Tooling

Machine Tools Used As Dedicated Equipment…For A Little While

Two keys to this shop’s success are versatility and speed. It uses flexible machining centers, rather than dedicated equipment, and constantly reconfigures them into new cells for new jobs. The speed at which it can do this, in addition to in-house tombstone manufacturing capability, provides the nimbleness to quickly respond to its customers’ needs.

Read MoreHigh Speed Machining Without The Fast Spindle

Relying on axial chip thinning lets a larger-diameter tool realize some of the benefits of high speed machining even if the machine's spindle speed is low.

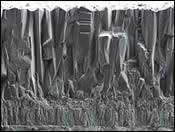

Read MoreAtomic-Level Engineering For Greater Tool Life

Manipulating the direction of aluminum oxide crystals produces a cutting tool coating that is harder, and also cuts cooler.

Read MoreHow CNC Led To Cells

Bringing CNC into a previously manual process set this shop on a lean path that has led to continuous flow production.

Read MoreDouble-Sided Productivity

Having a bar feeder on one side and a parts carrousel on the other side ensures that a turn-mill machine will achieve maximum productivity, whether the workpieces are mostly milled or mostly turned. In general, smaller parts are machined from bar stock, even if only milling operations are involved. Larger parts are loaded an unloaded by a transfer device fed by the carrousel.

Read More

.jpg;maxWidth=300;quality=90)