Tooling

Drill Drives Tool Life, Cycle Time Improvements

This shop upgraded to through-spindle coolant as part of a lean manufacturing initiative but soon experienced tool life issues in drilling applications. With the Performax drill from Seco Tools, the shop not only addressed this problem, but also reduced costs and cycle time.

Read MoreDrill Helps Shop Balance Cycle Time, Part Quality

At Mill Equip Products, getting components out the door quickly is extremely important. A difficult drilling operation had the shop considering a $5,000 option for its milling machine to reduce cycle time until it found a simpler, less costly solution—the R458 MP-X drill from Dormer Precision. The drill’s geometry and long tool life enabled the shop to reduce production time on the job by more than two weeks.

Read MoreOne Tool, Two Turning Functions

A combination bar puller and cutoff tool is an inexpensive way to enable short stretches of unattended turning while saving a turret position.

Read MoreTilt/Rotary Table For 5-Axis Machining

CNC Indexing Technologies says its GSI CNCT-321 tilt/rotary table is designed for adding fourth- and fifth-axis productivity at minimal cost. The table allows users to machine as many as to five sides of a part while minimizing second and third operations and setups. The table has a 12.

Read MoreAxial Forces Control Workholding System

Emuge’s System SG expanding-bush design workholding system is used in hobbing, shaping and shaving operations for gear production as well as in milling and inspection applications. The system’s design is based on a series of short tapers that expand or contract when acted upon by an axial force. The system can be designed for ID or OD clamping, allowing for expansion and contraction.

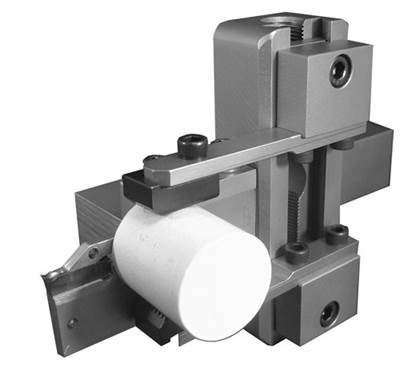

Read MoreStationary Clamping System

Schunk’s Tandem KSP plus stationary clamping system achieves a repeat accuracy of up to 0. 01 mm with the multi-tooth guidance of the base jaws, the long jaw guidance and the exact centering via the clamping sleeves which help reduce jaw lifting. The compact, clamping force block, which features a one-piece, rigid base body, achieves gripping forces ranging to 60kN.

Read More5-Axis Workholding System

Advanced Machine & Engineering announces the availability of the Triag 5axesClamp. According to the company, the spindle on a five-axis machine often has difficulty reaching all areas of a complex part using conventional workholding technology. The Triag workholding system minimizes interference, allowing machining spindles full access to workpieces, even in high-density applications.

Read MoreLow-Profile Rotary Table

The GD210LP low-profile rotary table from Hardinge is said to feature rigidity, speed, accuracy and repeatability. Large diameter bearings and a fail-safe clamping system provide high stiffness and high rigidity for parts weighing as much as 220 lbs. The table uses 233 foot-pounds (315 Nm) of clamping torque to handle off-center drilling, cross-axis milling and other high-force cutting applications.

Read MorePull Down Chuck

SMW Autoblok says its TX Pull-Down chuck features repeatability of up to 0. 0004″ (0. 01 mm) and is capable of operating under aggressive cutting conditions.

Read MoreMagnets Lift Flat, Round Materials

Eriez’s SafeHold XPL line of magnets can use one magnet to lift either flat or round materials. The magnets are available in six models with capacities ranging from 400 to 5,000 lbs for flat materials and 300 to 4,000 lbs for round materials. The small, lightweight magnets are constructed from Erium 3000 rare-earth, magnetic material, and they feature a powerful, magnetic force.

Read More

.jpg;maxWidth=300;quality=90)