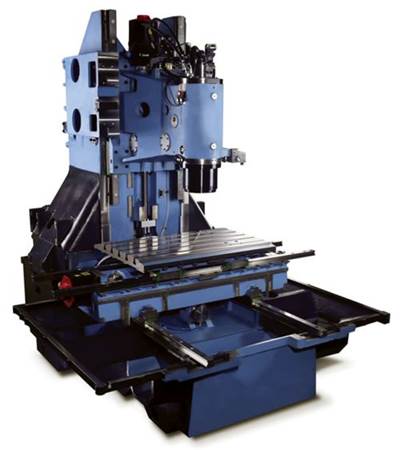

Vertical Machining Centers

Pallet Changer Keeps Machine and Operator Busy

A new VMC with an automated pallet changer helped this shop meet customer requirements for lower prices and faster deliveries.

Read MoreSidehead Offers Optimum Angle for Turning Tall, Flanged Parts

A sidehead option is available for Mag vertical turning centers (VTCs) equipped with tables ranging from 1,250 to 3.500 mm (49.2" to 137.7" that can accommodate 3,300-mm (129.9") tall parts with diameters ranging to 3,700 mm (145.6").

Read MoreVMCs Increase Productivity, Quality

Makino’s PS-series VMCs for production machining are designed to reduce cycle time, increase productivity, improve quality and minimize capital investment.

Read MoreShop Finds Perfect Fit in New VMC

A Feeler VMC from Methods Machine Tools helped this shop produce larger parts more efficiently and accurately.

Read MoreHow Micromachining Patience Speeds Prototype Production

A molder of tiny, silicone components for the medical industry explains how a patient, conservative approach to micromachining enables it to deliver prototypes faster.

Read MoreWhat Makes for an Effective, Production-Oriented VMC?

Extended VMC cycle times due to modest spindle performance and slow non-cutting functions can increase costs for high-volume applications. However, new VMC offerings can minimize cycle times while maximizing competitiveness for production work.

Read MorePrecision Micromachining Center for High Speed Machining

Makino says its iQ300 precision micromachining center incorporates the latest advances in machine and spindle design, thermal control and precision.

Read MoreOtherworldly Precision

A contract shop produces critical parts for the Curiosity rover that will soon depart for Mars.

Read MoreTransforming Industrial Robots into Precision Machine Tools

Robots fitted with an adaptive control system get real-time course corrections throughout the machining cycle.

Read More

.jpg;maxWidth=300;quality=90)