Workforce Development

Job Shop-Developed Dovetail Fixture Takes Wing

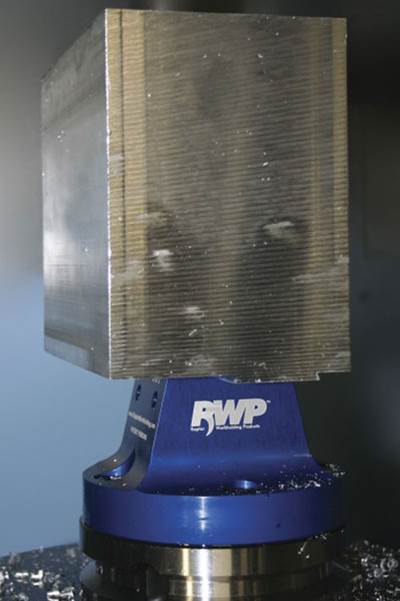

Two aerospace job shops in California collaborated to produce a workholding fixture that allows any shop to set up a fully fixtured pallet dedicated to a five-axis job and then store the fixtured pallets for immediate use whenever the job repeats.

Read MoreSurfware Opens Demo, Training Center

Surfware, developer of SurfCAM Velocity CAD/CAM systems, has opened a new demo and training center in Camarillo, California. The facility will serve many functions, including a role as a multimedia center where live demonstrations of the company’s TrueMill and SurfCAM software will be filmed and made available via the Surfware Web site, YouTube and other communication outlets. Live Webcasts broadcast from the center will allow viewers worldwide to see demonstrations of TrueMill in high speed titanium cutting applications on a Haas machine.

Read MoreCNC Training Software Available On CD ROM

Siemens Energy & Automation offers its SinuTrain solution, a package of CNC training software on CD-ROM that runs with Windows XP. To further speed the program-generation protocol, NC programs can be developed and simulated using a direct connection to the company’s CAD systems. In this way, mill and lathe operators not only learn the control language commands, but also visualize part programs on PC screens that are identical to actual machine screens.

Read MoreGetting Credit Where Credit Is Due

Although current economic climate is by no means conducive to securing a lease or loan for a new machine or other equipment, shops with the right plan in place can still obtain the financing they need. One expert offers some advice for manufacturers seeking to obtain equipment financing amid the downturn.

Read MoreYearly Conference Offers Hands-On CAD/CAM Training

DP Technology (Camarillo, California) announces the next edition of the Esprit World Conference. Scheduled for May 12 through 15 in San Diego, California, the annual event offers a suite of product training courses, business presentations and networking opportunities for the company’s Esprit CAD/CAM software user community. The conference will mark the public introduction of the latest versions of the software, including Esprit 2010, Esprit Mold v11 and Esprit SMINNC v2.

Read MoreTurnkey Service for Precision Part Production

The company provides a turnkey service that facilitates production of precision parts suitable to run on cam-type Swiss automatics. Personnel work in-house to cover requirements for the entire process, from initial cycle time estimates to the final machine acceptance run. Customers have reported ROI of 6 months because of the low package price, the company says.

Read MorePrecision Manufacturing Skills Standards

NIMS is an American National Standards Institute (ANSI)-accredited developer of precision manufacturing skills standards and competency assessments. Credentials for CNC milling operators and CNC turning operators are the most recent certification products available from National Institute for Metalworking Skills (NIMS). Also, the first on the job trainer and training coordinator (OJT) certifications were issued at the beginning of last year.

Read MoreInstitute Offers Machine Training, Counseling

Recently opened on a 146-acre campus adjacent to Florence-Darlington Technical College in Florence, South Carolina, the Southeastern Institute of Manufacturing and Technology (SiMT) provides local industry with advanced machine tool training. SiMT offers engineering, CAD/CAM, rapid prototyping and 3D virtual reality services as well as workforce development and business process training. Housed within the facility is the Advanced Manufacturing Center (AMC), which provides machine tool systems training for the southeastern United States.

Read MoreKitagawa Continues Educational Outreach Efforts

While the lack of young people coming into manufacturing industries has been a concern for years, the situation has yet to improve, says Bill Graham, marketing manager for Kitagawa-NorthTech. Mr. Graham believes the industry as a whole needs to better support teachers who are interested in teaching technical skills and dispelling myths about manufacturing.

Read MoreSandvik Contributes To University Lab Development

Sandvik Coromant recently collaborated with Purdue University’s School of Engineering Education to supply tooling solutions and services for the school’s Ideas to Innovation (I2I) Learning Laboratory. The lab, which doubles as a Haas Technical Education Center, will provide nearly 1,700 first-year engineering students with hands-on design experience. The collaboration between Sandvik and Purdue was established in mid 2008.

Read More