Drill Drives Tool Life, Cycle Time Improvements

This shop upgraded to through-spindle coolant as part of a lean manufacturing initiative but soon experienced tool life issues in drilling applications. With the Performax drill from Seco Tools, the shop not only addressed this problem, but also reduced costs and cycle time.

Share

When a shop runs at full capacity, it must make efficiency gains any way possible. A few years ago, one such shop, Kennebec Tool & Die, embarked on a lean manufacturing program to eliminate waste and improve productivity. With 70 employees working in three shifts around the clock seven days a week, the Augusta, Maine-based company needed to standardize processes, equipment and tools in order to streamline its operations. One of the changes the shop made in order to meet its goals was to invest in a machining center equipped with through-spindle coolant.

However, the shop faced a persistent problem in its attempts to use the new machine and corresponding tooling for an important job—producing 700 assemblies per year for the semi-conductor industry. The shop was still on a learning curve for the new machine and tools, and cycle time issues on a particularly problematic component of the seven-part assembly reduced productivity.

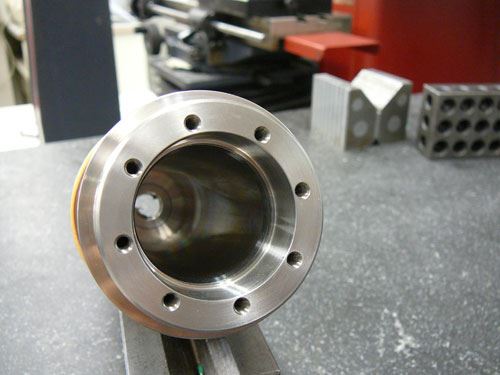

Made of 17-4 heat-treated stainless steel, the raw stock for the component arrives as a 4-inch-diameter bar that is cut to a rough length of 8.5 inches. After rough and finish turning, the component requires drilling of a 5-inch-deep internal bore with a tight tolerance. "Our turning operations were running pretty standard; it was really the drilling that was taking a long time," says Harvey Smith, vice president of operations.

Paul Owen, tooling room supervisor, says the source of the drilling operation’s lengthy cycle time could be traced to problems with consistent tool life. "Chips were wrapping around the drill, destroying the tool and/or scrapping the part," he explains. "We might get five parts from one insert and then six or eight from another."

Kennebec tried to work through the problem, but had to slow down the entire process in order to clean out the chips, further impacting productivity. The shop knew it needed to upgrade its drilling tools. However, in keeping with its lean manufacturing program, it sought to do so with the goal of not only addressing this specific application, but also reducing its total number of drill styles by finding a product that would work in a variety of situations. Soon, it had narrowed the vendors down to Seco Tools (Troy, Michigan) and a competitor.

To make a decision, Mr. Smith issued a challenge to Seco technical specialist Bryan Daniels: "If you can make this particular operation work, then I’m changing over to Seco."

Mr. Daniels delivered. He suggested a 1.187-inch-diameter, 5×D Perfomax indexable drill for the troublesome assembly component application. The Perfomax drill features two coolant holes and large chip flutes with a flute angle that is said to promote efficient coolant flow and effective removal of coolant and chips. This flute and the tool’s coated body and inserts are designed to allow high feeds and speeds while avoiding deflection, poor tool life and quality, even with long lengths and deep-hole drilling applications. Unlike many other indexable drills, the Perfomax can use two different insert grades. A tougher grade is located in the inboard position, while a more wear-resistant grade is mounted in the periphery pocket. Inserts are square to provide a strong 90-degree corner and the economy of four cutting edges.

"The operation was pretty much nailed as soon as we tried it," Mr. Owen says. "Bryan suggested the feeds and speeds, and we had no problems. He worked with us and optimized the parameters until we got a good average of parts per insert."

The drill ended up producing about 20 parts per edge—a threefold improvement in tool life compared with the shop’s previous drill. Additionally, the tool reduced cycle time from 1.21 to 0.53 seconds. While this might not seem significant, Mr. Smith explains that the actual cycle time savings are greater than the numbers show because the shop previously changed tools every five to eight parts. The drill’s longer tool life provided cost benefits, as well. While the Seco inserts cost more than competitive inserts, the increased tool life achieved with Perfomax actually reduced the comparative cost by $1.05 per produced part, Mr. Smith says.

Now, Kennebec uses Perfomax for almost all of its standard drilling applications. In fact, the drill has worked well enough to prompt the company to give Mr. Daniels a chance to prove Seco’s worth in other areas, including an 8,000-part aerospace order that requires a combination of turning and milling operations. "After (Mr. Daniels’) dedication on this last process and the success we achieved, we will certainly at least give Seco a try," Mr. Smith says.

Related Content

Allied Machine Drill System Provides Enhanced Chip Evacuation

Eastec 2023: The T-A Pro drill body incorporates straight flutes designed for optimized coolant flow and rigidity.

Read MoreTungaloy Drills, Milling Inserts Provide Enhanced Stability

Tungaloy has expanded its DrillForceMeister and TecMill lines with new drill bodies and milling inserts.

Read MoreHeule Tool Enables Spot Facing of Difficult-to-Reach Areas

The manually actuated bkac spot facing tool is well suited for large boring mills and other open-air machines.

Read MoreCustom PCD Tools Extend Shop’s Tool Life Upward of Ten Times

Adopting PCD tooling has extended FT Precision’s tool life from days to months — and the test drill is still going strong.

Read MoreRead Next

Registration Now Open for the Precision Machining Technology Show (PMTS) 2025

The precision machining industry’s premier event returns to Cleveland, OH, April 1-3.

Read MoreSetting Up the Building Blocks for a Digital Factory

Woodward Inc. spent over a year developing an API to connect machines to its digital factory. Caron Engineering’s MiConnect has cut most of this process while also granting the shop greater access to machine information.

Read MoreBuilding Out a Foundation for Student Machinists

Autodesk and Haas have teamed up to produce an introductory course for students that covers the basics of CAD, CAM and CNC while providing them with a portfolio part.

Read More