CAM Software As A Creativity Tool

This job shop relies on its CNC programming software to unlock the productivity of its multi-axis, multi-tasking machine tools and CNC Swiss-type machines.

Share

The formula for this job shop’s success is simple: Be better than the competition at making complex precision parts on complex, high-tech machine tools.

The shop is Evans Machining Service in Clairton, Pennsylvania, about 12 miles south of downtown Pittsburgh. The shop is owned and managed by the Evans family—a father and his three sons. Mother also helps out with shipping and paperwork, and a sister works part time. Three other skilled machine operators round out the shop production crew.

To be a winner, the shop must have multi-tasking machines with subspindles and sliding headstock lathes with Y-axis milling, but that is not enough. “You also have to be more creative in how you process parts on these machines than everybody else,” says Dan Evans, the no. 3 son who does most of the off-line programming for the shop’s Mazak Integrex machines, Marubeni Citizen-Cincom CNC Swiss-type machines and assorted CNC vertical machining centers.

Creative use of advanced machining technology sets this shop apart. It is very good at using these machines to complete complex parts in one setup. This efficiency enables the shop to win substantial contracts to make critical parts as a prime contractor to the U.S. Department of Defense (DoD).

What “creative use of technology” means in practical terms, however, is that Mr. Evans is an exceptionally talented programmer. He has a gift for visualizing how a part can be manufactured using the full capability of these complex machines. He knows how to make the most of all their tooling possibilities, simultaneous operations and multi-tasking features.

But Mr. Evans doesn’t pull these programs out of thin air. He studies the part geometry carefully and begins to think about the 3D shape of the blank part. He pictures in his mind how various turning and milling operations can generate the finished geometry from the raw stock.

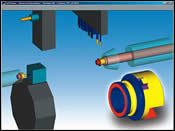

This is where the special features of his programming software make a difference. The software, PartMaker CAD/CAM by PartMaker Inc. (Fort Washington, Pennsylvania), allows Mr. Evans to “noodle” on the computer screen as he puts his ideas about part processing into discrete machining operations in the CNC program.

“I have to let my mind reach out of the box to test and experiment with different approaches to making the part,” Mr. Evans explains. He says the software lets him quickly describe the machining steps he sees in his mind. Then the program simulation feature shows him how each step changes the shape of the workpiece. He can see, for example, how the sliding headstock or the turret with live tooling will react to the programming commands. The instant graphical confirmation tells him right away whether his thinking is feasible. Often, when he sees the simulation, a better way to make the part pops into his head. “The software lets me quickly move machining steps around and then see how that change improves the way the part is taking shape,” he says.

The software also helps him synchronize machining steps to take advantage of the potential for simultaneous operations, especially on the Swiss machines. This is important, because having two or more operations taking place at once can reduce cycle times by half or more. “Often I see how moving a step from the front-end operations to back-end working on the subspindle after cutoff will give me an advantage. The software lets me try this and see how it works,” Mr. Evans says.

With this programming capability as a creativity tool, the shop has unlocked the potential of its multitasking machines as productivity tools. The combination of these creativity and productivity tools underlies its formula for success. With these tools, the collective skill, imagination and hard work of everyone in the shop can be directed to the goal of reliable precision parts manufacturing.

Aiming High

Most of these precision parts are spares for small-caliber machine guns used by several branches of the military. This is the shop’s specialty. The company also produces parts for tracked vehicles and weapons systems used on jet fighters. Allen Evans, Sr. started the shop in 1982 after 23 years as a journeyman machinist with a large company that served Pittsburgh’s steel industry. Consolidation in the industry forced this company to close, leaving Mr. Evans with one viable option—opening his own business as a machining job shop. Although he started out with manual mills and lathes, Mr. Evans knew that CNC represented the best chance to grow and thrive. His youngest son, Dan, was just a teenager when the shop acquired its first CNC lathe. Together, the father-and-son team learned how to program and operate the machine.

Dad had the machining skills; his son had the aptitude for working with computers. As the shop grew, the other sons joined the company. Allan is an applications engineer, and Tom oversees production as an operations manager.

