Toolholders

Rego-Fix Toolholding, Metrology Products Increase Accuracy and Efficiency

IMTS 2024: Rego-Fix introduces automated tool clamping units, spindle drawbar force testing tool for increased efficiency and accuracy in measurement.

Read MoreTechniks Tool Group Shrink-Fit Toolholders Enable Flexible Machining

IMTS 2024: Standard, slim nose, coolant ported, thick walled and modular toolholder systems are available through Techniks Tool Group.

Read MoreSowa Shrink-Fit Machine Conserves Toolholder Life

The ShrinkSmart shrink-fit machine’s Smart Coil assesses the distinct resistance of each toolholder to prevent excessive heating.

Read MoreLyndex-Nikken Collets Enable Accurate Small-Diameter Cutting

The MMC Mini-Mini collet chuck is well suited for high-speed machining applications where clearance is needed, such as die mold, aerospace and medical parts.

Read MoreTJ Davies Retention Knobs Enable High Pull Force

The company’s retention knobs are manufactured from American-made 8620 alloy that is treated with hot black oxide to military specifications for protection against corrosion.

Read MoreHorn Toolholder Features Multiple Coolant Connections

The 224 grooving system features internal coolant supply that is fed directly to the insert via the clamping finger or directly to the flank face via a hole.

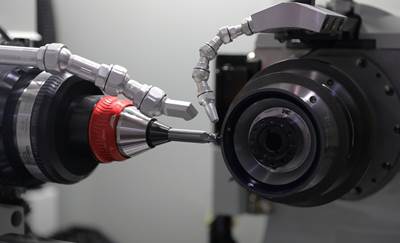

Read MoreANCA, GDS Collet Adapter Improves Grinding Productivity

GDS’ µGrind workholding solution has been customized to suit the requirements of ANCA grinding machines and can be set up in minutes.

Read MoreMonaghan Compensation Chucks Convert Standard ER Holders

Diatool ER Hydraulic Compensation Chucks enable users to convert standard ER holders to a repeatable, steerable hydraulic chuck for more precise machining.

Read MoreT.J. Davies Retention Knobs Maximize Cutting Tool Life

Custom-made retention knobs are sized to fit the machine tool and spindle or toolholder to extend the life of existing machine tool assets.

Read MoreLyndex-Nikken Collet Chuck Increases Gripping Force

SK collet chucks enables for access to tight spaces and provides better clearance, making it ideal for machining complex parts.

Read More

.png;maxWidth=300;quality=90)