Titanium Machining

Water Conservation in Waterjet Machining

This job shop’s water reclamation system also extends the life of waterjet machine hardware.

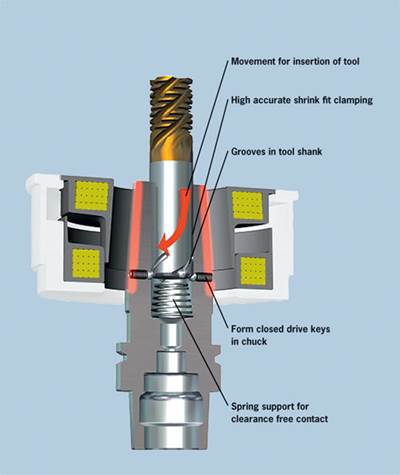

Read MoreTitanium Calls for a Tight Hold on the Tool

Haimer’s SafeLock System provides pull-out protection for tools in high performance cutting such as the machining of titanium.

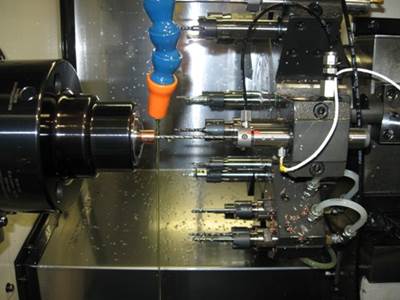

Read MoreDrilling with Modulation Delivers Pecks for Free

A system for center drilling on Swiss-types and other small lathes oscillates the drill up to 1,000 times per second. Cycle time, part quality and predictability all improve.

WatchTaking on Titanium

The challenge for the aerospace machine shop is to produce titanium parts productively and profitably. The challenge for the machine tool builder is to help such shops meet this challenge.

Read MoreThe Promise of "High Cube" Machining

Tool paths and a new tool design provide an alternative to high speed machining for achieving high metal removal rates in hard metals on lighter-duty machines.

Read MoreVideo: Milling Titanium 6-4 Efficiently Without a Heavy Machine

This video of machining titanium at a fast metal removal rate shows the effect of constant-engagement-angle milling.

WatchMachine-Ready Blanks Save Time

According to the supplier, its machine-ready blanks reduce overall part costs.

Read MoreWhat Is The Right Machine Tool For Titanium?

Rather than start with the machine, says Boeing, start with the tooling. For titanium workpieces and other high-value parts, a simple spreadsheet of tools and operations might be the most valuable resource for machining center selection.

Read MoreWhat Is The Best Way To Machine A Deep, Narrow Pocket In Titanium?

Boeing’s answer to a reader question emphasizes the use of high-feed milling tools.

Read MoreWhere Does Diamond Make Sense In Machining Titanium?

Boeing machining experts say one application is drilling Ti-Composite stacks. PCD does well here. The group recently addressed this question submitted through our Aerospace Machining Zone.

Read More.jpg;maxWidth=970;quality=90)

.jpg;maxWidth=300;quality=90)