications engineer for Centroid, a manufacturer of five-axis machines for cylinder head porting, four-axis machines for engine block work and CNCs for retrofit applications. He explains that during 3D digitizing, for example, lobing occurs because the force required to trigger a kinematic probe differs depending on the geometry of the part and the direction that the probe approaches a part. In addition, lobing error becomes greater as stylus length increases, reducing measurement accuracy and introducing distortion to the data when probing deep into part features such as engine block cylinders and cylinder head intake and exhaust ports.

As a result, Centroid has developed what it calls a third class of touch-trigger probes—fully digital probes. (The company has manufactured kinematic probes for more than 20 years for use with its cylinder-head-porting machine package.) The solid-state triggering functionality of the company’s DP-7 probe provides uniform triggering in all axes and 1-micron unidirectional repeatability. Mr. McCulloch says that with a 40-mm stylus, the DP-7 is twice as accurate as a conventional kinematic probe for 3D digitizing. However, he notes that the performance differences really diverge with long styli. With a 140-mm stylus, the DP-7 delivers ten times the accuracy than the kinematic probe, Mr. McCulloch says (see Table 1 to the left). For digitizing applications that require long styli, such as cylinder head port duplication and machining, more accurate probing data means less time is required to clean-up extraneous measurement points to establish an accurate model. So while the DP-7 isn’t faster than kinematic probes at probing routines for such applications, the overall digitizing process takes less time because there’s minimal data clean-up.

Mr. McCulloch adds that the DP-7’s digital design not only is inherently shock- and vibration-resistant, but also contributes to an affordable price point that may entice more machine shops to take advantage of on-machine probing. The probe can be used on virtually any machine tool brand, too. A machine’s CNC requires only a PLC probe input and software that supports probing routines. Probe signal transmission and power is achieved via a cable that plugs into a bulkhead connector wired to the machine’s control. Although the probe must be manually plugged in, Mr. McCulloch points out that this design eliminates cross-talk signal transmission problems that can occur with radio-frequency probe systems as well as signal interference that can occur with optical systems when using large fixtures or when debris collects on optical signal receivers.

Related Content

How to Choose the Correct Fixed-Body Plug Gaging Solution

The two types of fixed-body plug gages are both accurate, fast and easy to use. Consider these factors when selecting one for your gaging application.

Read MoreRethink Quality Control to Increase Productivity, Decrease Scrap

Verifying parts is essential to documenting quality, and there are a few best practices that can make the quality control process more efficient.

Read MoreProcess Control — Leveraging Machine Shop Connectivity in Real Time

Renishaw Central, the company’s new end-to-end process control software, offers a new methodology for producing families of parts through actionable data.

Read MoreHow to Calibrate Gages and Certify Calibration Programs

Tips for establishing and maintaining a regular gage calibration program.

Read MoreRead Next

5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More