One of the most important lessons learned as a start-up shop was to have no fear of emerging technology. The shop could keep its competitive edge only by embracing new developments and accepting the strenuous challenges that accompany them. The senior Mr. Evans watched other shops in the area resist this approach and fall by the wayside as a result.

Moving into military contracts in the early 2000s when commercial work was drying up put this brave outlook back to the test. “We knew that meeting government specs for quality inspection, paperwork, surface treatments and packaging would take more discipline and organization, but we accepted it as a part of the job,” Mr. Evans recalls. At first, negotiating contracts and dealing with government purchasing agents was complex and frustrating. Yet it became clear that going after jobs for difficult-to-machine parts represented a strategic opportunity—if the shop could master the multi-tasking, multi-axis machines required to handle this work efficiently. Shops that were intimidated by this technology or unable to use it effectively would be out of the running, leaving a narrow field of competition for Evans Machining to bid against.

The shop bought its first Integrex multi-tasking machine from Mazak (Florence, Kentucky) in 2002, followed by a second, larger Integrex model in 2004. It also invested in two Citizen-Cincom Swiss machines from Marubeni (Allendale, New Jersey) during this time. These CNC machines replaced several cam-driven Swiss-type automatics that had served the shop for years.

Picture This

As chief programmer, Dan Evans quickly realized that programming these machines effectively would be critical. Unfortunately, the programming software he was using was inadequate. It got in the way of how he had to think about part processing on these machines.

He wanted an interactive, more intuitive programming system that could help him discover and develop effective part programs. As he saw it, you can’t solve the problem of how to machine complex parts on turn-mills or subspindle lathes by thinking only in a straight line. That’s not how the mind of a creative and intelligent programmer works. Trouble is that most software for this kind of machine requires a sequential, step-by-step list of operations. That might be a good way to capture a process plan, but it doesn’t always help the programmer do the original thinking about how to make the part.

Mr. Evans saw PartMaker software at another shop with machines similar to those in his shop. He saw immediately that this software could do the job his way. It seemed to lend itself to the kind of creative thinking that a programmer needs to follow when confronted with complex parts. The structure of this software allows the user to manipulate machining steps interactively with the simulation. With this approach, the programmer can see how the part shape could change as machining operations occur. This gives the programmer natural insight into how the part can be made using the full capability of the machine.

For example, the software should enable this kind of thinking: “I can’t do that step at this point, or the part will fall out of the guide bushing. I’ll have to wait until cutoff and transfer the subspindle, and then finish that step with the back working tools.”

As Mr. Evans explains, “The machines are designed to have more than one operation going on at once. To get this simultaneous machining to work effectively, you have to have the various steps in the right order—but that order is not strictly sequential. You have to have all the machining steps outlined in your mind so that the right order for arranging them in time becomes apparent.”

According to Mr. Evans, the software facilitates this by creating a process table, which is simply an array of all the steps that need to be executed to make the part. By shuffling steps into a different order, the programmer can build a program that fits the capability of the machine and follows an intelligent strategy.

The ability to come up with this strategy sets one shop apart from another. “Any shop can own a turnmill or a Swiss automatic. The difference is going to be which shop does the best job of programming these machines, and that depends on how well a creative and experienced programmer can envision a smart way to machine the part,” Mr. Evans says.

Not As Simple As It Looks

The part shown on page 85 is a representative example. It’s a keyed gas cylinder insert for a machine gun. The key is a match-head-sized square protrusion on the OD of the part, a feature that makes this otherwise simple-looking component difficult to machine. Tolerances are tight, because the smooth and reliable operation of the weapon in combat depends on the quality of this critical part. It calls for careful programming.

The part is machined from 1.25-inch diameter round bar stock on the Cincom M32 lathe, which has a Y-axis turret. Turning operations in the main spindle create a flange that can be milled away to leave the keyed tab. Mr. Evans builds the process table step-by-step by opening graphical windows that represent various machining operations on the different planar or rotational faces of the part, such as the front face, back face or side face. Entering values and making menu selections allows him to quickly parameterize each operation.

