A Brainstorming Technique to Increase Manufacturing Employee Engagement

This technique works for just about any type of question for which independent and unbiased answers are sought.

Share

Through the years, I have employed various brainstorming techniques for the purpose of obtaining employee input on key issues facing different organizations. There are certainly many techniques to choose from, and some have worked quite well, while others have left me unsure of whether I really got the information I was seeking.

Recently, I learned of a technique that engages participants and prevents domination of the conversation by a few, which always tends to sway the ideas of others. I have employed this structured brainstorming technique in a number of instances with some pretty impressive results. I am not sure if the technique goes by a specific name, but I liken it to speed dating. The technique works as follows:

- Break participants into small groups. Six or eight people per group seems to work well, with an even number making the process much more manageable and ensuring full engagement of participants.

- Set up chairs in two equal lines facing each other, with one chair per participant.

- Give everyone in the group one question for which they are responsible to ask. Have them collect answers, as well. If there are multiple groups, give each group the same questions (unless you want to get answers to a lot of different questions in one session).

- To start, teams of two participants sit face-to-face, and the first participant asks the participant facing him or her the assigned question and records the answer.

- Next, the second participant does the same with his or her question.

- A total of four minutes is allowed for the two participants to ask their questions (approximately two minutes per question). This keeps the process moving and prevents unwanted conversation. Interestingly, most teams finish well within the four minute time limit, even though this time seems very short at first.

- At the end of the four minutes, the teams are notified (a bell or whistle works well), and all discussion stops.

- Each participant then sits with a different participant, forming a new team of two sitting face-to-face.

- The process repeats until each participant has met with every other participant in the group and has asked each question. There will always be one less round of discussion than the total number of participants. For example, six participants will ask and be asked questions five different times during the brainstorming session.

- Each participant records the answers he or she has collected on a chart or other display that is visible to everyone in the group.

- Group discussion then occurs, but the most frequent answers to the questions are typically given highest priority for further action.

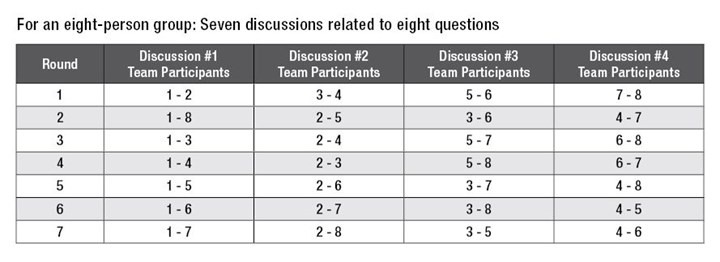

When following this brainstorming technique, it is best not to have the participants select their discussion partners for each round as this can get a little complicated. Instead, a chart like the one below should be developed ahead of time, to minimize delay.

Such a chart can be modified to reflect the number of participants and rounds of discussion needed to answer all of the questions.

This structured brainstorming technique works for just about any type of question for which independent and unbiased answers are sought. Questions involving safety, product quality, process issues, continuous improvement, new equipment, customer service, key performance indicators (KPIs), cost reduction and even new product development are especially well-suited to such an approach.

Try this technique the next time you want to solicit input from your team. I think you will find it to be an effective way of increasing the engagement of your employees, which could generate a wealth of new ideas for your organization to consider.

Related Content

Same Headcount, Double the Sales: Successful Job Shop Automation

Doubling sales requires more than just robots. Pro Products’ staff works in tandem with robots, performing inspection and other value-added activities.

Read MoreThe Power of Practical Demonstrations and Projects

Practical work has served Bridgerland Technical College both in preparing its current students for manufacturing jobs and in appealing to new generations of potential machinists.

Read MoreDN Solutions Responds to Labor Shortages, Reshoring, the Automotive Industry and More

At its first in-person DIMF since 2019, DN Solutions showcased a range of new technologies, from automation to machine tools to software. President WJ Kim explains how these products are responses to changes within the company and the manufacturing industry as a whole.

Read MoreBuilding Machines and Apprenticeships In-House: 5-Axis Live

Universal machines were the main draw of Grob’s 5-Axis Live — though the company’s apprenticeship and support proved equally impressive.

Read MoreRead Next

Use the SMART Criteria to Develop Your Company's Goals

Be SMART, and use these five characteristics to improve your company.

Read More5 Rules of Thumb for Buying CNC Machine Tools

Use these tips to carefully plan your machine tool purchases and to avoid regretting your decision later.

Read MoreRegistration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read More

.jpg;maxWidth=300;quality=90)