Jergens Inc. Introduces Cast Iron Tooling Columns

The cast iron tooling columns are said to increase horizontal machining potential and provide a solid basis for custom workholding to suit specific customer needs.

Share

Hwacheon Machinery America, Inc.

Featured Content

View More

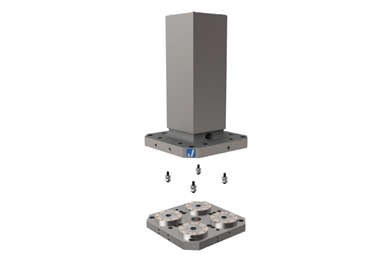

Jergens Inc. introduces its newest cast iron tooling columns that are said to offer maximum rigidity. These columns comprise one single piece of cast iron that is made in the U.S.A. They increase horizontal machining potential and provide a solid basis for custom workholding to suit specific customer needs.

Several mounting options are possible, including direct, with center pin locating or edge locating, and also quick-change applications via zero-point system (ZPS) with K20 pull studs and a four module subplate. New column styles include square, cross and rectangular. The square and cross styles are well suited for high density multi-part fixtures or incorporating multiple operations into a single column. The cross style enables the added benefit of increased spindle access near the column, eliminating the need for extra-long tools. The larger upright faces of the rectangular columns are ideal for applications involving larger workpieces.

Column construction uses stress relieved, class 40 cast iron, with the base and sides milled flat, perpendicular and parallel within 0.001" per ft., providing an accurate foundation on which to setup workholding devices or quick-change systems. Other features include a center locating bore, inch and metric hole patterns, M12 lifting holes for secure hoist ring attachment.

With technical staff support, Jergens tooling columns are customizable as well as easily integrated into full custom design and build projects. Popular patterns and methods include tapped grid, bushed and tapped grid for modular fixturing applications. For quick changes, add either Ball Lock receiver bushings or ZPS modules.

Related Content

-

Custom Workholding Principles to Live By

Workholding solutions can take on infinite forms and all would be correct to some degree. Follow these tips to help optimize custom workholding solutions.

-

Rail Manufacturer Moves Full Steam Ahead with Safe, Efficient Workholding Solution

All World Machinery Supply paired a hydraulic power unit with remote operating capabilities in a custom workholding system for Ahaus Tool & Engineering.

-

Custom Workholding Shaves Days From Medical Part Setup Times

Custom workholding enabled Resolve Surgical Technologies to place all sizes of one trauma part onto a single machine — and cut days from the setup times.

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)