Tooling

Zero-Point Clamping System

Quick Point, the zero-point clamping system from Lang Technovation, is said to be simple, safe and precise. Features include a holding power of 13,227-lbs down force, repeatability of less than 0. 00019" and overall pallet height of 1.

Read MoreTool Management System Reduces Costs, Downtime

Ineffective tool management can drive up costs and reduce efficiency even at the most high-tech, successful shops. With WinWare’s CribMaster Accu-Cab inventory management system, this aerospace manufacturer reduced costs, downtime and stock-outs resulting from missing or misplaced tools. In fact, meeting its return on investment (ROI) goals took only a few months.

Read MoreJob Shop-Developed Dovetail Fixture Takes Wing

Two aerospace job shops in California collaborated to produce a workholding fixture that allows any shop to set up a fully fixtured pallet dedicated to a five-axis job and then store the fixtured pallets for immediate use whenever the job repeats.

Read MoreHigh-Pressure, Quick-Release Clamps

The company’s quick-release clamping systems allow stepless adjustment both horizontally and vertically. The Multi-Quick 150 and 160 clamps feature a compact design with more clamping height and clamping reach. The solid clamping bar can form an extension of the machine table and provide secure, high clamping pressure by direct force.

Read MoreInsert Drills Cut Varied Materials

KUB Pentron line of drills provides length-to-diameter ratios of 5 × D. The system is equipped with two square inserts that have four effective cutting edges each. The internal and external inserts have exactly the same shape.

Read MoreProgrammable Tool Verification And Breakage Control System

The Mida Laser 75P non-contact programmable tool setting system incorporates a protection system with air-tunnel effect, a powerful integrated microprocessor for best performance under coolant, an active drip rejection filter and enhanced noise reduction with double filtering technology. The programmable system can be adapted to the tool type under verification, to the same rotation speed used during machining and to the desired measuring cycle. The system is available with a “collimated” or “focused” laser beam.

Read MoreFeed System Automates Production

According to the manufacturer, the advanced feed system allows companies to increase productivity, decrease setup time, reduce operator error and virtually eliminate waste. The feed system can turn a semi-automatic machine into a fully automatic production machine. Operators can either manually enter dimensions into the controller or pull a cut list directly from the controller.

Read MoreFront-Mount Collet Chuck

The self-contained, pneumatic B80 power collet chuck does not require a lathe, grinder or rotary table to have a hydraulic system, rear actuator, restrictive draw-tube or air-feed tubes. Instead, the collet chuck is operated by an air cylinder integrated into the collet chuck body. The device is especially useful for common toolroom lathes or flat-bed lathes, which typically don’t have hydraulic systems or other means to accommodate power chucks.

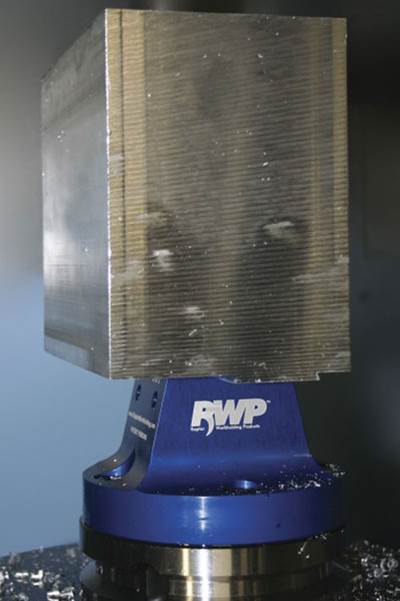

Read MoreHigh Clamping Force Toolholder

The powRgrip PG system uses a toolholder and collet to generate high clamping forces while maintaining a TIR of less than 0. 0001", the company says. The system is said to be ideal for high speed machining applications, and it can clamp tool shanks ranging to 1" in diameter.

Read MoreRapid Response Hydraulic Power Unit Program

The company says it can build, paint, test and ship custom hydraulic units in 3 days or less to anywhere in the world using its rapid response hydraulic power unit program. Both vertical- and horizontal-style units are available and range in size from 2 to 50 gallons. The 15-hp (maximum) units can deliver as much as 15 gpm at pressures ranging to 3,000 psi.

Read More

.jpg;maxWidth=300;quality=90)