Walter Introduces Coated Grade for Machining Aluminum

The WXN15 coated grade inserts can be used for copy milling, face milling, ramping, pocket milling and circular interpolation milling.

Share

Walter USA launches the WXN15 coated grade for machining ISO N materials. Walter says it is responding to the growing use of aluminum in the automotive and aerospace industries, as well as in general metalworking where it can increase machining speeds in a range of applications.

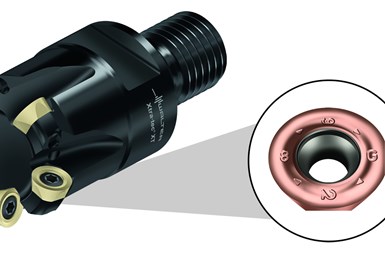

These WXN15 grade coated inserts are all introduced with a highly positive shaped geometry, which is effective in machining ISO N materials. When used in advanced cutter bodies like the new Xtra·tec XT M5468 button insert milling cutter, with G88 geometry, this also increases productivity when performing machining operations on deep shoulders with excellent chip removal.

These WXN15 grade inserts are available in 77 varieties of insert shapes, sizes and varying geometries to fit all of the most popular Walter milling families. WXN15 coated grade inserts can be used for copy milling, face milling, ramping, pocket milling and circular interpolation milling.

Though engineered for aluminum machining, most inserts of this WXN15 coated grade are said to be effective on other non-ferrous materials, as well as some steels, stainless steels, cast iron and even materials with difficult cutting properties, including hard machining.

Related Content

-

How to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

-

Sandvik Cormant's End Mills Eliminate Machining Chatter

The company’s CoroMill Dura line of solid end mills has been extended with aluminum-specific tools.

-

Walter Ceramic Inserts Enable Efficient Turning, Milling

Suitable turning and milling applications of the WIS30 ceramic grade include roughing, semi-finishing and finishing, as well as interrupted cuts.

.jpg;maxWidth=300;quality=90)