Turning Tools

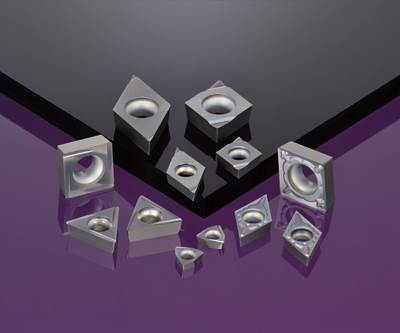

Coating on Turning-Grade Inserts Resists Adhesion, Microchipping

Westec 2017: Sumitomo will showcase its line of AC1030U turning grade inserts for precision machining, which are available in many geometries, including the company’s GND grooving line.

Read MoreChip Breakers Suited for Both Rough Machining, Fine Finishing

EMO 2017: Lach Diamant will demonstrate its PCD IC-Plus chip breakers, which the company says perform well during both rough machining and fine finishing when using long chipping aluminum alloys.

Read MoreBimodal Substrate, Coating Extend Tool Life of PCBN Insert Grades

Seco Tools has expanded its family of PCBN insert grades for hard part turning.

Read MoreInserts, Holder for Swiss-Style Applications Lengthen Tool Life, Increase Productivity

Carmex Precision Tools has released Swiss-Line, the latest addition to its family of tooling for Swiss-style applications.

Read MoreTurning Insert Offers Greater Resistance, Edge-Line Security

Sandvik Coromant has introduced the GC2220 dedicated turning insert optimized for stainless steel materials that offers increased productivity, longer tool life and higher machine utilization

Read MoreSmaller Economical Turning Inserts, Holders Maintain Same Performance

Tungaloy is expanding its economical ISO-EcoTurn turning insert and holder system to include VNMG inserts and holders.

Read MoreInsert Grade Excels in Turning Uneven Forged Surfaces

Sandvik Coromant has introduced its GC4335 insert grade for the turning of steels where unstable conditions or vibration issues prevail.

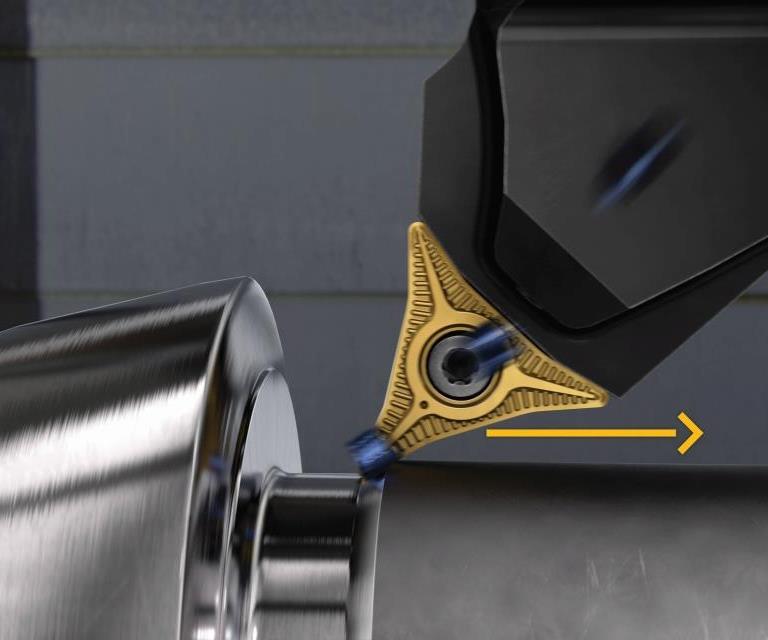

Read MoreNew Turning Process Can Drastically Cut Cycle Times

Sandvik Coromant’s PrimeTurning process allows turning and facing in all directions, delivering dramatic increases in high-volume production. Cycle time reductions of 50 percent or more can be achieved.

Read MoreA New Turning Process Enables Cutting “In Reverse”

A methodology for cutting in both directions on a CNC lathe promises to make turning a much more productive operation in certain applications. New types of inserts driven by new CAM tool paths are key enablers of this development, but implementing the whole multifaceted system as a system is essential.

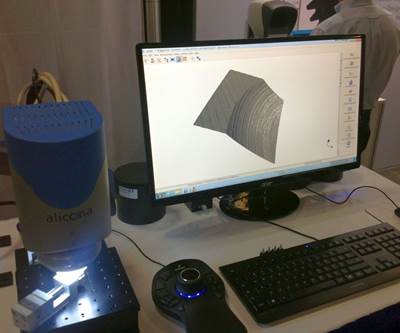

Read MoreHot Temperatures (and Technologies) at Eastec 2017

Eastec’s peculiar Massachusetts venue offered the chance to sample a broad variety of advanced manufacturing technologies. Here is a slideshow and some impressions from the trade show.

Read More