Workforce Development

Open Your Own Machine Shop? Here is Advice On Starting Small

Read what shop owners had to say to someone who wondered whether he should open a very small shop of his own.

Read MoreStudents Improve Math, Science Skills

Math skills often critical for success in manufacturing are on the rise among young people, according to the recently released Trends in International Mathematics and Science (TIMSS) report. TIMMS is an international comparison that measures the mathematics and science knowledge and skills of fourth and eighth graders. The report indicated that fourth-grade students in the United States improved 11 points in math between 2003 and 2007, while eighth graders have jumped 16 points since 1995.

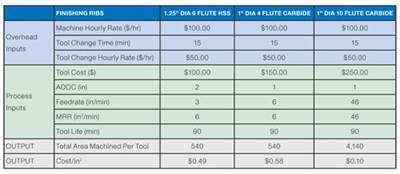

Read MoreHow To Machine Aircraft Titanium: Pricing The Process Instead Of The Tool

Part of a series of articles on more efficient machining of pockets in titanium parts, this article describes the importance of considering all of the costs that are affected by the choice of cutting tool.

Read MoreSchool Recognized for Manufacturing Program

Max Hayes High School in Cleveland, Ohio was recognized by the National Institute for Metalworking Skills (NIMS) as the first urban high school in the country to achieve NIMS educational training program accreditation. The purpose of NIMS accreditation is to improve the quality of training programs as part of a national endeavor to build and maintain a globally competitive workforce while providing workforce development opportunities for potential and current employees. In addition to credentialing requirements, earning accreditation requires three steps: registering the program with NIMS, completing a self-study analysis and conducting an on-site audit.

Read MoreBlack Oxide Process Reduces Time And Labor Costs

Birchwood Casey’s automated Tru-Temp finishing system uses a two-stage oxidation process to form a black magnetite finish on all iron and non-stainless steel parts. The process is said to operate effectively at a temperature 100oF lower than other black oxide processes that require a temperature of 290oF. The result is a protective black finish that is 0.

Read MoreSandvik Opens New Training, Demo Facility

Sandvik Coromant (Fair Lawn, New Jersey) recently hosted a ribbon cutting ceremony and open house to commemorate the opening of its new Chicago Productivity Center in Shaumburg, Illinois. The facility contains classrooms, meeting areas, a tooling showroom and a dedicated machining floor. The fourth of its kind in North America, the new center joins existing locations in Fair lawn, New Jersey; Mississauga, Ontario; and Monterey, Mexico.

Read MoreShoptech Partners With Vincennes University

Shoptech Software has partnered with Vincennes University through its Computer Integrated Manufacturing Program. The software developer has donated its E2 Shop System to help students learn the skill sets needed to succeed in a computer integrated manufacturing environment. “E2 will be the exclusive shop management system in our curriculum,” says Doublas Brown, dean of MTDAM at Vincennes University.

Read MoreCNC Training Software Uses Actual NC Programs

Siemens Energy & Automation’s SinuTrain CNC training software is designed to run with Windows XP and is said to be suited for machine tool control-identical simulation training. The software is designed to provide mill and lathe operators with a high degree of practical hands-on experience prior to using the CNCs for the first time, the company says. While using the application, NC programs are developed and simulated using a direct connection to the company’s CAD systems to further speed the program generation protocol.

Read MoreContest Winners Display Creativity, Skill

Mori Seiki USA has announced the winners of the 2008 Innovation of the Americas machining competition, which is designed to recognize talented machinists in the metalworking industry. Four professionals from reputable industry organizations and universities, led by Professor Kazuo Yamazaki of the University of California, Davis, judged more than 130 entries in four categories. The entries represented a wide range of materials, sizes and shapes, and were of such high quality that selecting winners was challenging for the judges.

Read MoreThe Connection Between Labor and Lean

Lean manufacturing is about identifying and optimizing variables that affect cost and time. This same systemization can make the process easier to staff.

Read More