The results appear as a descriptive line in the process table. Mr. Evans can switch from milling to turning operations by opening the appropriate window. By running a simulation of each step as it is added, he can visualize the part as it will be machined. He can rotate, zoom or pan the simulation in stop-action mode to study the results. Different colors in the simulation represent the various machining operations, thus making the results of each operation very apparent.

By pointing and clicking the mouse on lines of the process table, Mr. Evans can shuffle the order of operations and rerun the simulation. Because lines in the process table are descriptive, identifying the step that he wishes to move or modify is easy.

For example, when viewing the simulations, Mr. Evans considers how the direction of the cutting tool might push a burr to one side or the other and how this burr might affect subsequent operations. He will change the order of machining operations to keep a possible burr from interfering with the motion of the headstock. In other cases, he will be sure any burr is pushed to an edge where subsequent operations will remove it while machining another part feature. Mr. Evans says that the interactive nature of the software makes anticipating and managing this sort of machining effect easy.

Although the programmer can choose the most logical order of various milling and turning operations on different faces of the part, the software keeps operations for front-, back- or side-working faces in separate processes. These processes can then be synchronized for simultaneous operations. Possible collisions or clearance issues are identified in simulation and must be resolved by the programmer before proceeding.

Machining From The Solid

Although the shop often starts with precision castings as blank workpieces, multitasking machines have definitely made machining from the solid a preference. For example, any part that will fit inside the diameter of bar stock that the Swiss machines will accommodate is considered a candidate for machining from the solid. This means that the shop is accustomed to processing irregular, prismatic parts on these machines. This option would be far less attractive if programming difficulty were an obstacle.

Some of advantages of this approach as Mr. Evans enumerates them include:

- No leadtime associated with the preparation of tooling for the casting process.

- Cost of tooling can be eliminated.

- The barfeeder on the Swiss machines acts as built-in automation for lightly attended operation.

- The sliding headstock keeps machining operations close to the spindle bushing where minimal overhang enhances rigidity.

- The value added by completely machining parts in one setup justifies the investment in this technology, whereas minimizing machine time by using a precision casting puts an economic burden on machining operations that the necessary equipment might not be able to support. (“There’s no money in machining simple features,” as Mr. Evans’ father puts it.)

Mr. Evans also prefers machining parts from the solid, because the challenge appeals to his sense of the artistry and creativity in the programming process. In essence, the process of turning his vision into reality is a gratifying experience.

The Next Generation?

The Evans family is confident that it can continue following its formula for success. The elder Mr. Evans worries more about the industry as a whole. He doesn’t see another generation being readied to assume the responsibility—and opportunity—to support the manufacturing requirements of the country’s military establishment. Being part of a successful job shop is demanding work that calls for intelligent, imaginative people who can tolerate an often high-pressured environment, he says.

He is concerned that those with this level of talent seem bound to look elsewhere for careers. “The work we do here is important, and it gives us a chance to use our skills as craftsmen. It’s too bad the rewards to being a part of this are not as well understood as they used to be,” he notes.

Nevertheless, Mr. Evans believes in what his shop can do with its combination of creativity and productivity tools. The company plans to add another subspindle lathe in the short term and is looking at installing its own heat-treating line in the long term. These are signs of growth and optimism, too.

Related Content

6 Machine Shop Essentials to Stay Competitive

If you want to streamline production and be competitive in the industry, you will need far more than a standard three-axis CNC mill or two-axis CNC lathe and a few measuring tools.

Read MoreHow to Determine the Currently Active Work Offset Number

Determining the currently active work offset number is practical when the program zero point is changing between workpieces in a production run.

Read MoreHow to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

Read MoreBallbar Testing Benefits Low-Volume Manufacturing

Thanks to ballbar testing with a Renishaw QC20-W, the Autodesk Technology Centers now have more confidence in their machine tools.

Read MoreRead Next

Making It In Medical Machining

Examining this shop's healthy medical machining business shows that both medical components and medical customers require special care.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More