Toolholders

Ringspann Clamping System Features Universal Seating Body

The BKDW clamp series covers a clamping range of 11.9 to 132 mm and offers flange mandrels with maximum actuating forces between 2,300 and 3,840 N, which can transmit torques of 11 to 25 Nm.

Read MoreMaking the Most of Mixed Toolholder Assemblies

While nearly all ER systems will have cross compatibility, they’ll have small differences across manufacturers that make their implementation at the shop level not as standard.

Read MoreTungaloy Grooving Toolholders Provide Highly Stable Machining

TungHeavyGroove includes an enhanced insert clamping design for maximum tool rigidity.

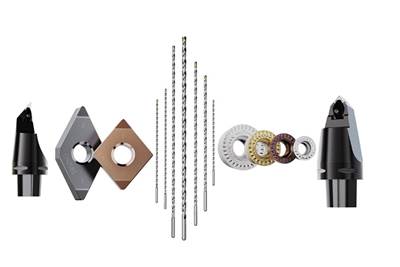

Read MoreSeco Tooling Lineup Promotes Optimized Part Processing

The company’s expanded tooling lineup is aimed at applications ranging from general ISO turning to high-volume hard turning and deep-hole drilling.

Read MoreMarubeni Citizen-Cincom ATC Enables Flexible Machining

Westec 2023: The ATC tooling provides an environment where the tool setting for machining several types of workpieces can be completed in a single setup.

Read MoreFive Common Mistakes Shops Make with ER Collets (And How to Prevent Them)

Collets play a crucial role in the machining process, so proper tool assembly and maintenance is important. Here are five potential pitfalls to avoid when using ER collets.

WatchHaimer Shrink-Fit Machine Features Integrated Cooling

Westec 2023: Power Clamp Air i4.0 Eco provides smooth and clean cooling of all kinds of toolholders or collets by air, without dirt and water residue.

Read MoreRego-Fix Toolholding System Reduces Coolant Consumption

MQL PG collets are designed for machines using one-channel, internal through-spindle MQL systems.

Read MoreLyndex-Nikken Toolholders Offer Stable, Versatile Machining

Polygonal shank toolholders provide a rigid connection between the tool and machine — ideal for all processes both in turning and milling.

Read MoreBig Daishowa Toolholder Increases Precision for Lathes

The Big Capto C3 series provides higher rigidity to minimize vibrations and movement during cutting, improving accuracy and efficiency.

Read More

.png;maxWidth=300;quality=90)