Tooling

Walter Introduces Coated Grade for Machining Aluminum

The WXN15 coated grade inserts can be used for copy milling, face milling, ramping, pocket milling and circular interpolation milling.

Read MoreSandvik Coromant Extends Line of Ceramic Milling Heads

Sandvik Coromant has developed two solutions designed for shoulder and face milling of nickel-alloy aero-engine parts.

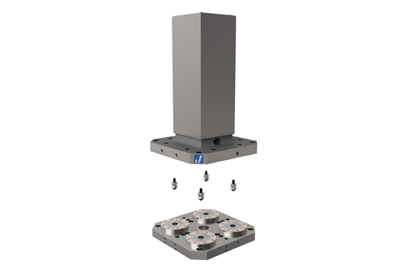

Read MoreJergens Inc. Introduces Cast Iron Tooling Columns

The cast iron tooling columns are said to increase horizontal machining potential and provide a solid basis for custom workholding to suit specific customer needs.

Read MoreSimple Workholding for Robotic Automation

Robotic automation relies on reliable workholding, and these modular pneumatic jaws make it simple.

Read MoreHeidenhain Introduces In-Process Gage to Check Tools

The TD 110 tool breakage detector can determine whether a tool is broken off by more than 2 mm as it passes within a machine tool.

Read MoreSandvik Cormant Introduces Lightweight Milling Tool

The new CoroMill MF80 for automotive milling offer a 40% lighter cutter body with shim protection and a high number of inserts.

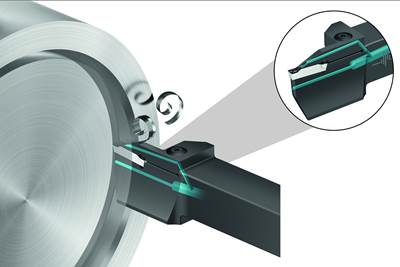

Read MoreWalter Launches Axial Grooving System With Precision Cooling

The G1111-P/GX24 AF5 axial grooving system reportedly delivers maximum productivity and cutting parameters due to optimal cooling, strength and controlled chip breaking.

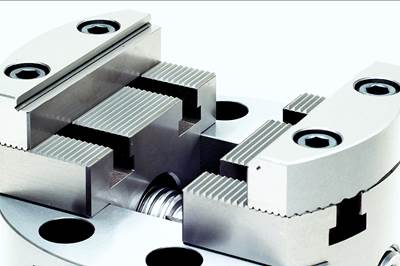

Read MorePalmgren Vises Enable Five-Sided Access to Workpieces

Palmgren’s Five-Axis Machine Vises are equipped with self-centering jaws that reduce clamping time and provide a workholding solution for a variety of workpieces, including square, round or odd-shaped parts.

Read MoreMoving To Magnets Doubles Productivity

Moving from hydraulic to magnetic fixtures enabled this shop to reduce setup time, improve rigidity and eliminate manual operations. As a result, productivity doubled.

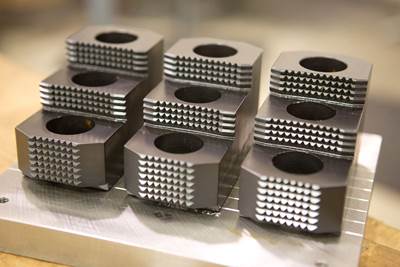

WatchDillon Manufacturing Provides Top Jaws With Custom Dimensions

Dillon’s custom, special or modified hard-, soft- or full-grip top jaws are said to be compatible with virtually any chuck manufacturer.

Read More

.jpg;maxWidth=300;quality=90)