Tooling

Fixturing for the Automated Age

Koma Precision’s booth at IMTS 2022 features practical demonstrations of rotary tables, right angle heads and more.

Read MoreMiniature Inserts Reduce Tooling Change Frequency

Iscar’s Nanmill and Sumochan tooling lines simplify sharpening processes and reduce full tool change-outs.

Read MoreHaimer USA Models a Streamlined Toolroom

Haimer USA is celebrating its 20th anniversary with a live demonstration of its digital toolroom. Find out more past the aluminum panther.

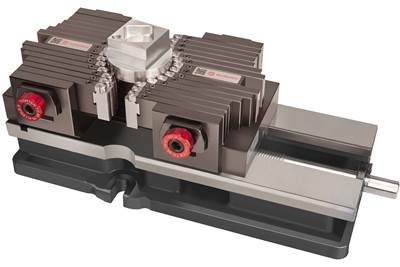

Read MoreNew Direction: An Interview with Kurt Manufacturing

IMTS 2022: Brent Donaldson, executive editor of Modern Machine Shop, sits down with Paul Carlsen of Kurt Manufacturing, to chat about the company’s redesigned booth and how it’s designed to solve customer problems.

Read MoreNew Division, New Product: An Interview with Norgren Workholding

Brent Donaldson of Modern Machine Shop chats with Corey Shidler of Norgren Workholding on the company's new soft jaw.

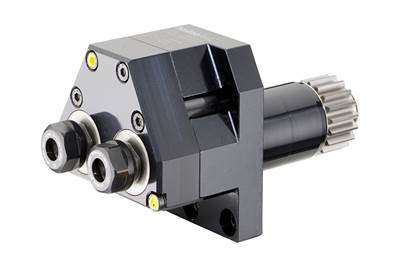

Read MoreSpeed Increasers Optimize Machine Parameters

IMTS 2022: Available for the most current Citizen models, the 1:4 speed increasers are said to optimize the machine’s parameters, making them both efficient and cost effective.

Read MoreWalter Introduces New Insert Grades for Turning Steel

Walter offers three Tiger·tec Gold grades specifically designed for turning operations in steel and cast iron.

Read MoreMini Indexable End Mills for Small Parts

The line features a V-Shaped pocket that cradles the insert to remove insert screw stress and foster effortless insert indexing.

Read MoreWhen Standard Tools Won't Do

GWS Tool Group offers a wide range of services to help customers acquire the tools to fit their needs.

Read MoreQuick Change Tooling Line Designed for Swiss-Type

IMTS22: Iscar releases the NEO Swiss Modular Quick Change Tooling Line to promote repeatability from job to job through strategic design.

Read More