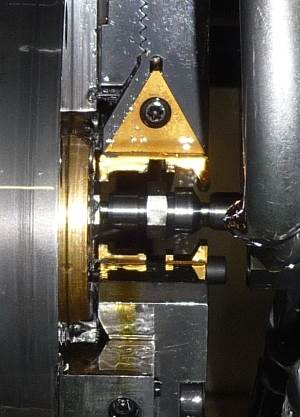

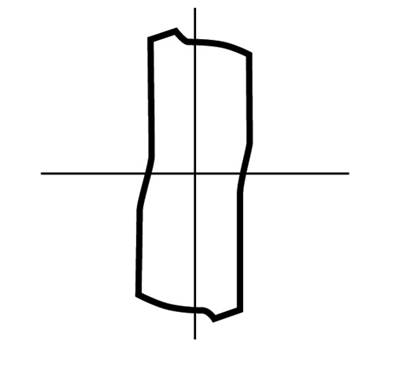

Tooling

Video: Form Tools On CNC Lathes

Form tools are traditionally associated with non-CNC machines, but in certain applications they make sense on modern machines as well.

WatchMoving Forward In Order To Stay Put

This job shop’s commitment to lean allows its business to grow while it remains in the facility where it has to stay.

Read MoreDeep Drilling Without Pecking Or Through-Tool Coolant

These drills enable machine tools to create holes with L:D ratios as high as 20:1 without pecking and without through-the-tool coolant delivery.

Read MoreBalanced Tool Assemblies Boost Quality, Efficiency

With balancing equipment and shrink-fit toolholders from Haimer USA, this manufacturer of automotive castings improved productivity, accuracy and surface finishes while extending tool and spindle life.

Read MoreZero-Point Clamping System(2)

According to manufacturer Hainbuch, the capteX zero-point clamping system cannot be harmed by the centrifugal forces in turning jobs or in the extreme static transverse forces associated with milling. Using a ring mechanism with sliding wedges, the interface can be stably fixed into place.

Read MoreQuick-Change Clamping System

Jergen’s zero-point clamping system is designed to reduce setup time while increasing accuracy and repeatability. Combining ease of alignment, high-accuracy positioning and high clamping forces with hydraulic or pneumatic actuation, the clamping system offers individual modules, complete systems and plates, design assistance and technical assistance.

Read MorePermanent Locator Capsules

Stevens’ locator capsules are permanently installed in holding fixtures for attachment and repeatable location on base surfaces. This reduces time that could be lost in rounding up and installing loose hardware for mounting and locating holding fixtures, the company says.

Read MoreAutomation Cell Maximizes Job Shop Flexibility

Methods Machine Tools’ JobShop Cell is designed for job shops with small to medium lot sizes. The fully integrated production cell combines the drilling, tapping and milling capability of a RoboDrill VMC with a fully interfaced Fanuc six-axis robot for automated loading and unloading.

Read MoreFlexible Pallet Automation Achieves High Spindle Utilization

Toyoda Machinery offers modular and expandable automation with its Flexible Pallet Automation (FPA) systems. The FPA systems enhance the production capabilities of HMCs by automating tasks such as machine loading and unloading.

Read MoreHigh-Penetration Drilling System For Difficult Applications

Allied’s GEN3SYS high-penetration drilling system is designed to tackle difficult drilling applications. The tool design improves hole quality, surface finish and true position, while the replaceable drill insert maximizes machine up-time and reduces setup time.

Read More

.jpg;maxWidth=300;quality=90)